A kind of preparation method of adhesion promoter for addition type silicone encapsulation glue

An adhesion promoter and silicone technology, which is applied in the field of preparation of an adhesion promoter for addition type silicone encapsulant, can solve the problems of poor compatibility of the encapsulant, environmental pollution, complicated preparation process and the like, and achieve compatibility Good, easy to obtain raw materials, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, the preparation method of the adhesion promoter is: add 104.16 g of tetraethyl orthosilicate, 12.5 g of hydroxyl-terminated polysiloxane with a relative molecular mass of 500, and 22.4 g of hexamethyldisiloxane into the In a 500mL three-neck flask equipped with a thermometer, mechanical stirring and condensing reflux tube, stir well at room temperature, add 0.54g hydrochloric acid and 54g deionized water, react at 20°C for 7h, then add 94.53g 3-(2,3-epoxy Propoxy)propyltrimethoxysilane, 24.83g 3-methacryloxypropyltrimethoxysilane and 18.2g hexamethyldisiloxane, react at 90°C for 2h, and finally remove low boilers , to prepare Adhesion Promoter 1.

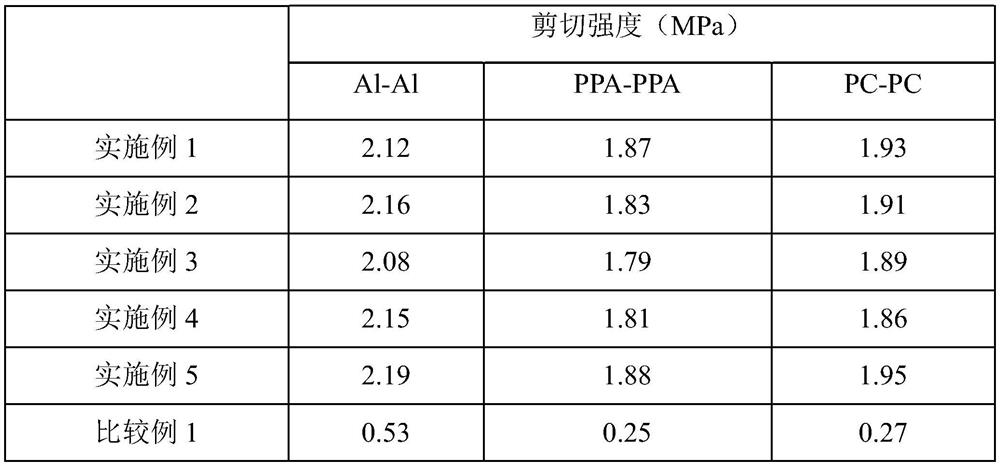

[0021] The method for preparing the addition-type silicone encapsulant sample is as follows: 100 parts by mass of vinyl methyl silicone resin with a vinyl content of 3.2 wt%, 80 parts by mass of vinyl silicone oil with a viscosity of 5000mPa·s, 11 parts by mass of active hydrogen Hydrogen-containing silicone...

Embodiment 2

[0023] In this example, the preparation method of the adhesion promoter is: add 76.11g of methyl orthosilicate, 10g of hydroxyl-terminated polysiloxane with a relative molecular weight of 1000 and 20.42g of trimethylmethoxysilane into a A 500mL three-necked flask with a thermometer, a mechanical stirrer and a condensing reflux tube, stirred evenly at room temperature, added 0.9g of acetic acid and 18g of deionized water, reacted at 40°C for 3h, then added 55.08g of 3-(2,3-epoxypropylene Oxy)propylmethyldimethoxysilane, 58.08g 3-methacryloxypropylmethyldimethoxysilane and 14.05g trimethylmethoxysilane were reacted at 80°C for 4h, and finally Removal of low boilers yields Adhesion Promoter 2.

[0024] The method for preparing the addition-type silicone encapsulant sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 2. The properties of the samples are shown in Table 1 and Table 2.

Embodiment 3

[0026] In this example, the preparation method of the adhesion promoter is: add 89.15g of methyltriethoxysilane, 15g of hydroxyl-terminated polysiloxane with a relative molecular mass of 3000 and 12.32g of trimethylmethoxysilane into the In a 500mL three-neck flask equipped with a thermometer, mechanical stirring and condensing reflux tube, stir well at room temperature, add 0.45g of sulfuric acid and 27g of deionized water, react at 55°C for 2h, then add 41.76g of 3-(2,3-epoxy Propoxy)propyltriethoxysilane, 101.65g 3-methacryloxypropyltriethoxysilane and 11.33g trimethylmethoxysilane were reacted at 70°C for 3h, and finally the low Boiler, obtained adhesion promoter 3.

[0027] The method for preparing the addition-type silicone encapsulating adhesive sample in this example is basically the same as that in Example 1, except that the adhesion promoter 1 in Example 1 is changed to adhesion promoter 3. The properties of the samples are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com