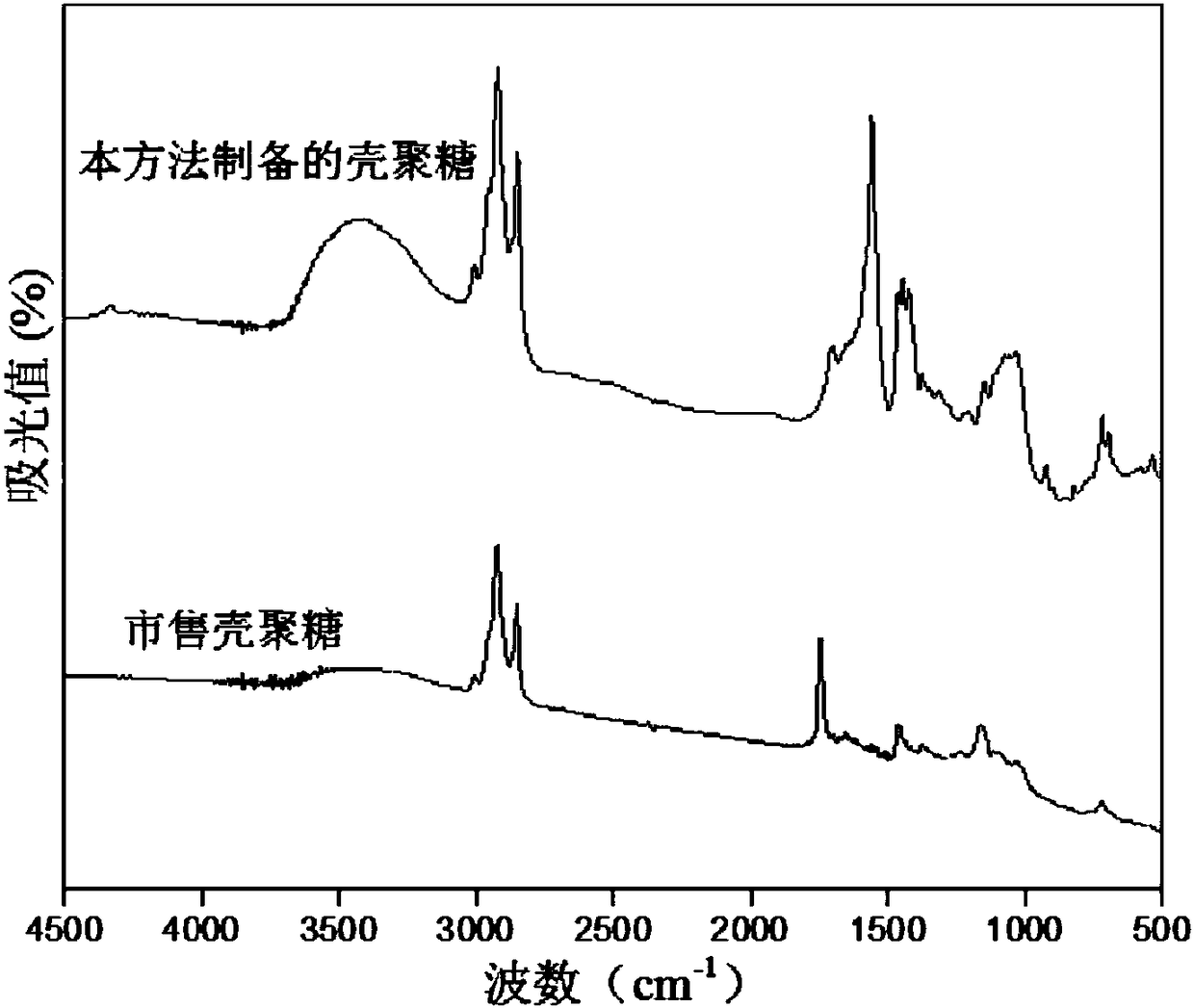

Method for ultrasonic assisted conversion of chitin into chitosan

An ultrasonic-assisted, chitin technology, applied in the field of chitosan, can solve the problems of poor effect of Ganoderma lucidum spore powder, numerous preparation steps, environmental pollution by waste liquid, etc., and achieve the effects of broadening the source, shortening the reaction time, and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

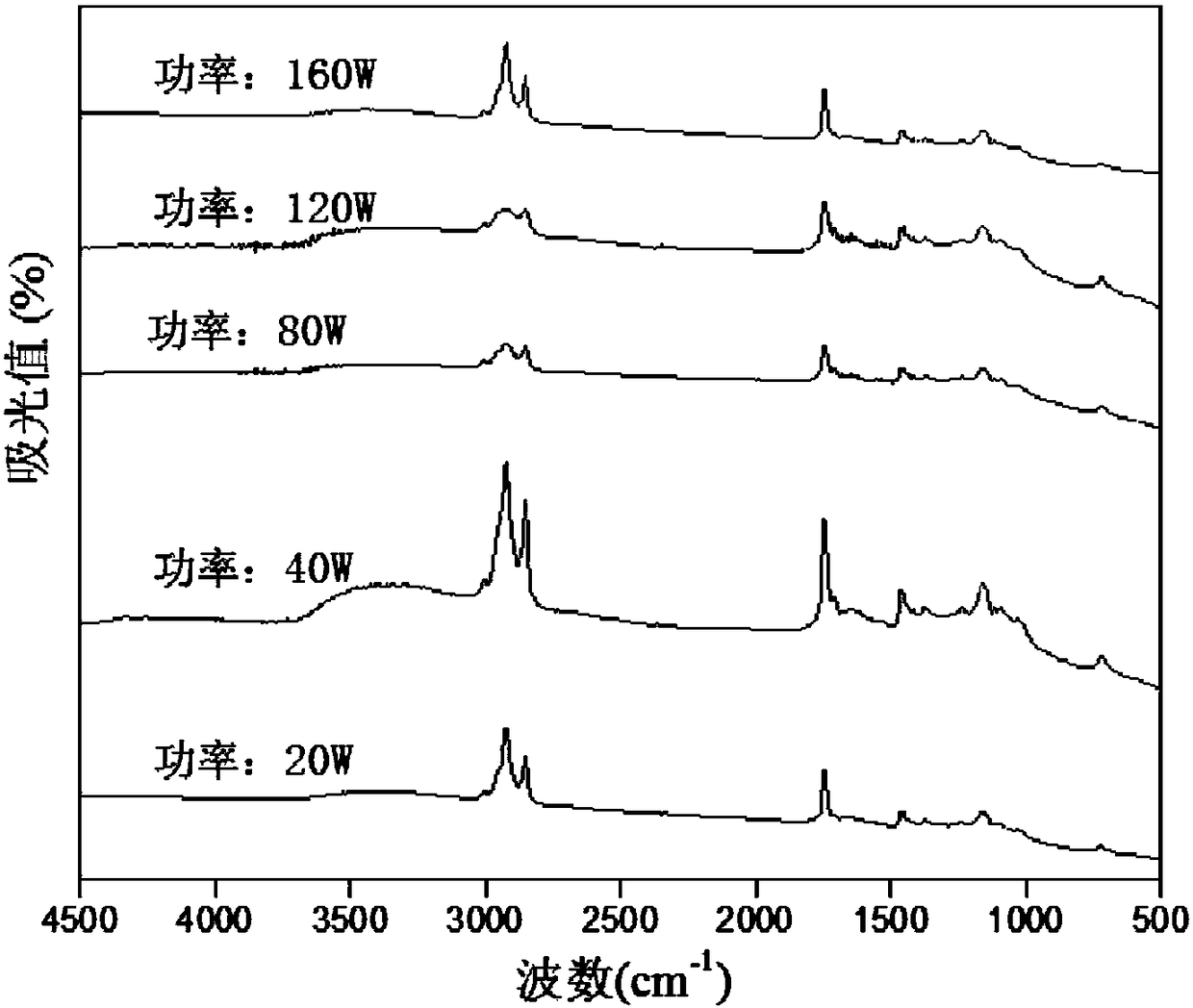

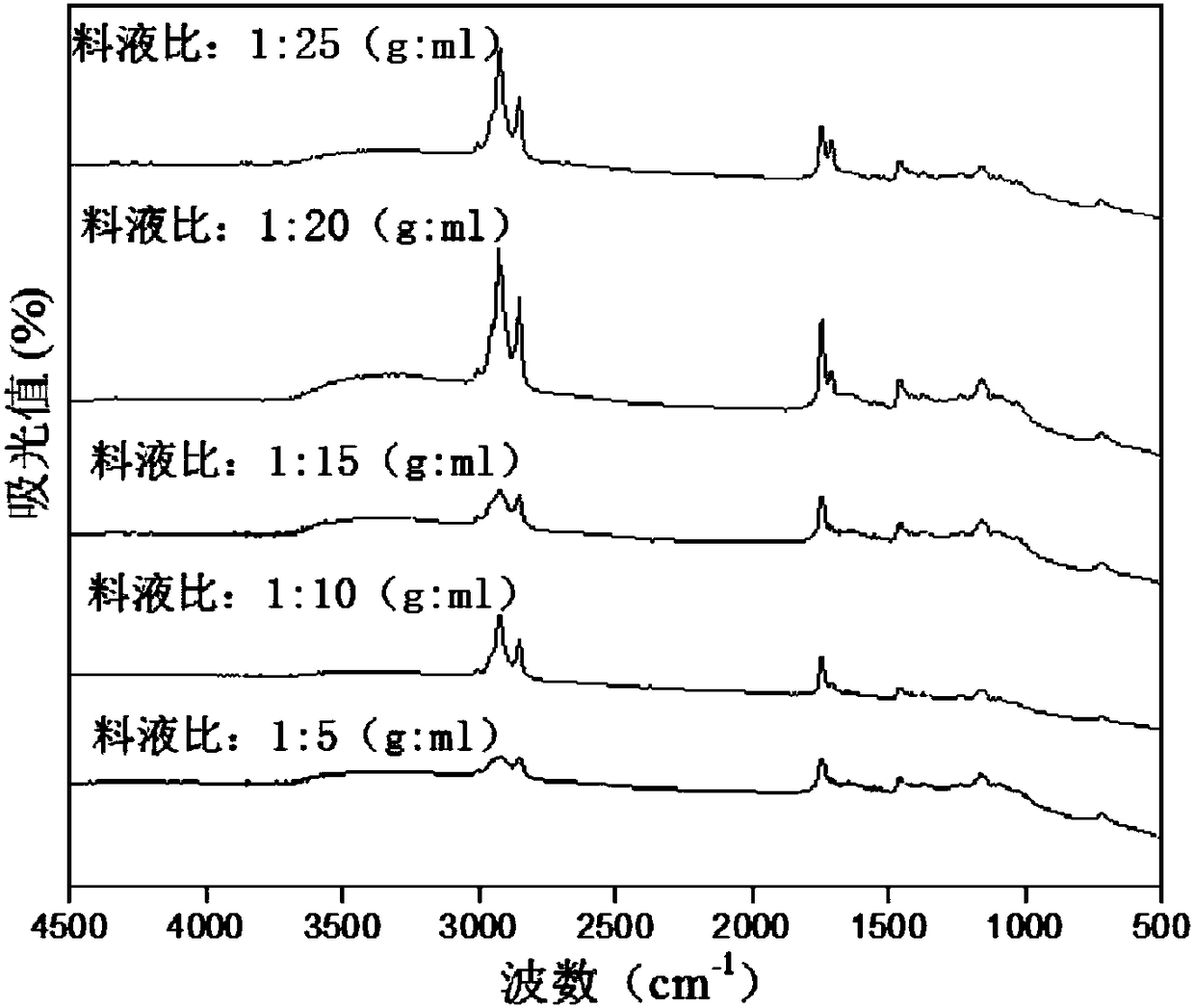

Embodiment 1

[0034] (1) Take 1 g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder according to the ratio of material to liquid 1:15 (g:ml), and extract Ganoderma lucidum polysaccharide once at 45°C with water bath ultrasonic (100W) and then use 7000rpm Centrifuge for 10 minutes to remove the supernatant to obtain the primary precipitate; add 95v / v% ethanol to the primary precipitate according to the ratio of material to liquid 1:15 (g:ml), and ultrasonicate at room temperature (25°C±1°C) for 1h to remove the three Terpenoids, and then centrifuged under the same centrifugation conditions to obtain the secondary precipitate; add deionized water to the secondary precipitate according to the ratio of solid to liquid 1:30 (g:ml), soak for 3 hours at 25°C to remove water-soluble protein, and After centrifugation under the same centrifugation conditions, the precipitate obtained three times was dried at 55°C to obtain crude chitin;

[0035] (2) Ta...

Embodiment 2

[0044](1) Take 1 g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder according to the ratio of material to liquid 1:25 (g:ml), and extract Ganoderma lucidum polysaccharide three times at 55°C with water bath ultrasonic (150W) and then use 10000rpm Centrifuge for 5 minutes to remove the supernatant to obtain the primary precipitate; add 95v / v% ethanol to the primary precipitate according to the ratio of material to liquid 1:25 (g:ml), and ultrasonicate for 2 hours at room temperature (25°C±1°C) to remove the three Terpenoids, and then centrifuged under the same centrifugation conditions to obtain the secondary precipitate; according to the ratio of solid to liquid 1:40 (g:ml), add deionized water to the secondary precipitate, soak at 35°C for 2h to remove water-soluble protein, and After the same centrifugation, the precipitate obtained three times was dried at 60°C to obtain crude chitin;

[0045] (2) Take 1g of crude chitin, ad...

Embodiment 3

[0050] (1) Take 1 g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder according to the ratio of material to liquid 1:30 (g:ml), and extract Ganoderma lucidum polysaccharide once at 65°C with water bath ultrasonic (200W) and then use 8000rpm Centrifuge for 10 minutes to remove the supernatant to obtain the primary precipitate; add 95v / v% ethanol to the primary precipitate according to the ratio of material to liquid 1:30 (g:ml), and ultrasonicate for 3 hours at room temperature (25°C±1°C) to remove the three Terpenoids, and then centrifuged under the same conditions to obtain the secondary precipitate; add deionized water to the secondary precipitate according to the ratio of solid to liquid 1:50 (g:ml), soak at 45 °C for 1 hour to remove water-soluble protein, and use the same After centrifugation, the precipitate obtained three times was dried at 60°C to obtain crude chitin;

[0051] (2) Get 1g of crude chitin, add 30ml concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com