Insulating member of station door assembly

A platform door and assembly technology, applied to building components, door leaves, stations, etc., can solve problems such as operational safety hazards, stray current corrosion of steel bars, electric shock hazards for passengers, etc., to meet the requirements of force, reliability, and performance Stable and reliable, the effect of avoiding electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

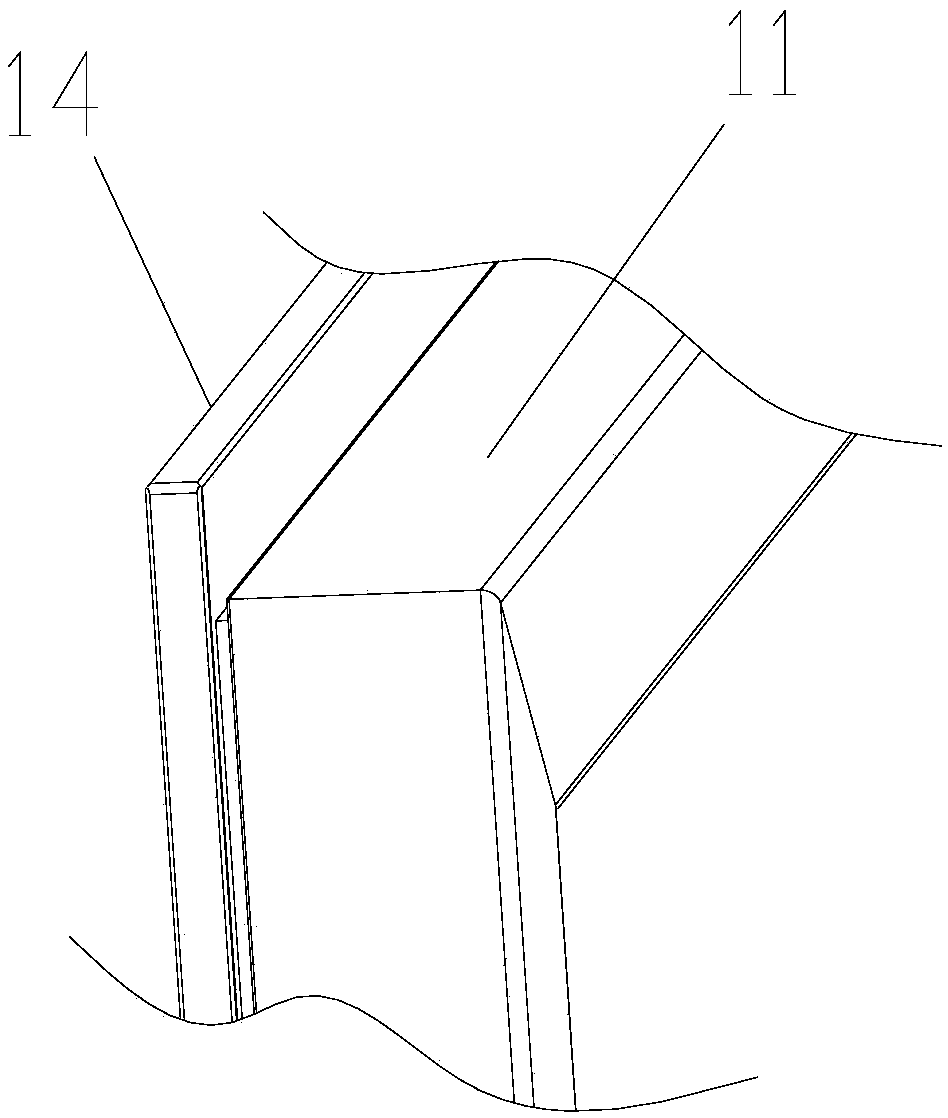

Embodiment 1

[0039] The insulating platform door assembly component of the present invention is a platform door body, and the platform door body includes a door frame insulating layer, a door frame profile used to construct the platform door body and glass parts used to construct the platform sliding door. The door frame profile and the glass parts are assembled into a platform door body, the door frame insulating layer is covered outside the door frame profile, and the surface of the door frame insulating layer is provided with an anti-corrosion and anti-ultraviolet protective layer. The insulating material used for the insulating layer of the door frame is epoxy resin or unsaturated resin or polyurethane material. Between the insulating layers of adjacent door frames, the joints are filled with insulating materials. The thickness of the insulating layer of the door frame is 2.5mm to 3.5mm, and the insulating layer of the door frame can directly face the passengers, which plays the main r...

Embodiment 2

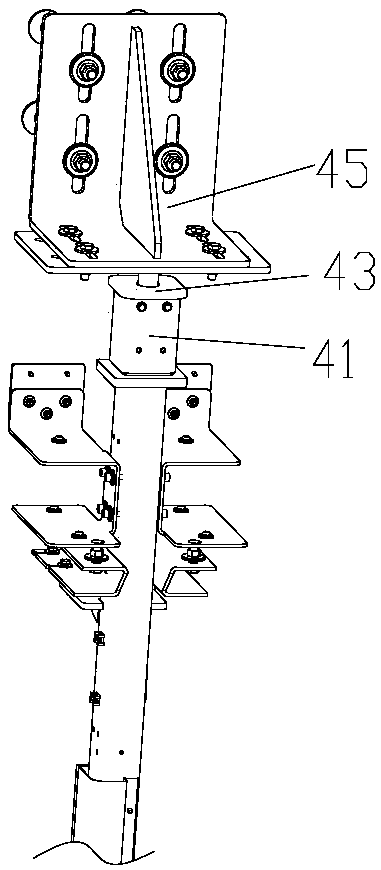

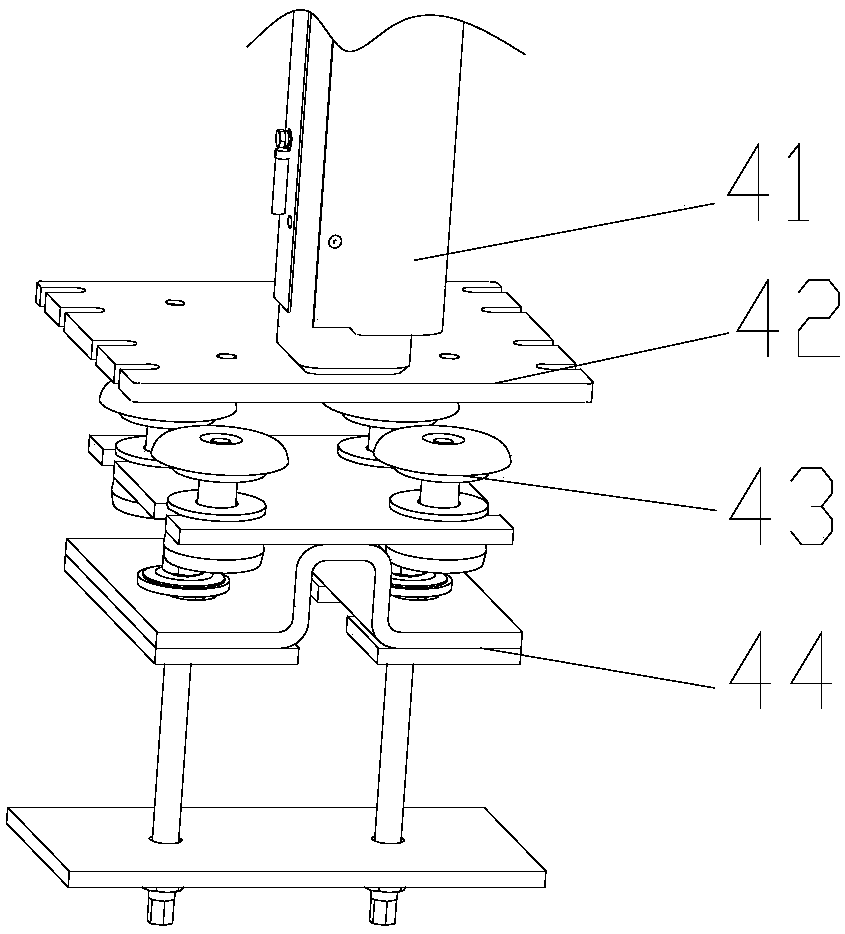

[0042] The insulating platform door assembly component of the present invention is a column, and the column includes a column insulation layer, a telescopic device and a bottom plate for building the column, and a column profile for building the column; the telescopic device, the column profile and the bottom plate are arranged from top to bottom .

[0043] The profile of the column is a steel profile, and the insulating layer of the column is a layer of composite insulating material. The composite insulating material layer is made of insulating resin and reinforced fiber. The column insulation layer and the column insulation layer are co-extruded into the column main body. On the basis of meeting the existing design force requirements, the surface insulation material ensures that the door The surface insulation value of the body, and the surface insulation material meets the requirements of low smoke, halogen-free, flame retardant, and the strength, water absorption and servi...

Embodiment 3

[0049]The insulating platform door assembly components of the present invention are a platform door body and a column.

[0050] The platform door body consists of door frame insulation, door frame profiles for the construction of the platform door body and glass parts for the construction of the platform sliding door. The door frame profile and the glass parts are assembled into a platform door body, the door frame insulating layer is covered outside the door frame profile, and the surface of the door frame insulating layer is provided with an anti-corrosion and anti-ultraviolet protective layer. The insulating material used for the insulating layer of the door frame is epoxy resin or unsaturated resin or polyurethane material. Between the insulating layers of adjacent door frames, the joints are filled with insulating materials. The thickness of the insulating layer of the door frame is 2.5mm to 3.5mm, and the insulating layer of the door frame can directly face the passenge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com