Preparation methodand application of non-noble metal-loaded porous carbon material

A technology of porous carbon materials and non-precious metals, which is applied in the field of preparation of non-precious metal-loaded porous carbon materials, can solve the problems of cumbersome operation, large environmental pollution, and wide pore size distribution, and achieve good electrochemical performance, high specific surface area, and high thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

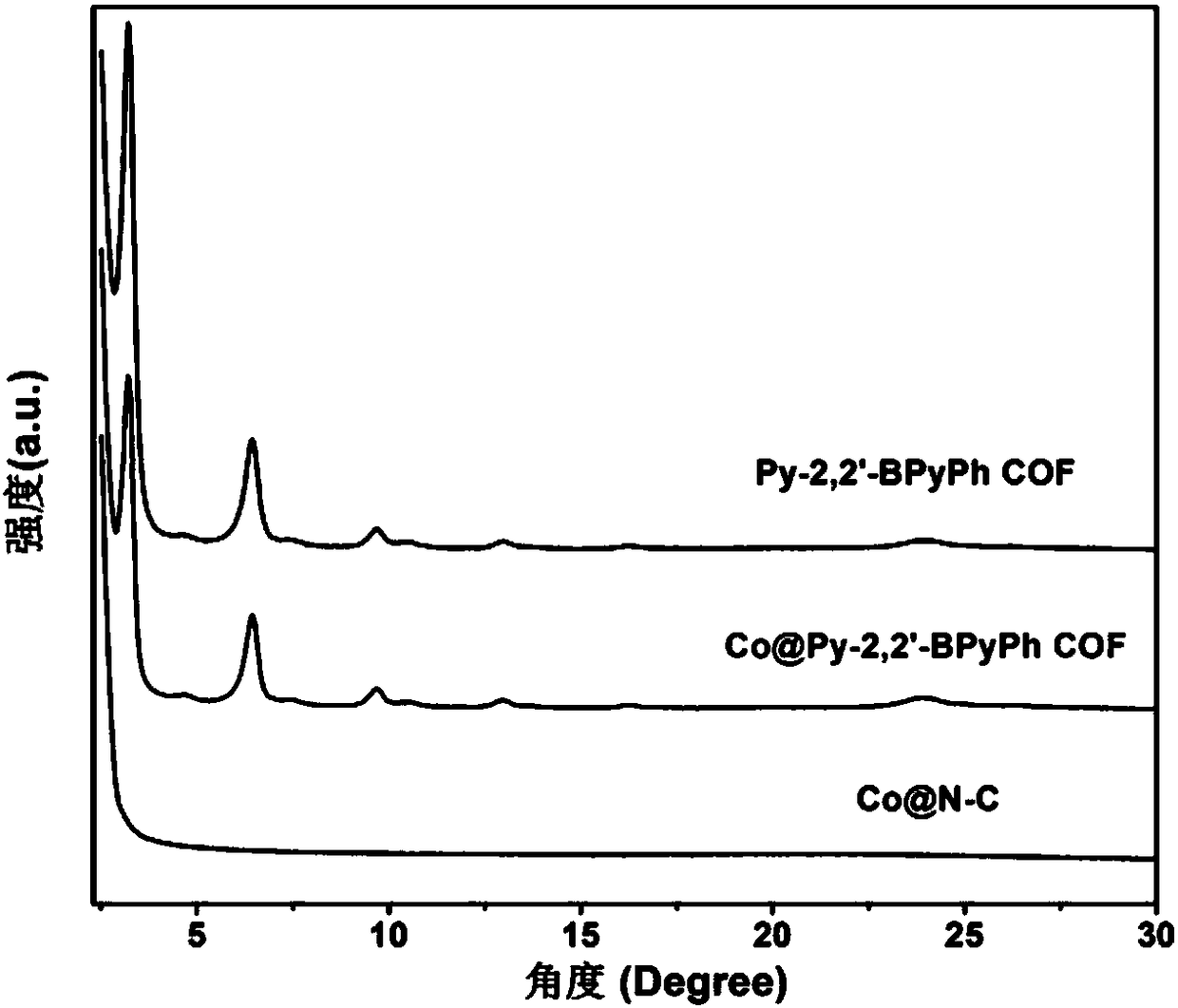

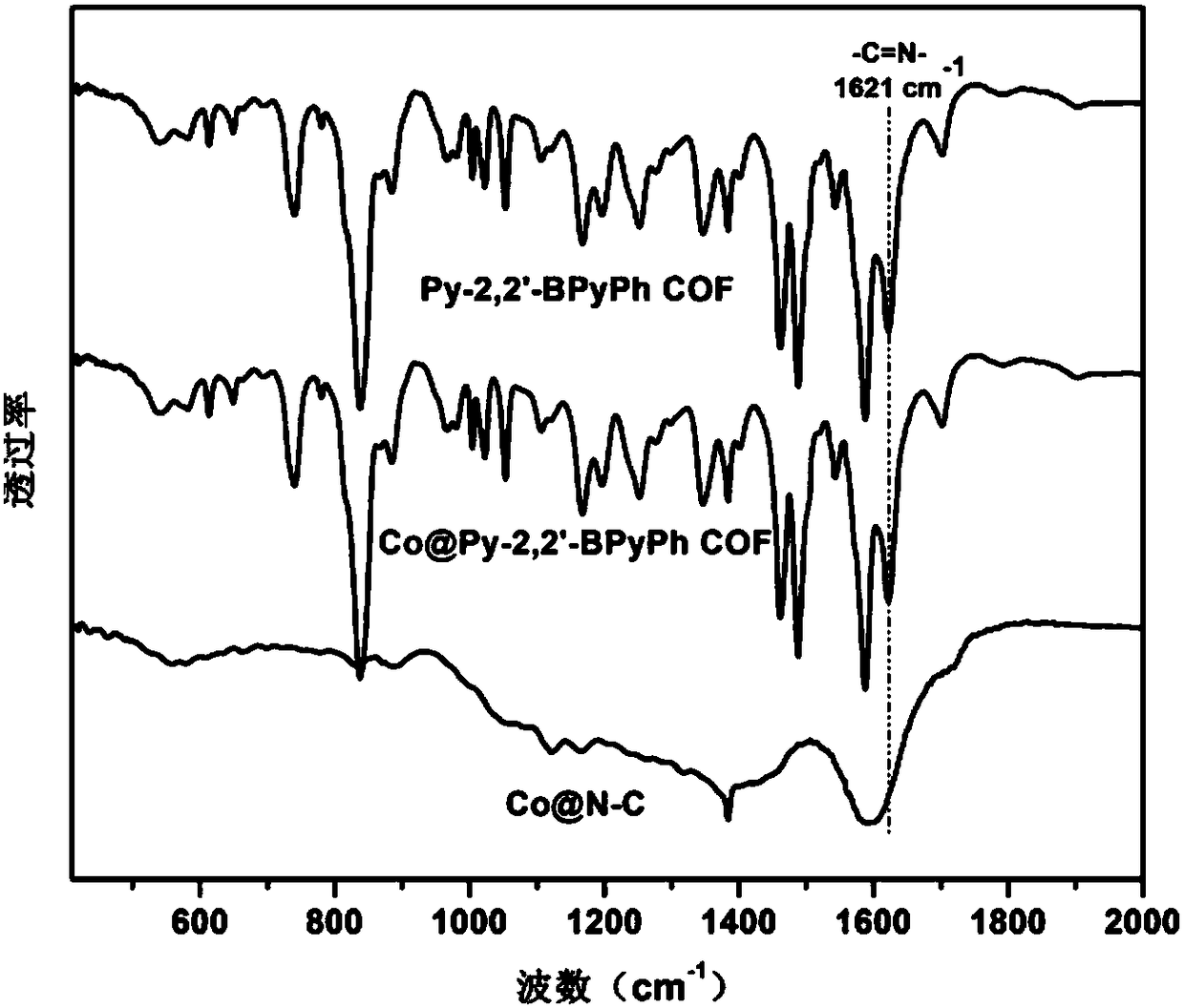

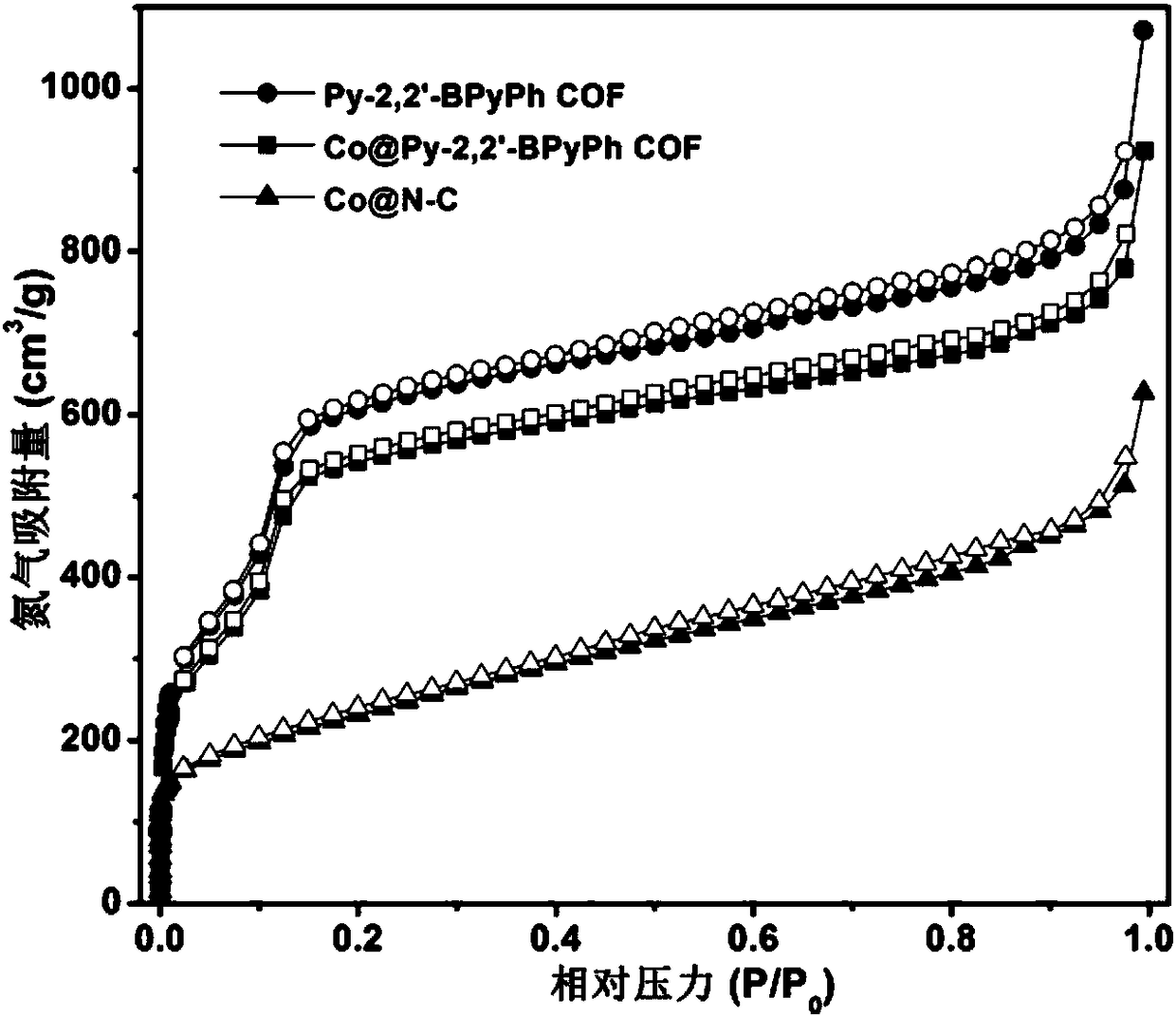

[0035] The porous carbon material loaded with non-noble metal cobalt and the corresponding supercapacitor working electrode were prepared according to the following steps:

[0036] (1) According to the published synthesis method, synthesize and prepare the covalent organic framework material containing bipyridine group, Py-2,2'-BPyPh COF, the specific operation is as follows:

[0037] Add 8.5 mg (0.04 mmol) of 2,2'-bipyridine-5,5'-dicarbaldehyde (2,2'-BPy DCA) and 11.3 mg (0.02 mmol) of tetrakis(p-phenylamino)pyrene (PyTTA) To the ampoule, add 0.5mL mesitylene and 0.5mL 1,4-dioxane, mix well by ultrasonic, then add 0.1mL (6mol / L) acetic acid aqueous solution, place the ampoule in liquid nitrogen for freezing , evacuate until the pressure inside the bottle is less than 3Pa, seal the tube with flame, put it in an oven after sealing, and raise the temperature to 120°C to react for 3 days. After the reaction was completed, it was filtered with suction, and the obtained solid was ...

Embodiment 2

[0053] The porous carbon material loaded with non-noble metal cobalt and the corresponding supercapacitor working electrode were prepared according to the following steps:

[0054] (1) According to the published synthesis method, synthesize and prepare the covalent organic framework material containing bipyridine group, Py-2,2'-BPyPh COF, the specific operation is as follows:

[0055] Add 8.5 mg (0.04 mmol) of 2,2'-bipyridine-5,5'-dicarbaldehyde (2,2'-BPy DCA) and 11.3 mg (0.02 mmol) of tetrakis(p-phenylamino)pyrene (PyTTA) To the ampoule, add 0.5mL mesitylene and 0.5mL 1,4-dioxane, mix well by ultrasonic, then add 0.1mL (6mol / L) acetic acid aqueous solution, place the ampoule in liquid nitrogen for freezing , evacuate until the pressure inside the bottle is less than 3Pa, seal the tube with flame, put it in an oven after sealing, and raise the temperature to 120°C to react for 3 days. After the reaction was completed, it was filtered with suction, and the obtained solid was ...

Embodiment 3

[0063] The porous carbon material loaded with non-noble metal cobalt and the corresponding supercapacitor working electrode were prepared according to the following steps:

[0064] (1) According to the published synthesis method, synthesize and prepare the covalent organic framework material containing bipyridine group, Py-2,2'-BPyPh COF, the specific operation is as follows:

[0065] Add 8.5 mg (0.04 mmol) of 2,2'-bipyridine-5,5'-dicarbaldehyde (2,2'-BPy DCA) and 11.3 mg (0.02 mmol) of tetrakis(p-phenylamino)pyrene (PyTTA) To the ampoule, add 0.5mL mesitylene and 0.5mL 1,4-dioxane, mix well by ultrasonic, then add 0.1mL (6mol / L) acetic acid aqueous solution, place the ampoule in liquid nitrogen for freezing , evacuate until the pressure inside the bottle is less than 3Pa, seal the tube with flame, put it in an oven after sealing, and raise the temperature to 120°C to react for 3 days. After the reaction was completed, it was filtered with suction, and the obtained solid was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com