A liquid cooling module for lithium ion power battery

A power battery and battery module technology, applied in battery pack components, batteries, secondary batteries, etc., can solve the problems of decreasing volume specific energy density, increasing the temperature rise of battery cells, and large temperature difference between modules, etc. Mass energy density, the effect of reducing the temperature difference between modules, and reducing the temperature difference between cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

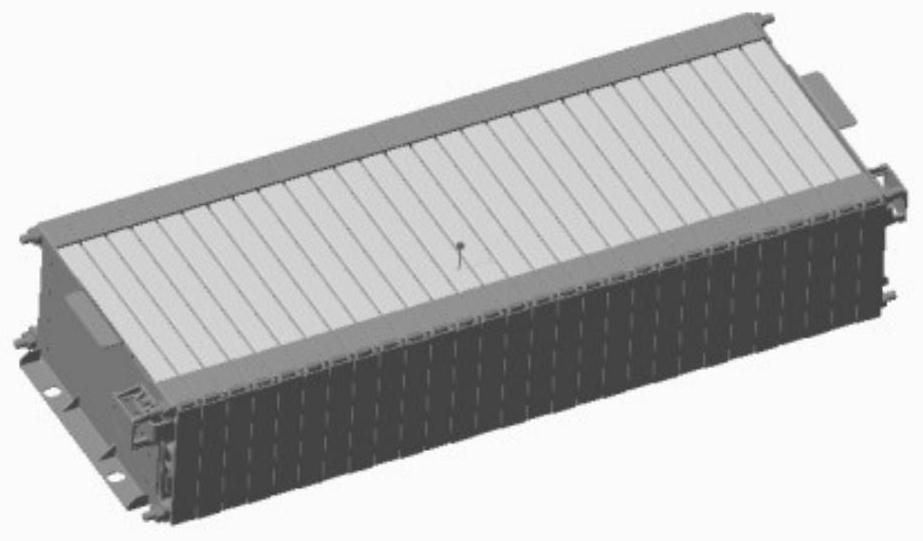

[0051] see Figure 6 and Figure 7 , a lithium-ion power battery liquid-cooled module, the battery module is assembled from a plurality of battery modules 2, the upper and lower housing fixing nuts 304 are fixed, and the upper and lower series copper bars 305 and the left and right series copper bars 306 are arranged. The upper surface and the lower surface of the battery module are provided with slots for placing liquid-cooled flat tubes; the slots are parallel to the length direction of the battery module; the lithium-ion power battery liquid cooling module includes back and forth arrangements The liquid-cooled flat tube extends along the length direction of the battery module, bends at the end of the battery module, and passes through the liquid-cooled flat tube 303 between adjacent battery modules. The battery module includes a module metal lower case 301 and a module metal upper case 302. Both the upper case and the lower case are made of heat-conducting plastic and are ...

Embodiment 2

[0058] A lithium-ion power battery liquid cooling module, the battery module is assembled from a plurality of battery modules, the upper surface and the lower surface of the battery module are provided with slots for placing liquid-cooled flat tubes; the slots are parallel to the in the length direction of the battery module; the lithium-ion power battery liquid cooling module includes liquid-cooled flat tubes arranged back and forth, and the liquid-cooled flat tubes extend along the length of the battery module and bend at the end of the battery module , each adjacent battery module passes through the liquid-cooled flat tube. The battery module includes an upper case and a lower case, both of which are made of heat-conducting plastic, and both of the upper case and the lower case are provided with card slots. Thermal pads are provided between the upper case and its adjacent pouch battery cells, and between the lower case and its adjacent pouch battery cells.

[0059] This em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com