A kind of co@c/biomass catalyst and its preparation method and application

A biomass and catalyst technology, applied in the field of Co@C/biomass catalyst and its preparation, can solve the problem of low catalytic efficiency of the catalyst, and achieve the effects of low cost, uniform distribution and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

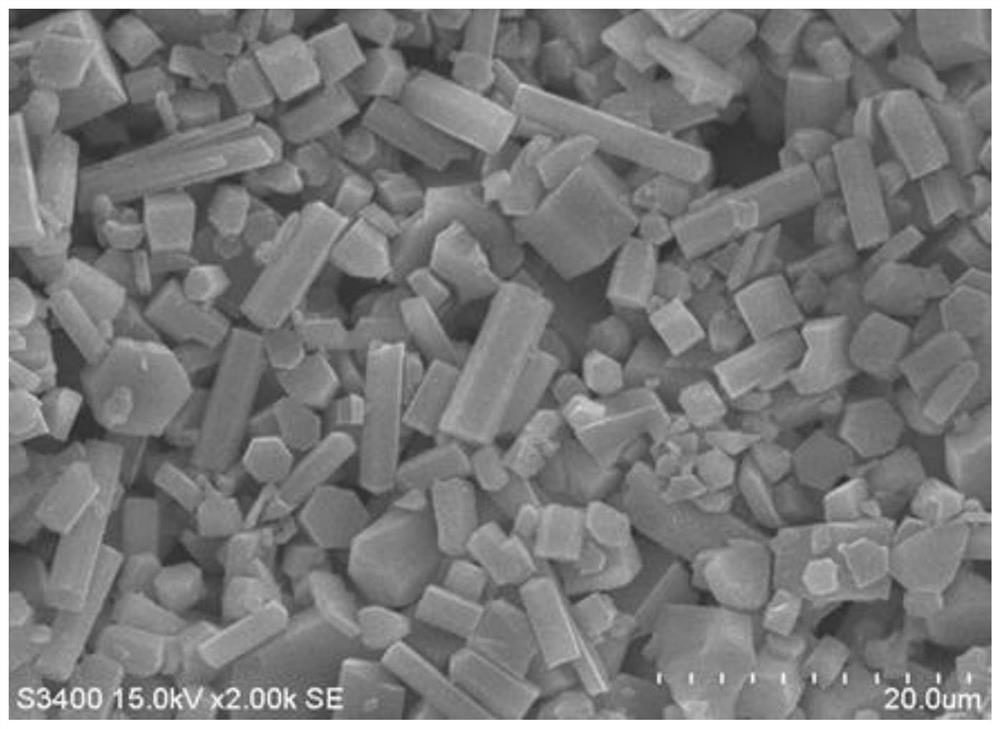

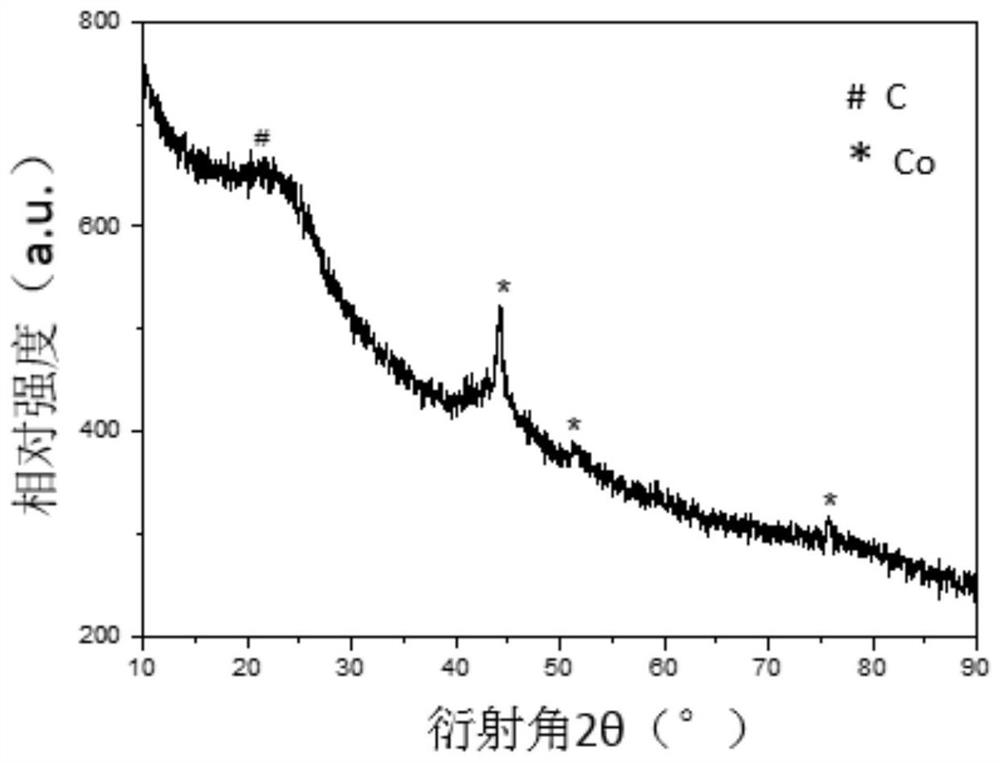

Image

Examples

Embodiment 1

[0031] (1) Take 1.5g cubic wood block, reflux it with 50mL nitric acid solution at 80°C for 12 hours, then wash the block repeatedly with deionized water for 5 times under boiling conditions, dry it at room temperature, and seal it. stand-by;

[0032] (2) Pour 45mL of DMF, 3mL of methanol and 3mL of deionized water into a flask, weigh 0.48g (1.65mmol) of cobalt nitrate hexahydrate and 0.0989g (0.5mmol) of 2,5-dihydroxyterephthalene Formic acid was placed in a flask together and stirred evenly to obtain a precursor solution of Co-MOF-74;

[0033] (3) Put the cubic wooden blocks to be used in step (1) into a three-necked flask, vacuum seal, extract the precursor solution of Co-MOF-74 with a needle tube, pour it into a three-necked flask, vacuum seal and impregnate for 5 hours, Then put the flask into a vacuum drying oven at 80°C for constant temperature reaction for 12 hours. After the reaction, the flask is cooled to room temperature, and the wooden block is taken out, and dri...

Embodiment 2

[0040] (1) Take 2g cube wood block, reflux it with 50mL nitric acid solution at 120°C for 1 hour, then wash the block repeatedly with deionized water for 5 times under boiling conditions, dry it at room temperature, and seal it until use;

[0041] (2) Pour 17mL of DMF, 17mL of methanol and 17mL of deionized water into a flask, weigh 0.145g (0.5mmol) of cobalt nitrate hexahydrate and 0.0989g (0.5mmol) of 2,5-dihydroxyterephthalene Formic acid was placed in a flask together and stirred evenly to obtain a precursor solution of Co-MOF-74;

[0042] (3) Put the cubic wood blocks to be used in step (1) into a three-necked flask, vacuum seal, extract the precursor solution of Co-MOF-74 with a needle tube, pour it into a three-necked flask, vacuum seal and impregnate for 3 hours, Then put the flask into a vacuum drying oven at 60°C for constant temperature reaction for 36 hours. After the reaction, the flask is cooled to room temperature, and the wooden block is taken out, and dried at ...

Embodiment 3

[0046] (1) Take 1g of cubic wood block, reflux it with 50mL hydrogen peroxide at 50°C for 36 hours, then wash the block repeatedly with deionized water for 5 times under boiling conditions, dry it at room temperature, and seal it for use ;

[0047] (2) Measure 100mL of DMF, 5mL of methanol and 5mL of deionized water into a flask, respectively weigh 1.4527g (5mmol) of cobalt nitrate hexahydrate and 0.0989g (0.5mmol) of 2,5-dihydroxyterephthalic acid , put them together in a flask, and stir evenly to prepare a Co-MOF-74 precursor solution;

[0048] (3) Put the cubic wood blocks to be used in step (1) into a three-necked flask, vacuum seal, extract the precursor solution of Co-MOF-74 with a needle tube, pour it into a three-necked flask, vacuum seal and impregnate for 10 hours, Then put the flask into a vacuum drying oven at 100°C for a constant temperature reaction for 5 hours. After the reaction, the flask was cooled to room temperature, and the wooden block was taken out, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com