Preparation method of natural-color Chinese pennisetum fiber water-absorption lining paper

A grass fiber, natural color technology, which is applied in cellulose raw material pulping, cellulose pulp post-processing, pulp beating/refining methods, etc., can solve the adverse effects of physical strength, absorbent bulk, softness and air permeability, The problems of high content of fine fiber and decreased pulping yield can reduce the probability of irritation and allergy, high antibacterial, antibacterial and antiallergic, and prevent or prevent inflammation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

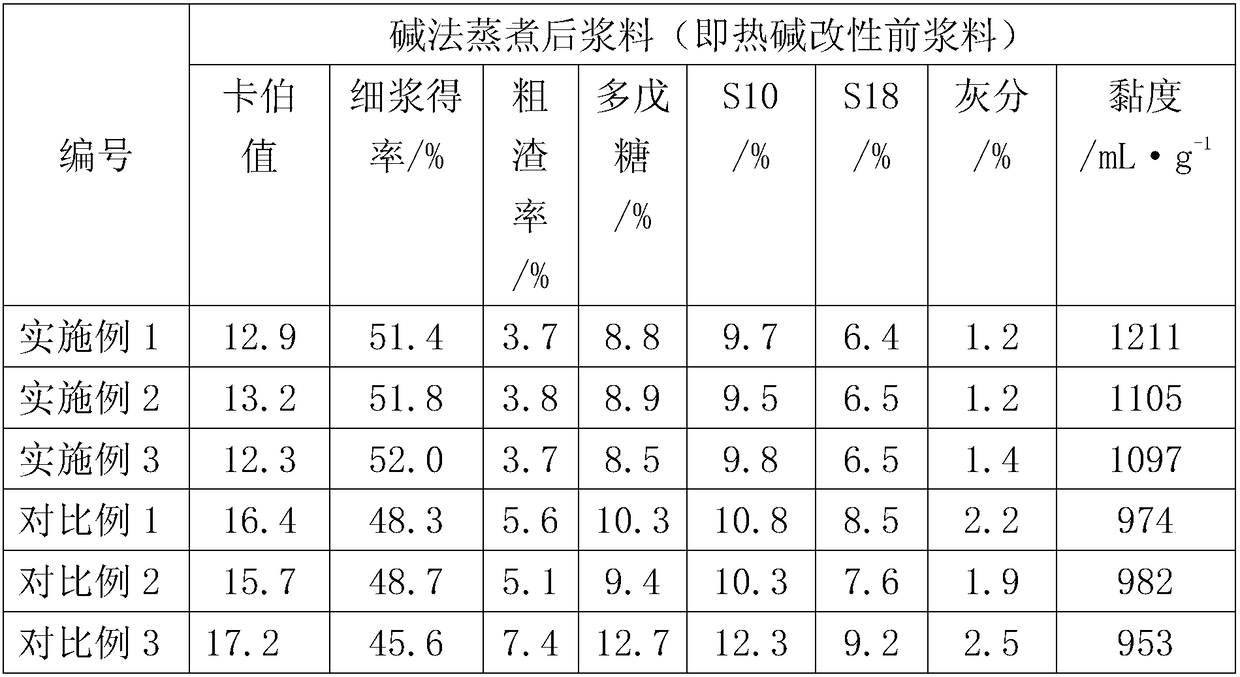

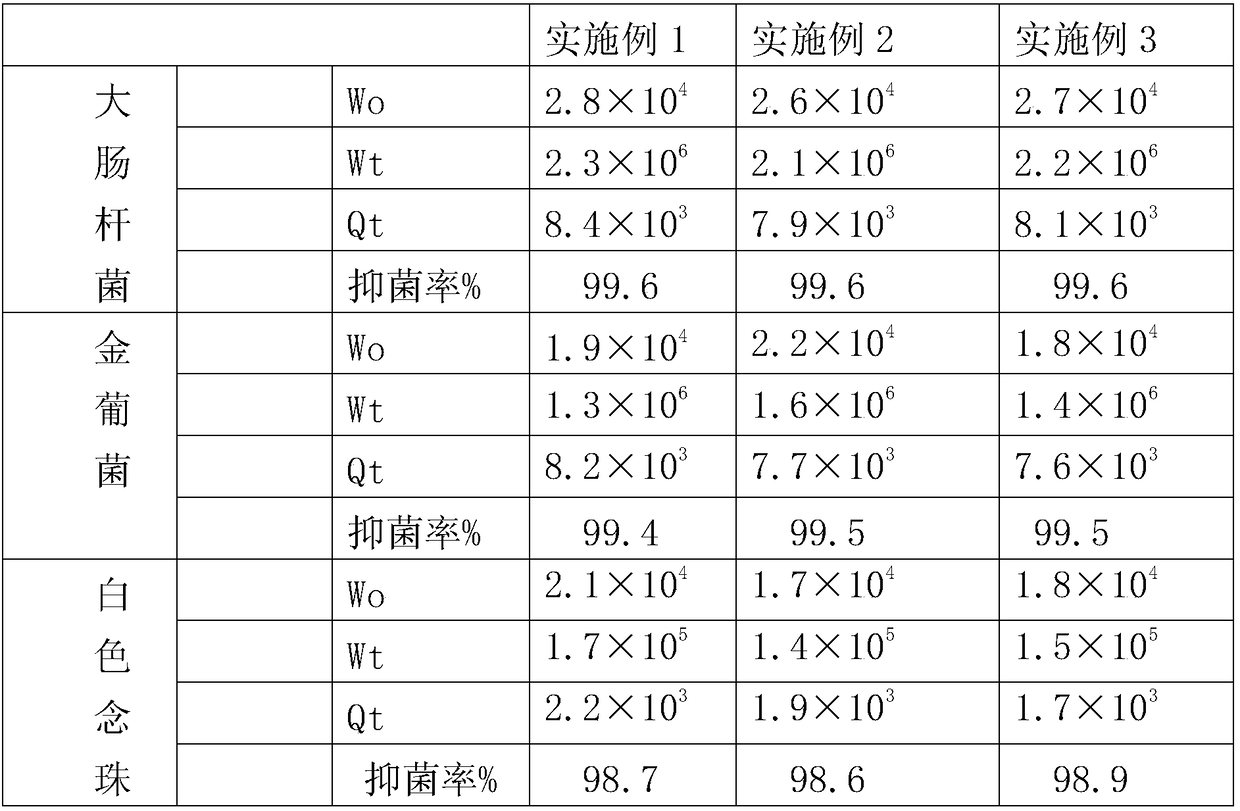

Examples

Embodiment 1

[0039] (1) Pre-pressing: the honeysuckle stalks from which the tips, roots and leaves have been removed are sent to a press for pressing, the pre-pressing pressure is 8 MPa, the pressing time is 10 minutes, and the temperature is normal temperature.

[0040] (2) Screening and dedusting section: Send the honeysuckle grass flakes that have been air-dried for 2 months into a vibrating roller dust collector to separate heavy and light flakes from qualified flakes. The air-dried flakes stay in the vibrating roller dust collector for 20 minutes.

[0041] (3) Pre-impregnation section: the pre-impregnation process is carried out by sending the screened and dedusted tablets into the digester. The residence time of the tablet in the impregnation section is 90min, the temperature is 80°C, the amount of sodium hydroxide is 5% relative to the mass of the absolute dry raw material, and the liquid ratio is 1:5.

[0042] (4) Alkaline cooking: After the pre-impregnation, add alkaline substanc...

Embodiment 2

[0053] (1) Pre-pressing: the honeysuckle stalks from which the tips, roots and leaves have been removed are sent to an extruder for pressing, the pre-pressing pressure is 20 MPa, the pressing time is 2 minutes, and the temperature is normal temperature.

[0054] (2) Screening and dedusting section: the honeysuckle grass flakes that have been air-dried for 12 months are sent to the vibrating roller dust collector to separate heavy and light flakes from qualified flakes. The residence time of the air-dried tablet in the vibrating roller dust collector is 10 minutes.

[0055] (3) Pre-impregnation section: the pre-impregnation process is carried out by sending the screened and dedusted tablets into the digester. The residence time of the tablet in the impregnation section is 10min, the temperature is 95°C, the amount of sodium hydroxide is 10% relative to the mass of the absolute dry raw material, and the liquid ratio is 1:2.

[0056] (4) Alkaline cooking: After the pre-impregnat...

Embodiment 3

[0064] (1) Pre-pressing: the honeysuckle stalks from which the tips, roots and leaves have been removed are sent to an extruder for pressing. The pre-pressing pressure is 16 MPa, the pressing time is 6 minutes, and the temperature is normal temperature.

[0065] (2) Screening and dedusting section: Send the honeysuckle flakes that have been air-dried for 6 months into a vibrating roller dust collector to separate heavy and light flakes from qualified flakes. The air-dried flakes stay in the vibrating roller dust collector for 40 minutes.

[0066] (3) Pre-impregnation section: the pre-impregnation process is carried out by sending the screened and dedusted tablets into the digester. The residence time of the tablet in the impregnation section is 120min, the temperature is 20°C, the amount of sodium hydroxide is 1%, and the liquid ratio is 1:6 relative to the mass of the absolute dry raw material.

[0067] (4) Alkaline cooking: After the pre-impregnation, add alkaline substance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com