Preparation method of high-dispersed transition metal nanoparticle-supported hierarchical pore zeolite aggregate

A technology of transition metals and nanoparticles, applied in the direction of nanotechnology, nanotechnology, non-metallic elements, etc., can solve the problems of affecting the activity of transition metal-supported catalysts, cumbersome preparation process, unevenness, etc., and achieves significant prospects for industrialization and application. The effect of simple preparation steps and easy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 0.6 g NiSO 4 and 2.2 g Al 2 (SO 4 ) 3 18H 2 O was dissolved in 25 ml of pure water, stirred and clarified, and added dropwise to 28 gNa 2 SiO 3 9H 2 In 20 ml aqueous solution of O, add 2 ml NH 3 ·H 2 O (concentration of 1 M) was used to adjust the alkalinity, and stirred for 23 minutes to obtain a nickel-silicon-alumina sol-gel solution, and then 0.7 g (13wt%) of silicate-1 seed solution was added dropwise to the above-prepared nickel-silicon-alumina Stir in the sol-gel solution for 30 minutes to obtain the precursor solution. The precursor solution is subjected to hydrothermal crystallization reaction at 150°C for 20 hours. After the reaction is completed, it is washed and dried, and the obtained product is highly dispersed Ni-ZSM-5 nanometer Zeolite aggregate catalyst material.

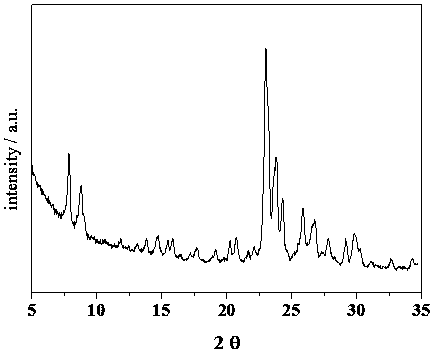

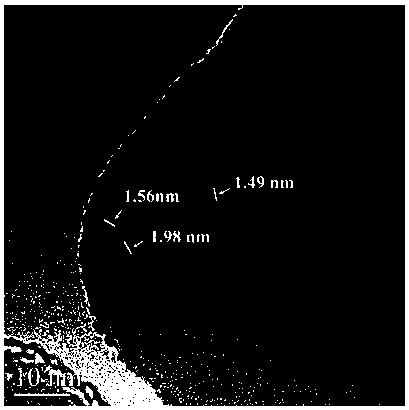

[0014] See attached figure 1 , the XRD spectrum of the obtained product Ni-ZSM-5 sample is consistent with the characteristic peaks of the standard MFI molecular sieve, indicating t...

Embodiment 2

[0017]0.4 g CuCl 2 ·6H 2 O and 1.1 g Al 2 (SO 4 ) 3 18H 2 O was dissolved in 25 ml pure water, stirred and clarified, then added dropwise to 28 g Na 2 SiO 3 9H 2 In 25ml aqueous solution of O, add 2.2ml NH 3 ·H 2 O (concentration of 1 M) was used to adjust the alkalinity, and stirred for 25 minutes to obtain a copper-silicon-alumina sol-gel solution, and then 0.5 g (13wt%) ß-zeolite zeolite seed solution was added dropwise to the above-prepared nickel-silicon-alumina The precursor solution was obtained by stirring in the sol-gel solution for 25 minutes, and the precursor solution was subjected to hydrothermal crystallization reaction at 170 °C for 26 hours. After the reaction was completed, it was washed and dried, and the obtained product was highly dispersed Cu-ß-zeolite nanometer Zeolite aggregate catalyst material.

Embodiment 3

[0019] 0.5 g CoCl 2 · 6H 2 O and 0.67 g Al2(SO 4 ) 3 18H 2 O was dissolved in 25 ml of pure water, stirred and clarified and added dropwise to 27 g of Na 2 SiO 3 9H 2 In 23ml aqueous solution of O, add 2.1ml NH 3 ·H 2 O (concentration of 1 M) was used to adjust the alkalinity, and stirred for 20 minutes to obtain a cobalt-silicon-alumina sol-gel solution, and then 0.4 g (13wt%) silicate-2 zeolite seed solution was added dropwise to the cobalt-silicon-alumina sol-gel solution prepared above The precursor solution was obtained by stirring in the sol-gel solution for 30 minutes, and the precursor solution was hydrothermally crystallized at 150°C for 20 hours. After the reaction was completed, it was washed and dried, and the obtained product was highly dispersed Co-ZSM-11 nanometer Zeolite aggregate catalyst material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com