Catalyst for oil hydrogenation to hydrocarbon fuels and its preparation and application

A technology for hydrogenation of hydrocarbon fuels and oils, which is applied in molecular sieve catalysts, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. It can solve the problem of reduced selectivity and yield of target products, increased probability, and probability of insertion end cracking and other problems, to achieve the effect of improving freezing point, high isomer selectivity, and increasing diesel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

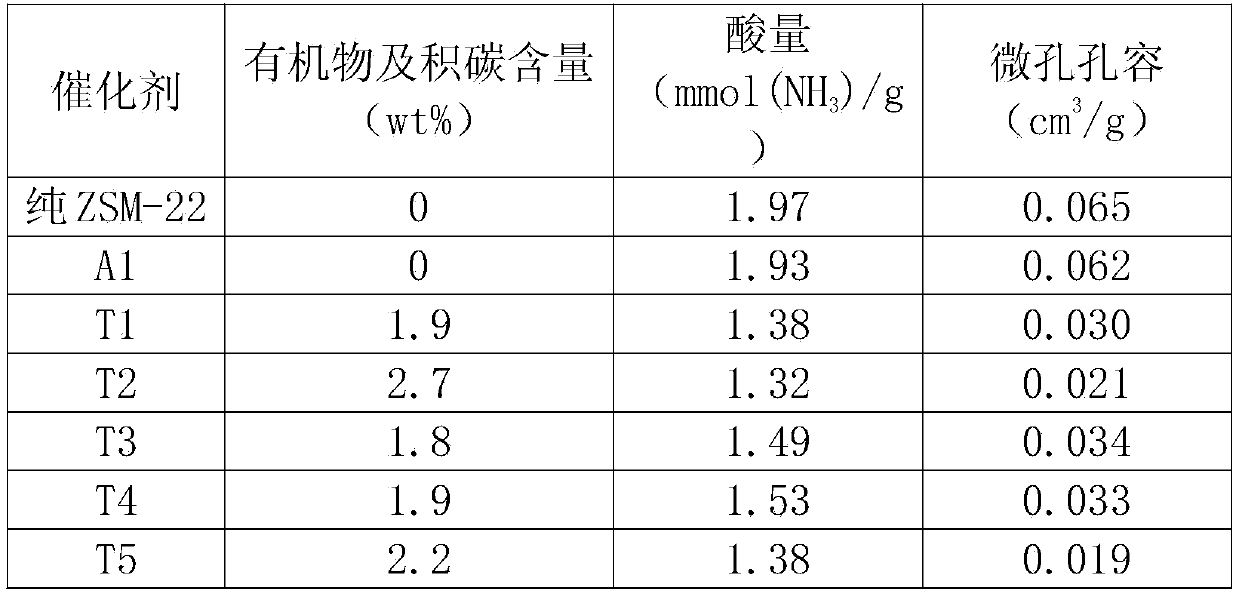

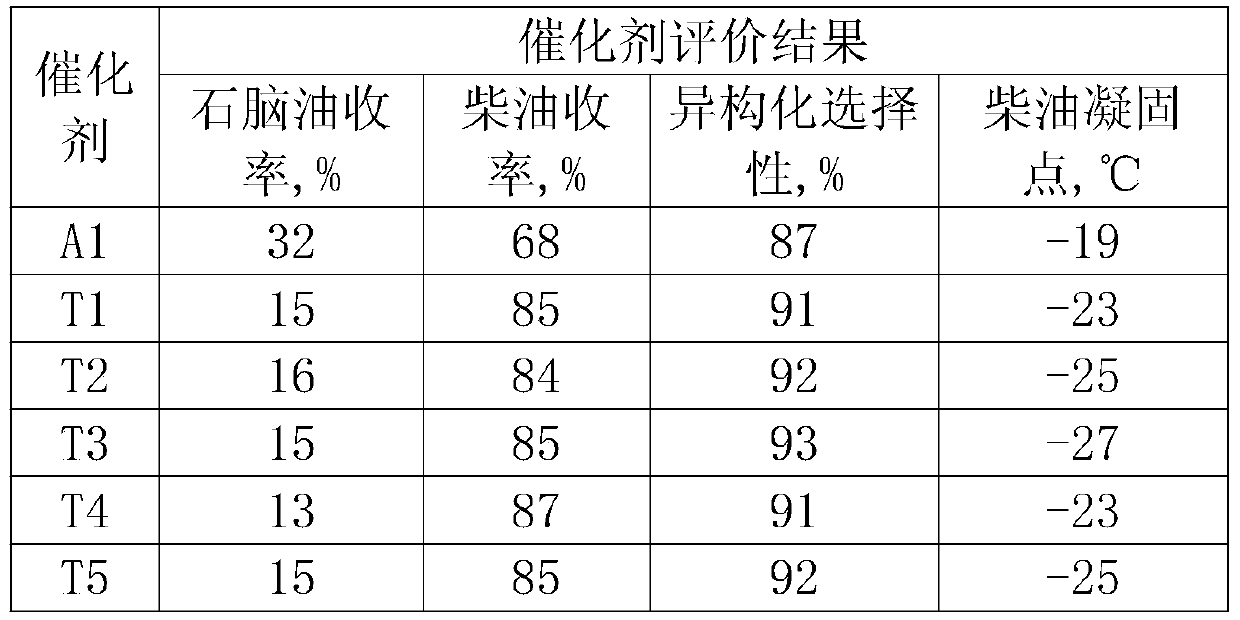

[0070] Take 120g of the ZSM-22 molecular sieve raw powder containing the template, and roast it under an air atmosphere at 550°C for 24h to obtain 100g of the ZSM-22 molecular sieve from which the template has been completely removed; take 30g of pseudoboehmite (alumina hydrate) and Mix well, add 80g 5wt% HNO 3 solution, kneaded, molded with extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfuryl alcohol and 100mL ethanol were mixed and stirred evenly at 25°C, and 1g oxalic acid was added to it , after dissolving completely, obtain monomer solution; Take 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, obtain the carrier precursor of adsorption monomer solution after filtration and dry 0.5h at 120 ℃ (while drying, The polymer monomer furfuryl alcohol adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), and then...

Embodiment 2

[0072] Take 120g of the ZSM-22 molecular sieve raw powder containing the template, and roast it under an air atmosphere at 550°C for 24h to obtain 100g of the ZSM-22 molecular sieve from which the template has been completely removed; take 30g of pseudoboehmite (alumina hydrate) and Mix well, add 80g 5wt% HNO 3 solution, kneaded, shaped by extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfural and 100mL ethanol were mixed and stirred evenly at 25°C, and 1g oxalic acid was added to it , after dissolving completely, obtain monomer solution; Take 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, obtain the carrier precursor of adsorption monomer solution after filtration and dry 0.5h at 120 ℃ (while drying, The polymer monomer furfural adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), and then placed in a quart...

Embodiment 3

[0074] Take 120g of the ZSM-22 molecular sieve raw powder containing the template agent, and roast it under an air atmosphere at 550°C for 24h to obtain 100g of the ZSM-22 molecular sieve from which the template agent has been completely removed; take 20g of pseudoboehmite (alumina hydrate) and Mix well, add 80g 5wt% HNO 3 solution, kneaded, formed with extruder, dried naturally, then dried at 120°C for 4h, and roasted at 550°C for 12h to obtain the carrier precursor; 100mL furfural and 50mL ethanol were mixed and stirred at 25°C, and 5mL Hydrochloric acid, after dissolving completely, obtains monomer solution; Get 50g carrier precursor and mix with 50g monomer solution, place 6h under 25 ℃, after filtering, obtain the carrier precursor of adsorption monomer solution and dry at 120 ℃ for 0.5h (while drying , the polymer monomer furfural adsorbed by the carrier precursor undergoes spontaneous condensation reaction under heating and acidic environment), and then placed in a quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com