Production process preventing seam broken in linerboard

A production process, a technology for containerboard paper, applied in paper, papermaking, papermaking and other directions, can solve the problems of paper surface smoothness, poor cleanliness, slow drying speed, high cost, and achieve excellent strength and surface cleanliness. The effect of solving the explosion line cracking and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

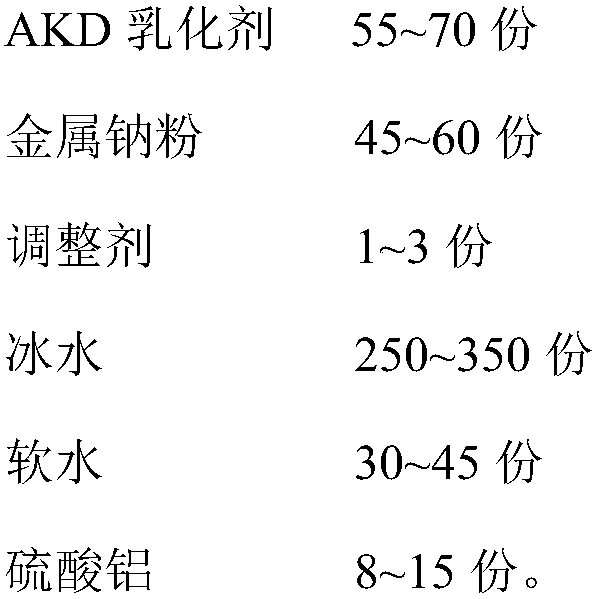

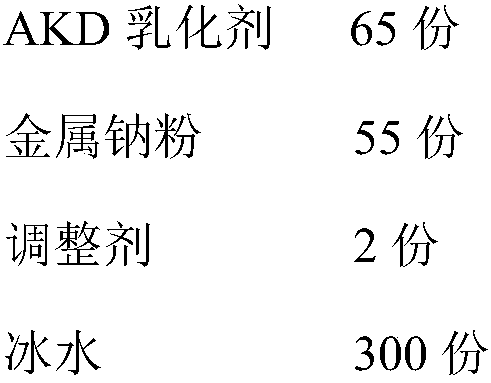

[0037] A kind of production technology that prevents the cardboard paper bursting line of the present embodiment, comprises the following steps:

[0038] Step 1, Pulping:

[0039] The good pulp after the waste paper raw material is crushed by the pulper is transported to the high-concentration desander for sand removal, and the good pulp obtained is transported to the unloading tower;

[0040] Step 2, screening of slurry:

[0041] (1) After the fine pulp of the unloading tower passes through the first-stage coarse screen, the second-stage coarse screen and the third-stage coarse screen in sequence, the fine pulp obtained by the coarse screen is obtained;

[0042] (2) Pump the fine stock from the coarse screen to the medium-concentration desander, and transport the fine stock after desanding to the grading screen to obtain long fibers and short fibers respectively;

[0043] (3) After the long fibers are sequentially transported to the long fiber fine screen, the long fiber de...

Embodiment 2

[0061] A kind of production technology that prevents the cardboard paper bursting line of the present embodiment, comprises the following steps:

[0062] Step 1, Pulping:

[0063] The good pulp after the waste paper raw material is crushed by the pulper is transported to the high-concentration desander for sand removal, and the good pulp obtained is transported to the unloading tower;

[0064] Step 2, screening of slurry:

[0065] (1) After the fine pulp of the unloading tower passes through the first-stage coarse screen, the second-stage coarse screen and the third-stage coarse screen in sequence, the fine pulp obtained by the coarse screen is obtained;

[0066] (2) Pump the fine stock from the coarse screen to the medium-concentration desander, and transport the fine stock after desanding to the grading screen to obtain long fibers and short fibers respectively;

[0067] (3) After the long fibers are sequentially transported to the long fiber fine screen, the long fiber de...

Embodiment 3

[0085] A kind of production technology that prevents the cardboard paper bursting line of the present embodiment, comprises the following steps:

[0086] Step 1, Pulping:

[0087] The good pulp after the waste paper raw material is crushed by the pulper is transported to the high-concentration desander for sand removal, and the good pulp obtained is transported to the unloading tower;

[0088] Step 2, screening of slurry:

[0089] (1) After the fine pulp of the unloading tower passes through the first-stage coarse screen, the second-stage coarse screen and the third-stage coarse screen in sequence, the fine pulp obtained by the coarse screen is obtained;

[0090] (2) Pump the fine stock from the coarse screen to the medium-concentration desander, and transport the fine stock after desanding to the grading screen to obtain long fibers and short fibers respectively;

[0091] (3) After the long fibers are sequentially transported to the long fiber fine screen, the long fiber de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com