Low-warpage high-temperature-resistant conductive liquid crystal polyester composite material and preparation method thereof

A technology of liquid crystal polyester and composite materials, applied in the field of low warpage and high temperature resistant conductive liquid crystal polyester composite materials and its preparation, and liquid crystal polyester composite materials, can solve problems such as research on the warpage performance of high temperature resistant conductive composite materials, and achieve Good dimensional stability, high modulus, and small warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

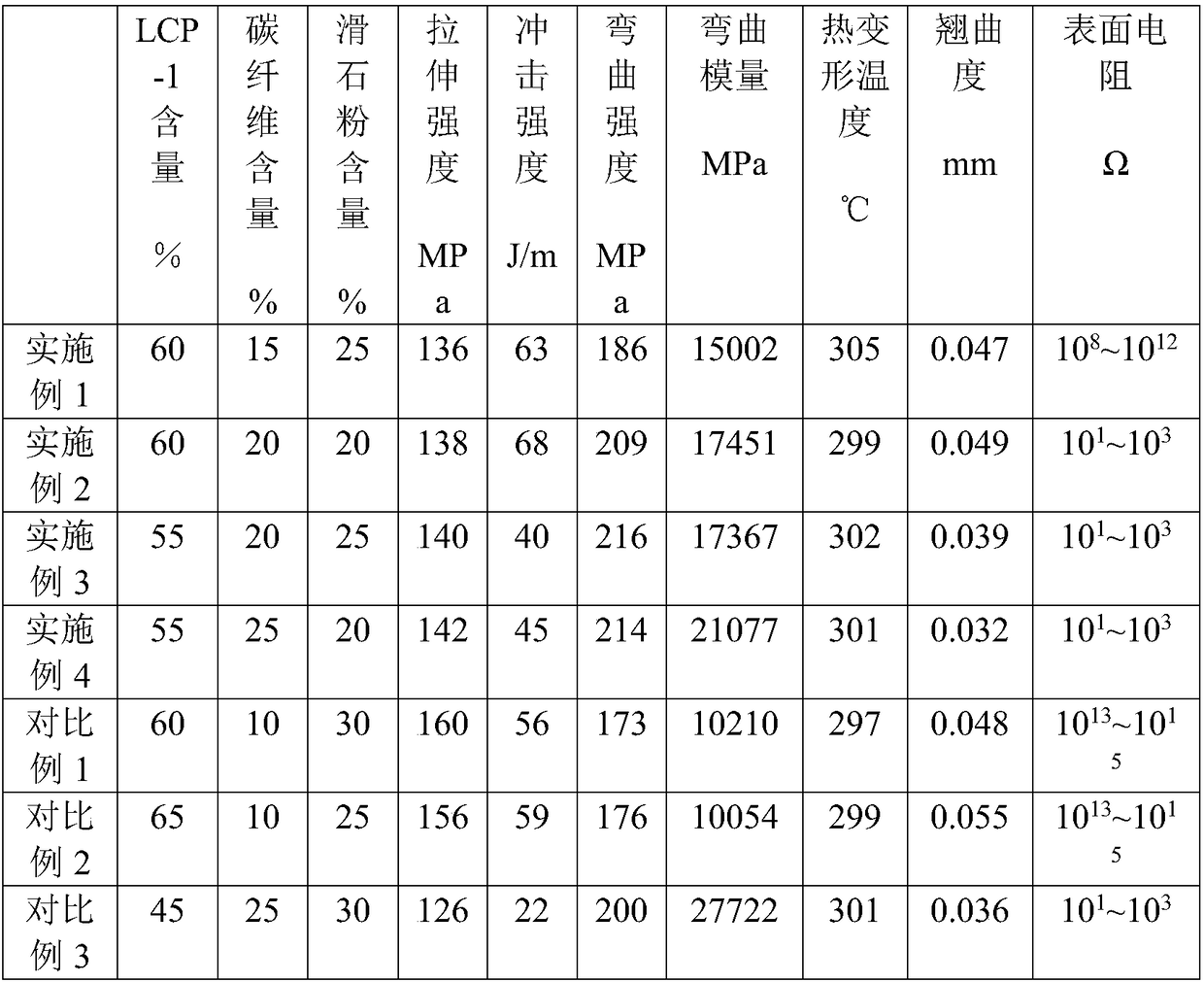

[0033] 60 parts by weight of LCP, 15 parts by weight of carbon fiber (CT70P006-PUY, manufactured by Toho, number average fiber length: 6 mm, number average fiber diameter: 6 μm, the same below), 25 parts by weight of talcum powder (HM4, manufactured by Imifabi, 1250 mesh) was mixed in a tumbler, and then, the mixture was pelletized with a twin-screw extruder at a barrel temperature of 355° C. to obtain pellets composed of a liquid crystal polyester resin composition. The obtained pellets were injection molded by a NEX110T type injection molding machine (manufactured by Nissei Plastic Industrial Co., ltd) at a barrel temperature of 365°C and a mold temperature of 120°C. The results are listed in Table 2.

Embodiment 2

[0035] 60 parts by weight of LCP, 20 parts by weight of carbon fiber (CT70P006-PUY, manufactured by Toho, number average fiber length: 6mm, number average fiber diameter: 6 μm, the same below), 20 parts by weight of talcum powder (HM4, manufactured by Imifabi, 1250 mesh) was mixed in a tumbler, and then, the mixture was pelletized with a twin-screw extruder at a barrel temperature of 355° C. to obtain pellets composed of a liquid crystal polyester resin composition. The obtained pellets were injection molded by a NEX110T type injection molding machine (manufactured by Nissei Plastic Industrial Co., ltd) at a barrel temperature of 365°C and a mold temperature of 120°C. The results are listed in Table 2.

Embodiment 3

[0037] 55 parts by weight of LCP, 20 parts by weight of carbon fiber (CT70P006-PUY, manufactured by Toho, number average fiber length: 6 mm, number average fiber diameter: 6 μm, the same below), 25 parts by weight of talcum powder (HM4, manufactured by Imifabi, 1250 mesh) was mixed in a tumbler, and then, the mixture was pelletized with a twin-screw extruder at a barrel temperature of 355° C. to obtain pellets composed of a liquid crystal polyester resin composition. The obtained pellets were injection molded by a NEX110T type injection molding machine (manufactured by Nissei Plastic Industrial Co., ltd) at a barrel temperature of 365°C and a mold temperature of 120°C. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com