In-situ preparation method of self-heating flexible wearable nanofiber material

A nanofiber and in-situ preparation technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of not realizing the integration of multiple functions, unstable functional substances, etc., and achieve excellent temperature and humidity sensing functions and self-heating effect, high heat generation stability, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An in-situ preparation method of a self-heating flexible wearable nanofiber material provided by an embodiment of the present invention includes the following steps:

[0029] Step S1: Silk Cocoons with 1% NaHCO 3 Boil for 30 minutes, then dissolve it in a 5% LiBr aqueous solution, stir continuously for 1 hour, and then dialyze it in deionized water for 3 days to obtain the silk precursor to be modified;

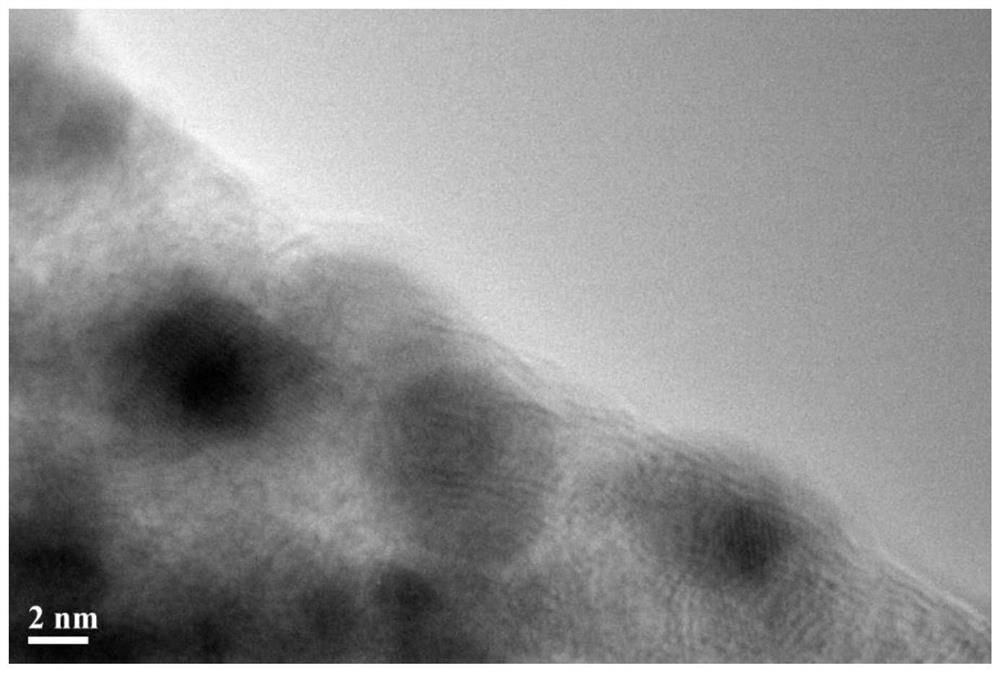

[0030] Step S2: heating and stirring the graphene in a mixed solution of concentrated sulfuric acid, concentrated nitric acid and potassium permanganate to obtain a uniformly dispersed modified graphene solution;

[0031] Step S3: mixing the modified graphene solution and the silk precursor to be modified, the graphene:silk precursor mass ratio after mixing is 20:80, and then ultrasonically dispersing to obtain a graphene-modified silk fiber mixed solution;

[0032] Step S4: adding 0.2% CuCl to the obtained graphene-modified silk fiber solution 2 , and then, the NaOH...

Embodiment 2

[0035] An in-situ preparation method of a self-heating flexible wearable nanofiber material provided by an embodiment of the present invention includes the following steps:

[0036] Step S1: Silk Cocoon with 0.5% NaHCO 3 Boiled for 30 minutes, then dissolved in 3% LiBr aqueous solution, stirred continuously for 1 hour, and then dialyzed in deionized water for 3 days to obtain the silk precursor to be modified;

[0037] Step S2: heating and stirring the carbon nanotubes in a mixed solution of concentrated sulfuric acid, concentrated nitric acid and potassium permanganate to obtain a uniformly dispersed modified carbon nanotube solution;

[0038] Step S3: mixing the modified carbon nanotube solution and the silk precursor to be modified, the carbon nanotube: silk precursor mass ratio after mixing is 20:80, and then ultrasonically dispersing to obtain a carbon nanotube-modified silk fiber mixed solution;

[0039] Step S4: adding 0.2% CuCl to the obtained carbon nanotube-modified s...

Embodiment 3

[0042] An in-situ preparation method of a self-heating flexible wearable nanofiber material provided by an embodiment of the present invention includes the following steps:

[0043] Step S1: Silk cocoon with 0.5% NaHCO 3 Boil for 30 minutes, then dissolve it in a 5% LiBr aqueous solution, stir continuously for 1 hour, and then dialyze it in deionized water for 3 days to obtain the silk precursor to be modified;

[0044] Step S2: heating and stirring the graphene in a mixed solution of concentrated sulfuric acid and concentrated nitric acid to obtain a uniformly dispersed modified graphene solution;

[0045] Step S3: mixing the modified graphene solution and the silk precursor to be modified, the graphene:silk precursor mass ratio after mixing is 10:90, and then ultrasonically dispersing to obtain a graphene-modified silk fiber mixed solution;

[0046] Step S4: adding 0.5% CuCl to the obtained graphene-modified silk fiber solution 2 Then, the NaOH aqueous solution with 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com