A butt welding tool for inner and outer fork assembly

A welding tooling and assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased logistics time, low work efficiency, large workshop space, etc., and achieve high fixing accuracy and reduce equipment. The effect of clipping time and reducing logistics time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

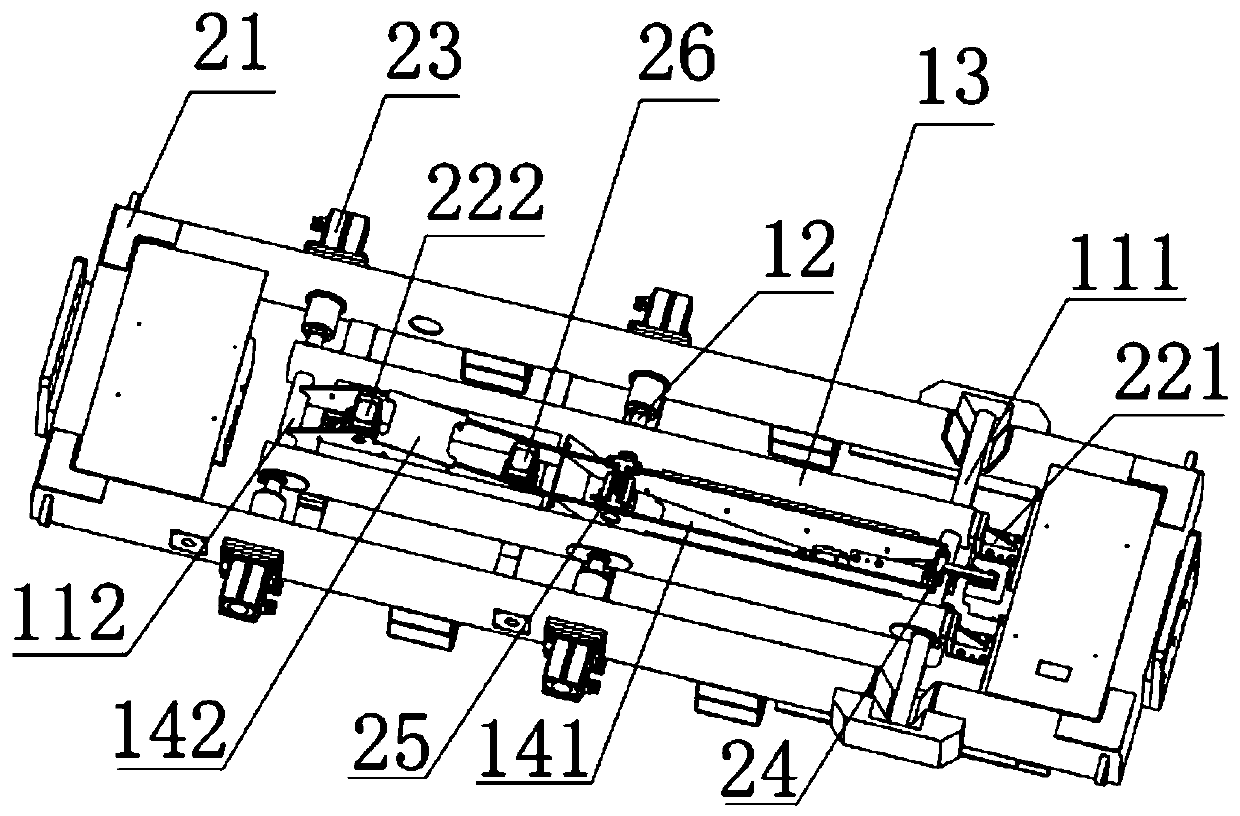

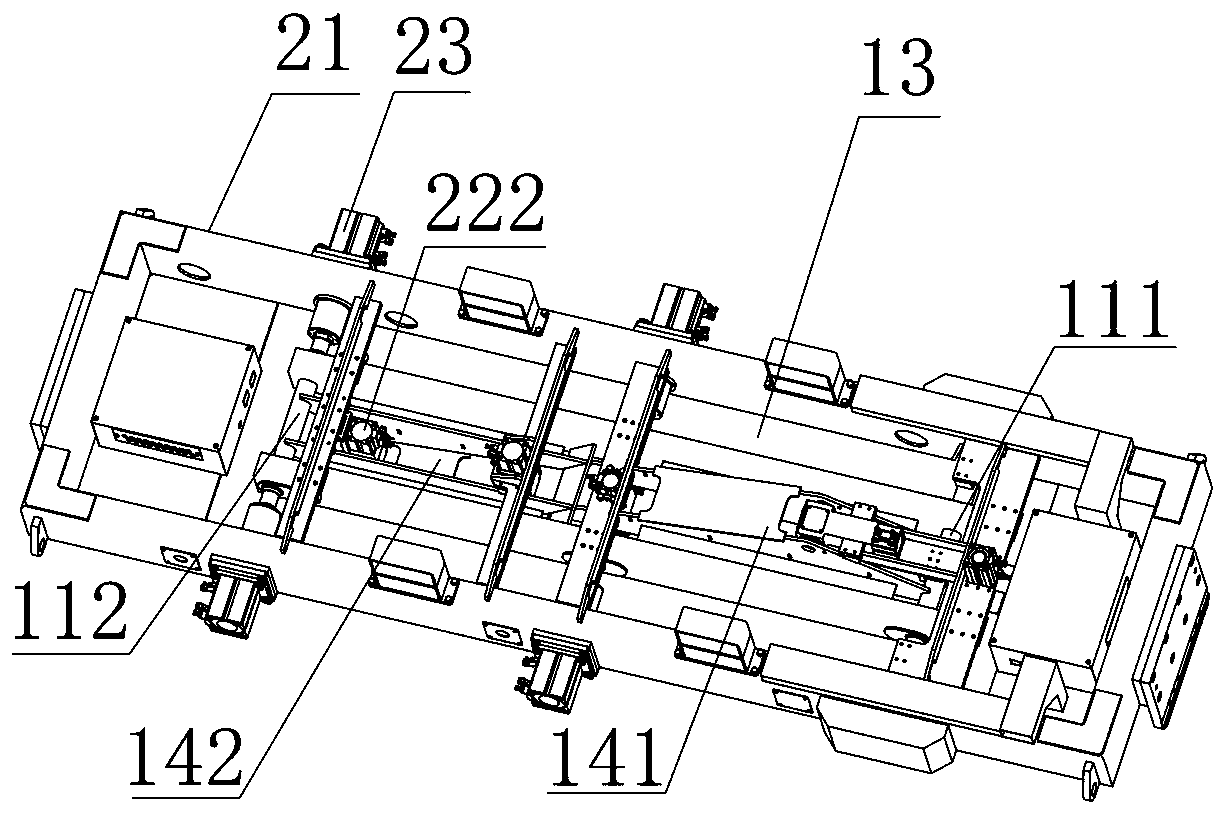

[0025] An inner and outer fork assembly butt welding tool in this embodiment, the inner and outer fork assembly includes inner and outer fork parts and a cylinder support, and the inner and outer fork parts include two fork rods 13, extended long sleeves 111, and ordinary long sleeves 112. Two short shaft sleeves 12, the head, middle and tail of the fork rods 13 are provided with connection holes and the two fork rods 13 are arranged in parallel, and the extended long shaft sleeves 111 are connected through the heads of the two fork rods 13 Ordinary long shaft sleeves 112 pass through the tail connection holes of the two fork rods 13, and the two short shaft sleeves 12 pass through the middle connection holes of the two fork rods 13 respectively; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com