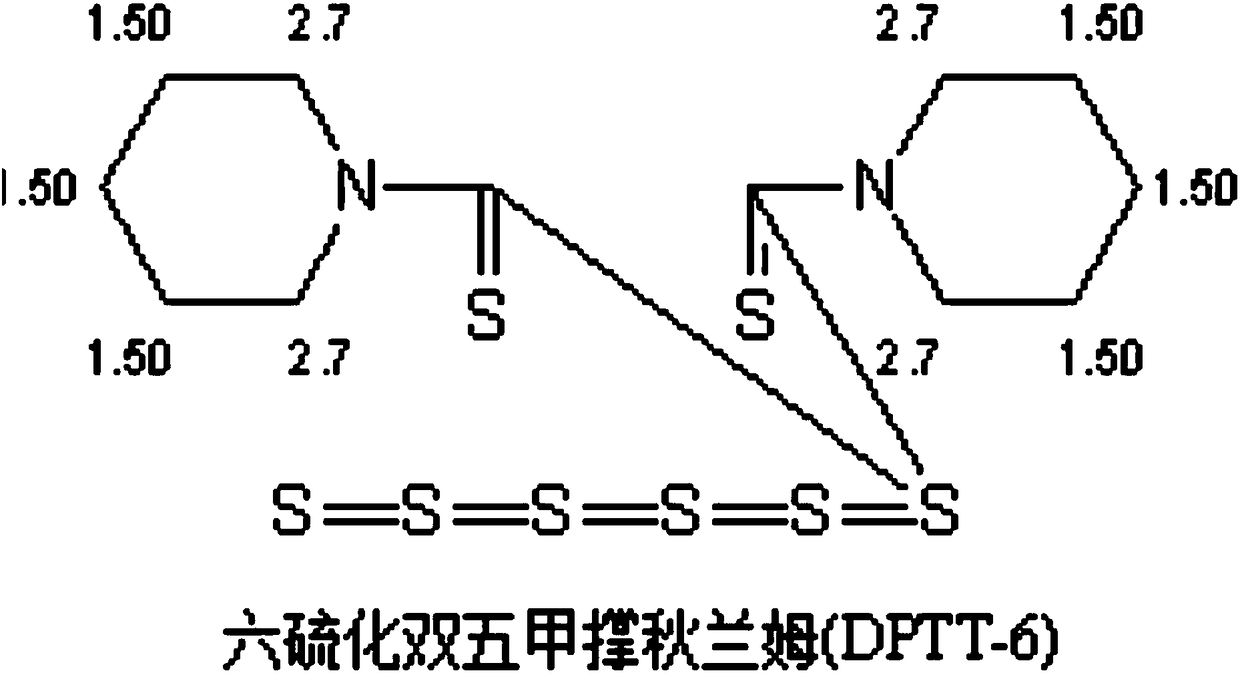

Preparation method of thiofide DPTT-6

A DPTT-6, rubber vulcanization technology, applied in the direction of organic chemistry, can solve the problems of high environmental protection pressure, no water, difficult reaction, etc., and achieve the effect of zero pollution emission, high product yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to one aspect of the present invention, a kind of preparation method of rubber vulcanization accelerator DPTT-6, described preparation method comprises the following steps: join sulfur, hexahydropyridine and surfactant in low carbon alcohol solvent and mix, subsequently, Add carbon disulfide and hydrogen peroxide dropwise and react at elevated temperature to obtain rubber vulcanization accelerator DPTT-6.

[0033] The preparation method of the rubber vulcanization accelerator DPTT-6 of the present invention is to add sulfur, hexahydropyridine and surfactant into a low-carbon alcohol solvent and mix evenly, then, add carbon disulfide and hydrogen peroxide dropwise in sequence and react at elevated temperature to prepare the rubber vulcanization accelerator DPTT-6. The above preparation method adopts low-carbon alcohol which is low-toxic, cheap, easy to recycle and apply mechanically as a solvent, and synthesizes dipentamethylenethiuram hexasulfide (DPTT-6) thro...

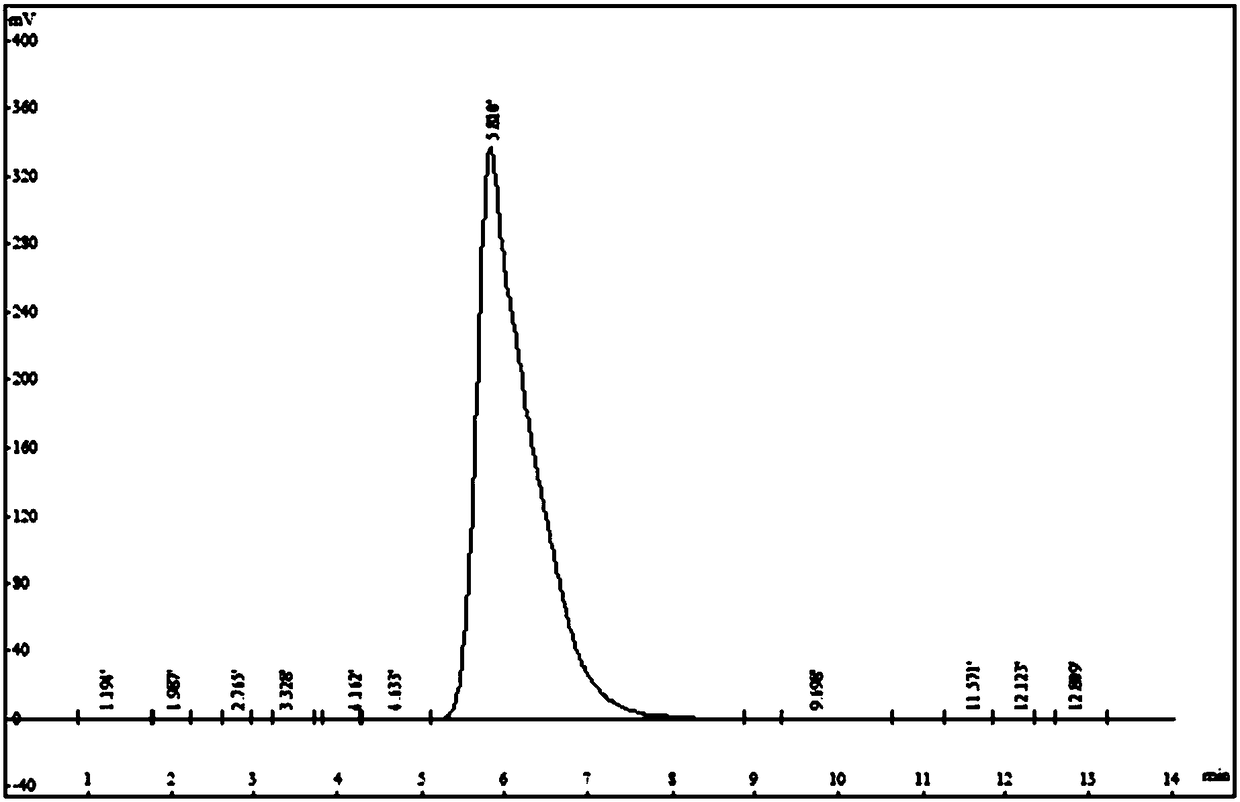

Embodiment 1

[0059] A kind of preparation method of rubber vulcanization accelerator DPTT-6, described preparation method comprises the following steps:

[0060] First, under normal pressure, add 250ml of ethanol and 14.0g of sulfur into a 1000ml four-neck flask for stirring and mixing for 30 minutes; then add 19.6g of hexahydropyridine and 0.98g of trimethyloctadecylammonium chloride , control the temperature at 18°C, start to add 17.87g of carbon disulfide dropwise, control the temperature at 18°C during the dropping process, and add the time for 1.5h; after the dropwise addition, control the temperature at 18°C for 1.0h;

[0061] Subsequently, the temperature was raised to 22°C, and a mixed solution of 17.07g of hydrogen peroxide and 108.17ml of ethanol was added dropwise, and the rate of addition was controlled so that the reaction temperature was 22°C, and the dropping time was 3.5h; then, the reaction was kept for 0.5h;

[0062] Finally, the temperature of the obtained reaction s...

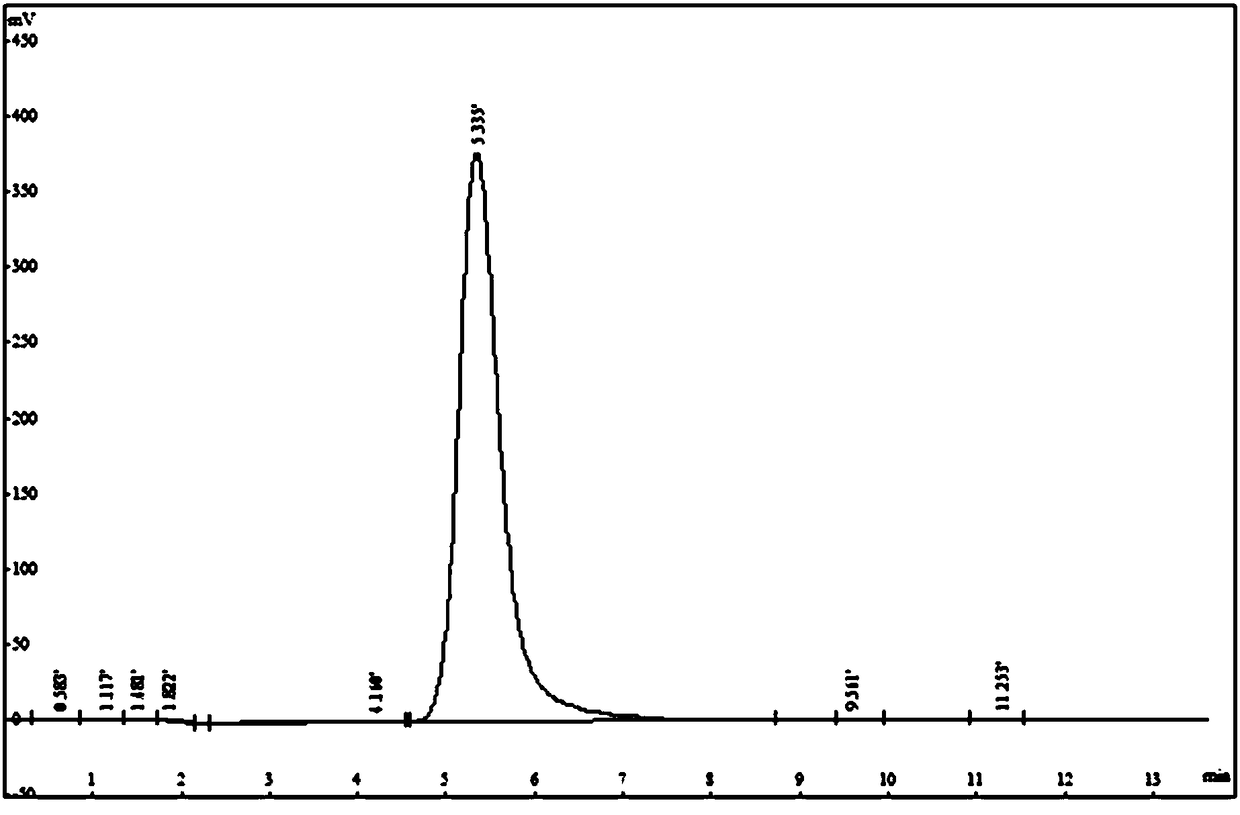

Embodiment 2

[0068] A kind of preparation method of rubber vulcanization accelerator DPTT-6, described preparation method comprises the following steps:

[0069] First, under normal pressure, add 250ml of ethanol and 14.0g of sulfur into a 1000ml four-neck flask for stirring and mixing for 30 minutes; then add 22.5g of hexahydropyridine and 0.98g of trimethyloctadecylammonium chloride , control the temperature at 18°C, start to add 19.87g of carbon disulfide dropwise, control the temperature at 18°C during the dropping process, and add the time for 1.5h; after the dropwise addition, control the temperature at 18°C for 1.0h;

[0070] Subsequently, the temperature was raised to 22°C, and a mixed solution of 17.07g of hydrogen peroxide and 108.17ml of ethanol was added dropwise, and the rate of addition was controlled so that the reaction temperature was 22°C, and the dropping time was 3.5h; then, the reaction was kept for 0.5h;

[0071] Finally, the temperature of the obtained reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation vapor pressure | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com