A longitudinally reinforced cross-laminated timber and its manufacturing method

A glulam, longitudinal technology, applied in the direction of manufacturing tools, wood layered products, chemical instruments and methods, etc., can solve the problems that the bearing capacity and bending strength cannot meet the construction requirements of large-span projects, and improve production efficiency , The process is simple, the effect of reducing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

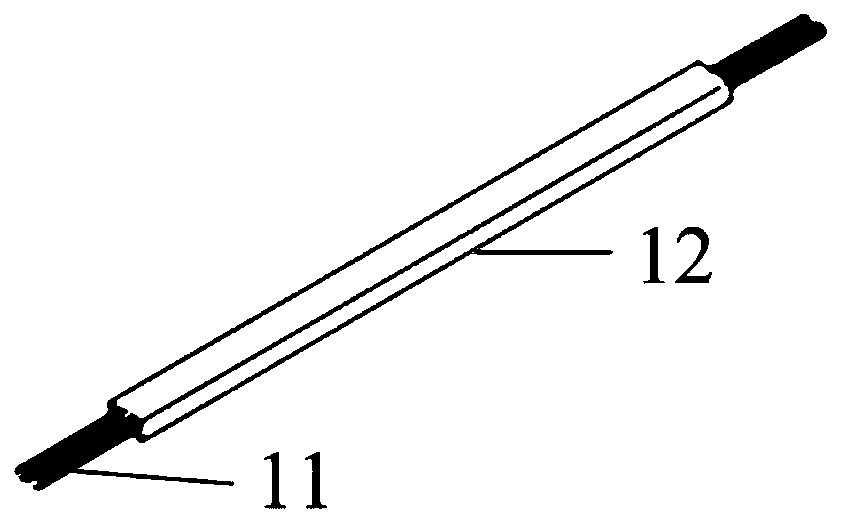

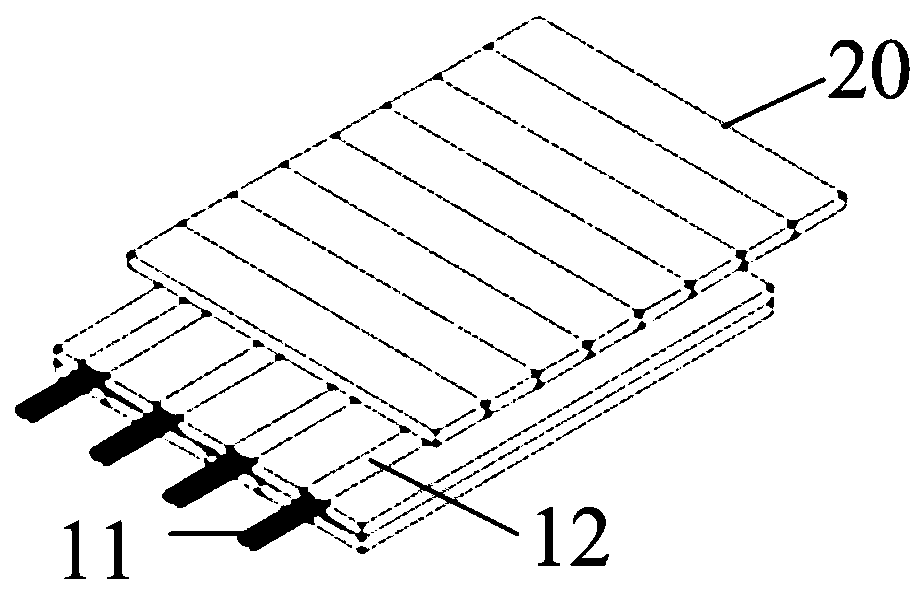

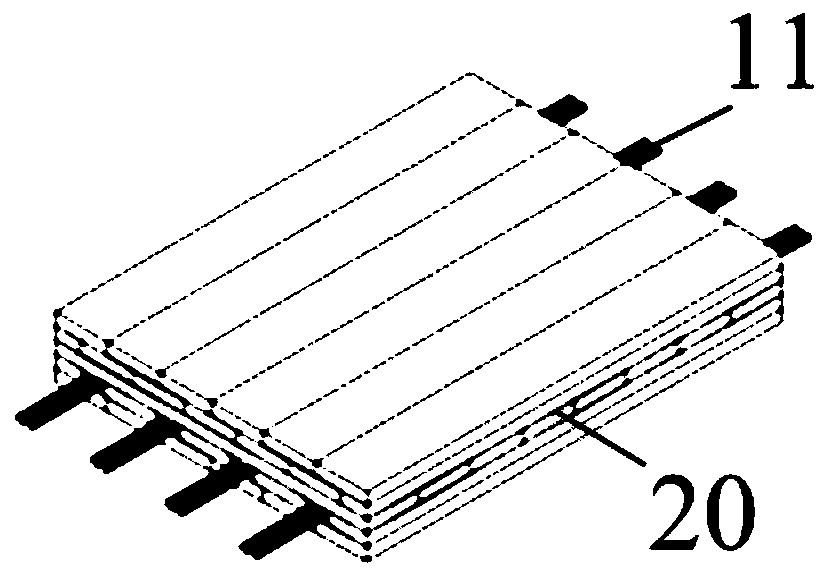

[0031] Such as Figure 1 to Figure 4 , a longitudinally reinforced cross-glued wood, comprising sawn timber 20, hollow particleboard 12 and steel bar 11, the steel bar 11 is arranged through the hollow particleboard 12 to form a reinforcing body, and the sawn timber 20 is assembled vertically and transversely to form an orthogonal glue Wood, the reinforcing body is placed in the longitudinal direction of the cross-laminated wood and formed together with the sawn timber 20 to form a longitudinally reinforced cross-laminated wood 30 .

[0032] Specifically, in order to overcome the shortcomings of the existing cross-glued wood technology, the steel bar 11 is glued and implanted into the hole of the hollow particle board 12, and the steel bar 11 is penetrated through the hollow particle board 12 to form a reinforcing body according to the length of the cross-glued wood member , the sawn timber 20 is assembled vertically and horizontally to form cross-glued wood, and then the rein...

Embodiment 2

[0038] Please continue to refer figure 1 and figure 2 , the present embodiment provides a method for manufacturing longitudinally reinforced cross-laminated timber of the present invention, the method of manufacturing comprising the following steps:

[0039] Step S1 gluing: Clean the surface of the steel bar 11, stick the prepared adhesive with a brush, evenly brush the surface of the treated steel bar and wipe it back and forth irregularly several times until the adhesive is applied to the steel bar The peripheral thickness of the surface is 1 mm to 2 mm; at the same time, the sawn timber 20 is planed and the surface is glued, and the glue is applied according to the type of adhesive selected and the glue parameters are determined to form a coating layer.

[0040]Step S2 Combination: insert the steel bar 11 coated with adhesive into the hole of the hollow particle board 12 matching the diameter of the steel bar, and obtain a reinforced body after curing; the length of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com