High-thermal-conductivity die-casting aluminum alloy material and manufacturing method thereof

A technology of casting aluminum alloy and high thermal conductivity, which is applied in the field of aluminum alloy materials, can solve problems such as inability to meet the requirements of technological development, and achieve the effect of reasonable composition ratio and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a high thermal conductivity die-casting aluminum alloy material, comprising the following steps:

[0035] (1) Put aluminum ingot and nickel element additive into melting furnace, heat it to melt into metal solution;

[0036] (2) When the temperature reaches 830°C-860°C, add iron element additives to the metal solution to completely melt and complete the alloying;

[0037] (3) cooling the metal solution to 780-800°C;

[0038] (4) adding scouring agent for refining purification and slag removal;

[0039] (5) adding magnesium element additive, and adjusting the weight ratio of magnesium and silicon;

[0040] (6) add lanthanum rare earth additive and carry out deterioration;

[0041] (7) Cast aluminum alloy ingots with the temperature of the molten aluminum in the range of 770-780°C.

[0042] The high thermal conductivity die-casting aluminum alloy material of the embodiment of the present invention has a reason...

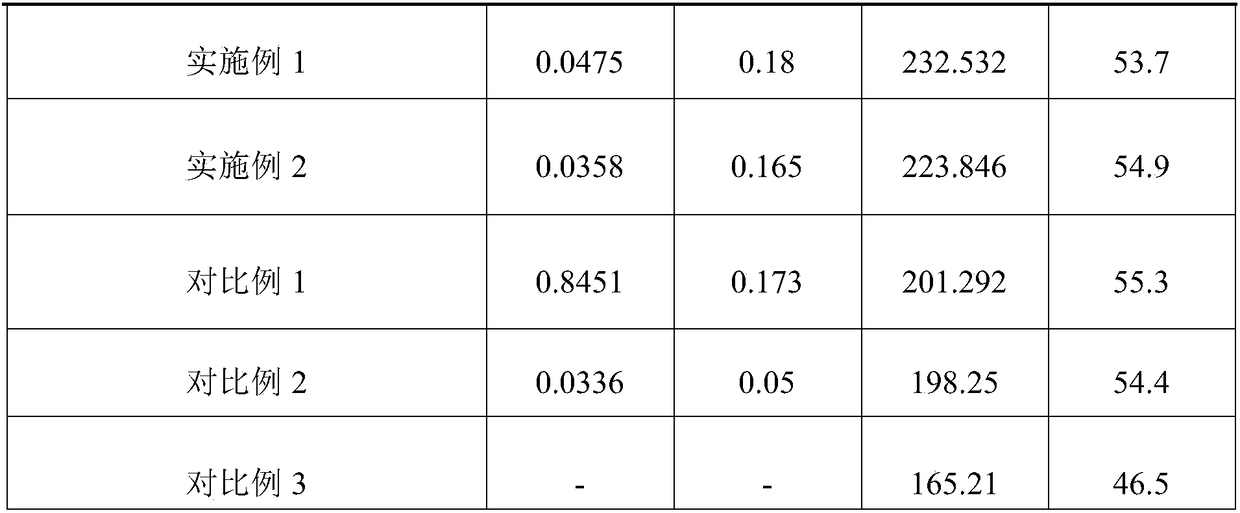

Embodiment 1

[0047] Raw material ratio, calculated by weight percentage: silicon, 0.0782% content; iron, 1.055% content; copper, 0.0064% content; manganese, 0.0002% content; magnesium, 0.0028% content, zinc, 0.038% content , nickel, content 0.547%; lanthanum, content 0.18%, cobalt, content ≤0.0001%; lead, content ≤0.00068%; tin, content ≤0.00096%; cadmium, content ≤0.0001%; More than 0.3%; the balance is aluminum.

[0048] Prepare the alloy according to the above ratio, and the steps are as follows:

[0049] Put aluminum ingots and nickel element additives into the melting furnace, heat it to melt it into a metal solution, and make the temperature of the metal solution reach 830°C, then add iron element additives to the molten metal to completely melt and complete the alloying; then cool down to 790°C, then add scouring agent for refining purification and slag removal; use nitrogen to degas the metal solution, then take samples of the metal solution to check the composition, add magnesi...

Embodiment 2

[0051] Raw material ratio, calculated by weight percentage: silicon, content 0.0463%; iron, content 0.9367%; copper, content 0.0017%; manganese, content 0.0347%; magnesium, content 0.0022%, zinc, content 0.0155% , nickel, content 0.4623%; lanthanum, content 0.165%; cobalt, content ≤0.0001%; lead, content ≤0.00089%; tin, content ≤0.0001%; cadmium, content ≤0.0001%; More than 0.3%; the balance is aluminum.

[0052] Prepare the alloy according to the above ratio, and the steps are as follows:

[0053] Put aluminum ingots and nickel element additives into the melting furnace, heat it to melt it into a metal solution, and make the temperature of the metal solution reach 830°C, then add iron element additives to the molten metal to completely melt and complete the alloying; then cool down to 790°C, then add scouring agent for refining purification and slag removal; use nitrogen to degas the metal solution, then take samples of the metal solution to check the composition, add ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com