Environment-friendly high water content cohesive soil solidifying agent and using method thereof

A high water content, cohesive soil technology, applied in the field of geotechnical engineering, can solve the problems of low bearing capacity of high water content cohesive soil foundation, difficult to meet engineering requirements, large foundation settlement and deformation, etc. Simple construction and the effect of improving soil strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: an environment-friendly high water content cohesive soil curing agent and its use method, the curing agent includes (by weight percentage) polyacrylamide 10% to 30%, triisopropanolamine 5% to 15%, Sodium lignosulfonate 0.1%-1%, sodium bentonite 5%-20%, plant straw 10%-25%, and the balance is water;

[0029] The content of montmorillonite in the sodium bentonite is more than or equal to 85%;

[0030] The plant straw is at least one of rice straw, wheat straw, bamboo fiber and reed straw.

[0031] The using method of described environment-friendly type high water content cohesive soil solidifying agent comprises the following steps:

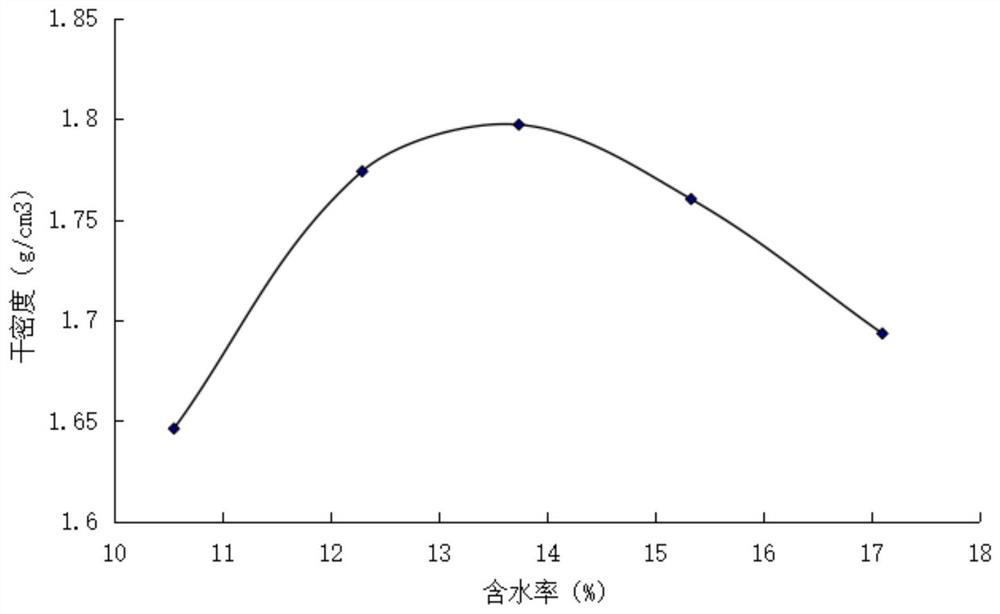

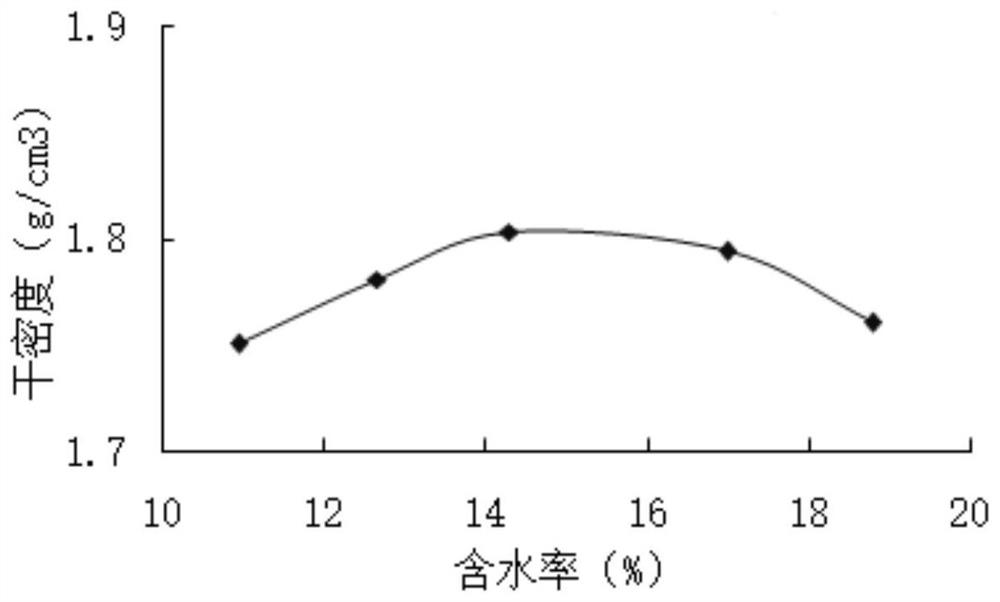

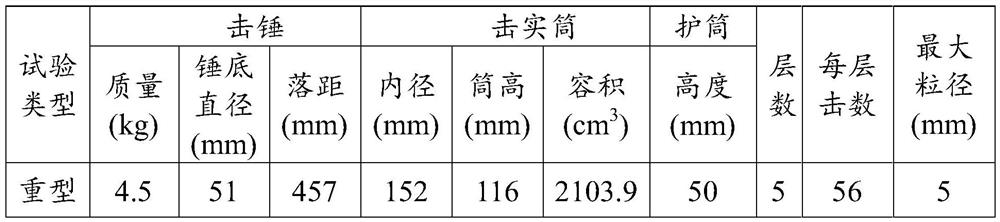

[0032] Step 1: The project site uses a soil moisture meter to measure the water content in the cohesive soil (the indoor drying method is used to measure the water content in the cohesive soil), and the optimal water content of the cohesive soil is detected by the compaction test, and then according to the formula α=m 钠质膨润土 / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com