Carbon nanotube fiber hybrid fabric, preparation method thereof and reinforced composite material

A carbon nanotube fiber and reinforced composite material technology, applied in the field of fiber materials, can solve the problems affecting the use of bulletproof products, irreversible deformation, high temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

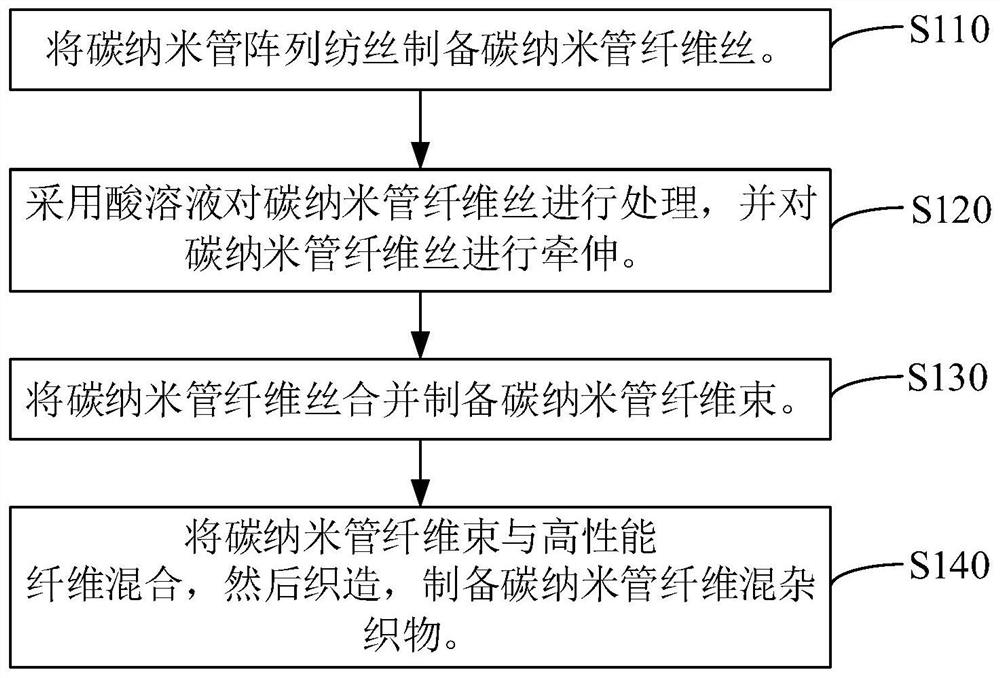

[0034] see figure 1 , the preparation method of the carbon nanotube fiber hybrid fabric of an embodiment, comprises the steps:

[0035] Step S110: Spinning the carbon nanotube array to prepare carbon nanotube filaments.

[0036] Wherein, in the carbon nanotube array, the length of the carbon nanotubes is 100 μm˜1000 μm, and the diameter is 6 nm˜15 nm. Further, the length of the carbon nanotubes is 300 μm˜600 μm. The length and diameter of the carbon nanotubes in the carbon nanotube array are appropriate, so that the strength of the prepared carbon nanotube fibers is relatively high.

[0037] Specifically, step S110 includes: pulling out a film with a width of 0.1 cm to 20 cm from the carbon nanotube array, twisting and spinning it into filaments, and preparing carbon nanotube fiber filaments. Further, the width of the drawn film is 0.1 cm to 5 cm. In one of the embodiments, the twist is 100tpm-15000tpm in the process of twisting and spinning into filaments. Further, the t...

Embodiment 1-1

[0068] The preparation process of the carbon nanotube fiber hybrid fabric of the present embodiment is as follows:

[0069] (1) Pull out a film with a width of 10 cm from a carbon nanotube array with a length of 500 μm and a diameter of 10 nm, and then twist and spin it with a twist of 2000 tpm to obtain carbon nanotube fiber filaments.

[0070] (2) Soak the carbon nanotube fibers obtained in step (1) in a nitric acid solution with a mass concentration of 20% for 30 minutes, and stretch the carbon nanotube fibers with a draft ratio of 1.06.

[0071] (3) Merge the 50 carbon nanotube fiber filaments treated in step (2) into a bundle of carbon nanotube fiber bundles.

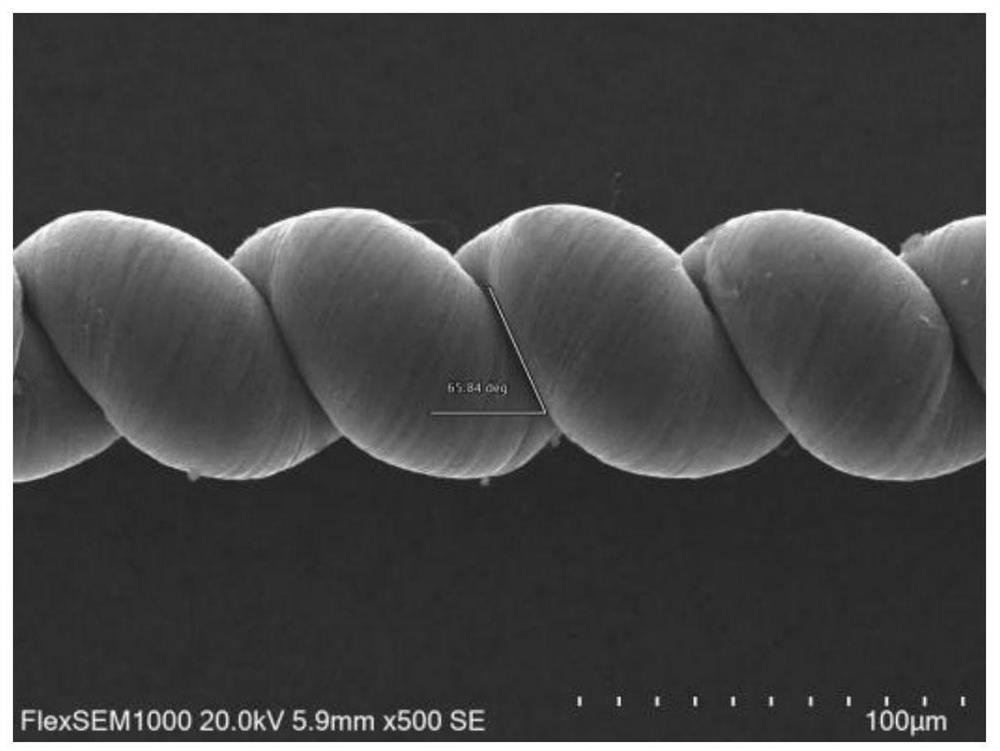

[0072] (4) The carbon nanotube fiber bundles treated in step (3) are mixed with the aramid fibers by a core wrapping method, the outer wrapping fibers are carbon nanotube fiber bundles, the inner core yarn is aramid fibers, and The volume ratio of carbon nanotube fiber bundles to aramid fibers is 1:5, and then wov...

Embodiment 1-2

[0074] The preparation process of the carbon nanotube fiber hybrid fabric of the present embodiment is as follows:

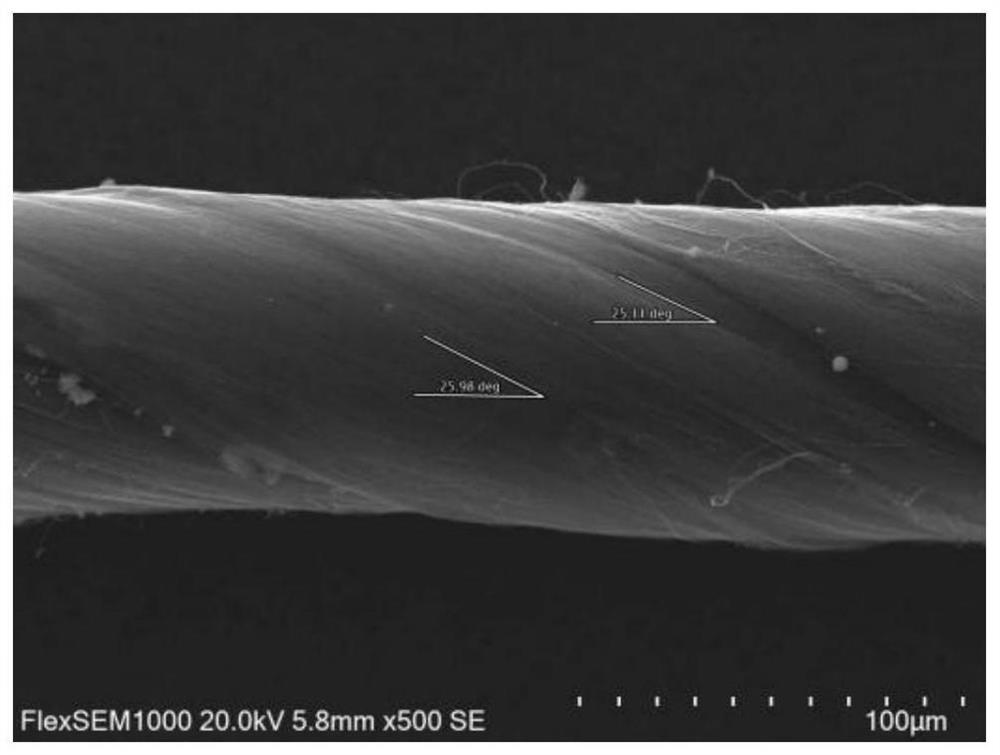

[0075] (1) Pull out a film with a width of 10 cm from a carbon nanotube array with a length of 500 μm and a diameter of 10 nm, twist and spin it with a twist of 2000 tpm to obtain carbon nanotube fiber filaments.

[0076] (2) Soak the carbon nanotube fibers obtained in step (1) in a nitric acid solution with a mass concentration of 20% for 30 minutes, and stretch the carbon nanotube fibers with a draft ratio of 1.06.

[0077] (3) Merge the 50 carbon nanotube fiber filaments treated in step (2) into a bundle of carbon nanotube fiber bundles.

[0078] (4) The carbon nanotube fiber bundles treated in step (3) are mixed with ultra-high molecular weight polyethylene fibers by a core-wrapping method, the outer wrapping fibers are carbon nanotube fibers, and the inner core yarn is ultra-high molecular weight Polyethylene fibers, and the volume ratio of carbon nanotube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com