Carbon fiber surface oiling agent changing method

A technology of surface oil and replacement method, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of interface mismatch, inability to use various electrical, electronic parts, mechanical parts and auto parts, low production capacity, etc. To achieve the effect of improving the performance of the characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

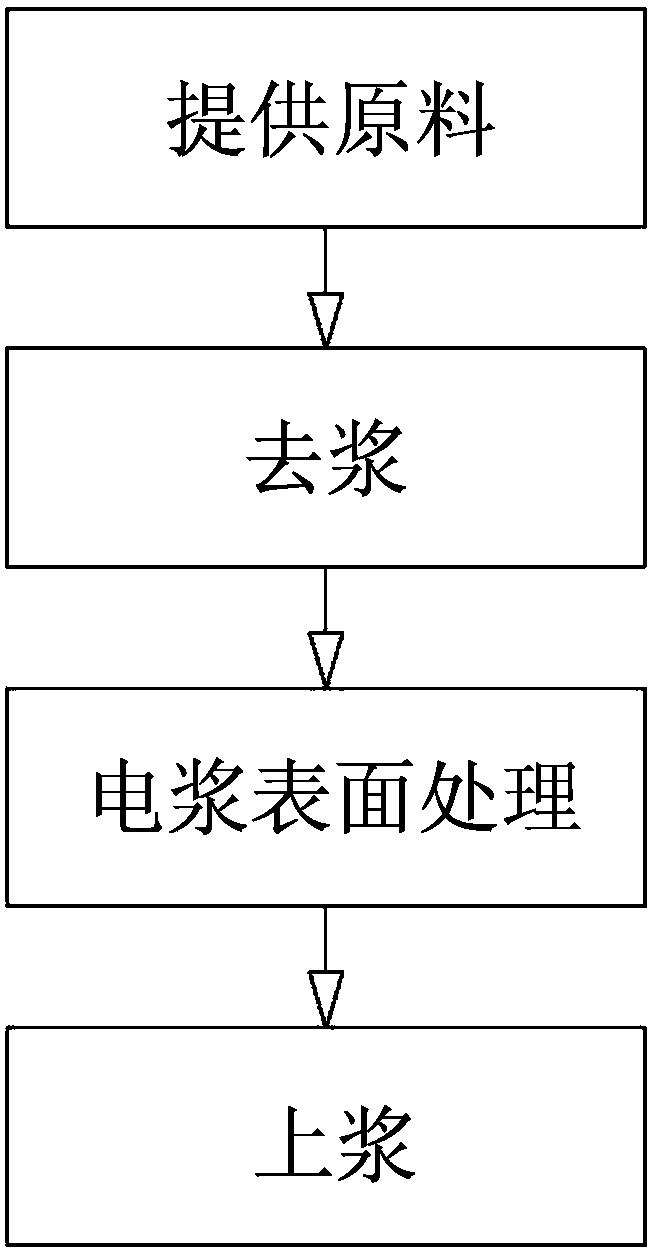

[0037] The present invention mainly provides a carbon fiber surface oil agent replacement method that can effectively replace the oil agent on the carbon fiber surface, such as figure 1 As shown, the carbon fiber surface oil agent replacement method of the present invention basically includes the following steps in order: a step of providing raw materials, a step of desizing, a step of plasma surface treatment, and a step of sizing; Figure 2 to Figure 5 Further descriptions of possible implementation forms of each step are as follows.

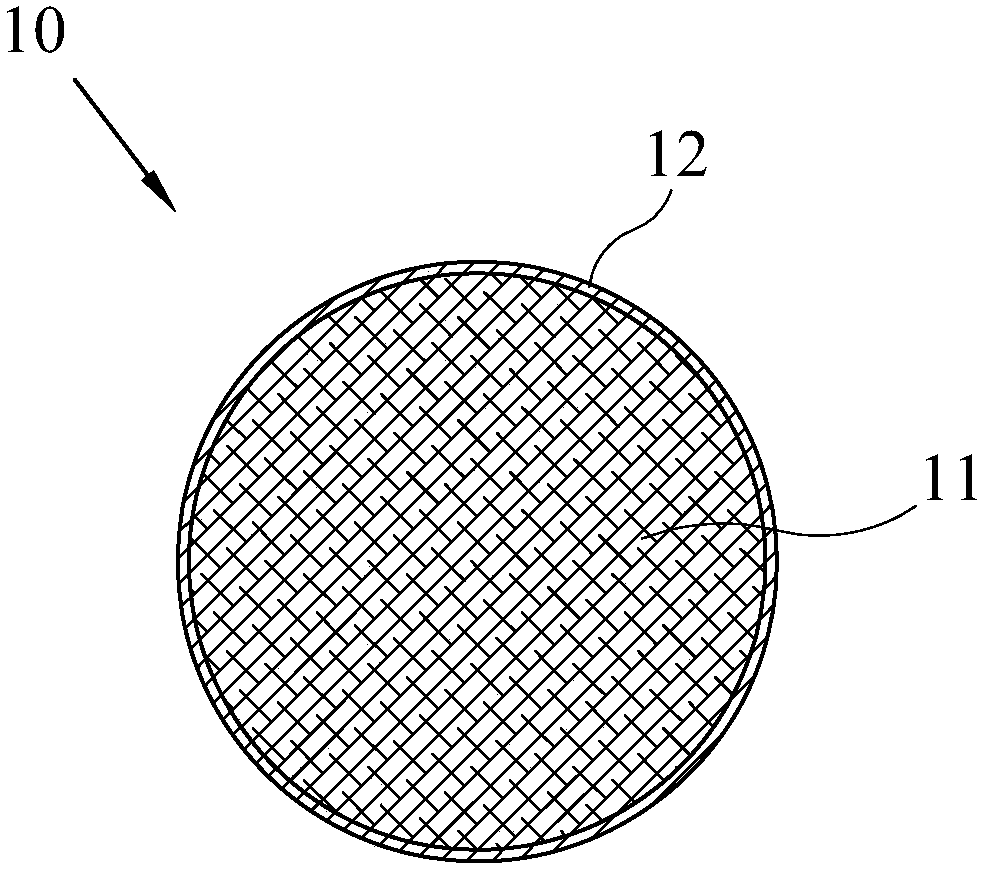

[0038] In this step of providing raw materials, mainly provide a carbon fiber raw material 10 covered with a first oil agent 12 on the surface of a carbon fiber 11; said carbon fiber e is made of rayon, polyvinyl alcohol, vinylidene chloride, polyacrylonitrile (polyacrylonitrile, PAN), pitch (pitch) and other precursor fibers bundled into carbon fiber precursor fiber bundles obtained by calcining; during implementation, the first oil agent 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com