No-yellowing easily-reworked UV mercury lamp curing EVA optical adhesive film and preparation method thereof

An optical glue, no yellowing technology, applied in the direction of adhesives, etc., can solve the problems of rising yellowness value, difficult rework, affecting the stability of electronic products, etc., to achieve good long-term yellowing resistance, easy to rework, to solve problems and parts. Effects of damage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

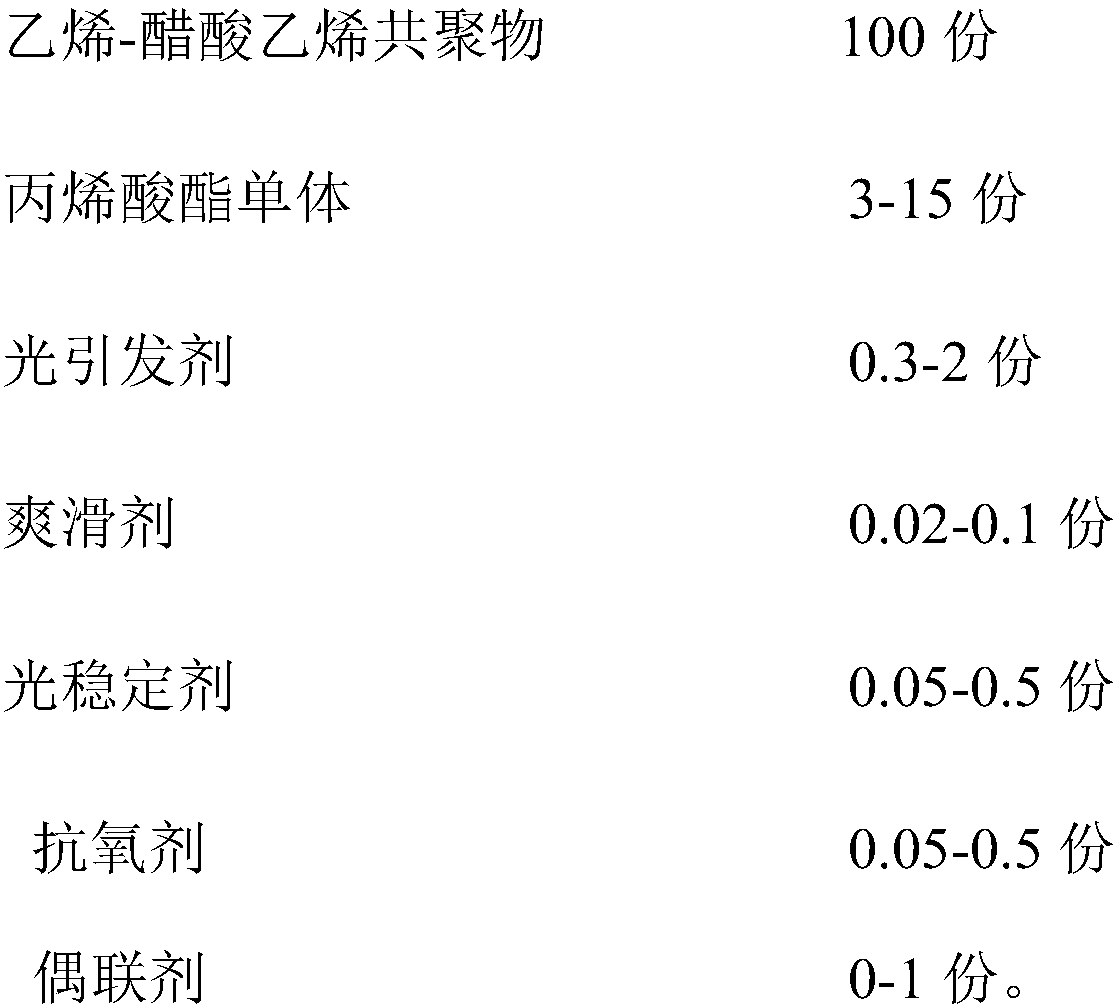

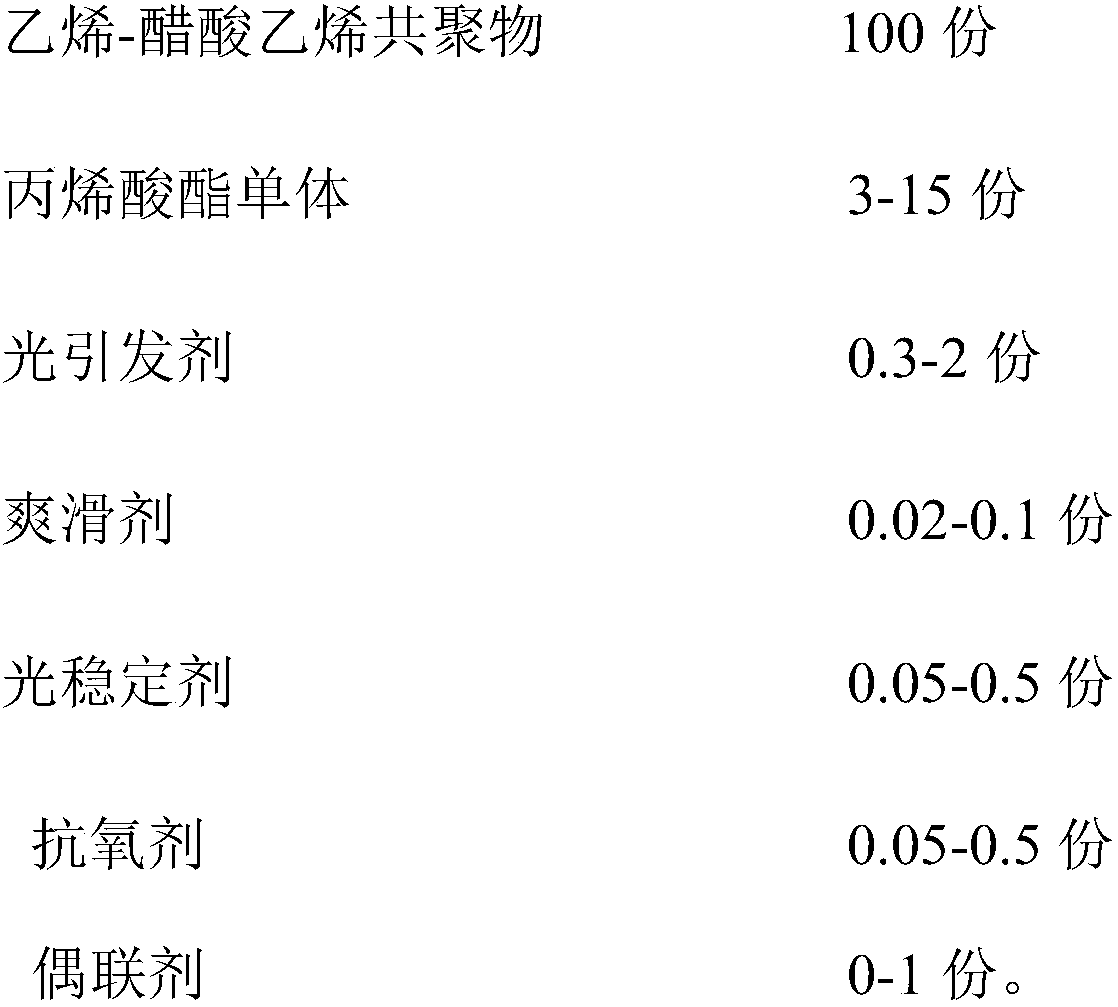

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of the UV curable EVA optical adhesive film, which comprises the following steps:

[0036] Pre-mixing step: put ethylene-vinyl acetate copolymer, acrylate monomer, photoinitiator, light stabilizer, antioxidant, coupling agent, and slippery agent into a cone with a wall temperature of 40°C according to the above formula Premixing in a mixer until all the additives are absorbed to obtain a premix;

[0037] Forming steps: Then put the premixed material into the hopper of the tape casting machine, melt it at 80-110°C, and go through the processes of plasticizing, extruding, stretching, pulling, and winding to obtain an EVA optical film.

[0038] The step of curing and cross-linking: after the EVA optical film is laminated and pre-pressed by a vacuum press at 60-80° C., it is irradiated with 2500 mj under a high-pressure mercury lamp with a light intensity of 3 kw to complete the curing and cross-linking.

[0039] The...

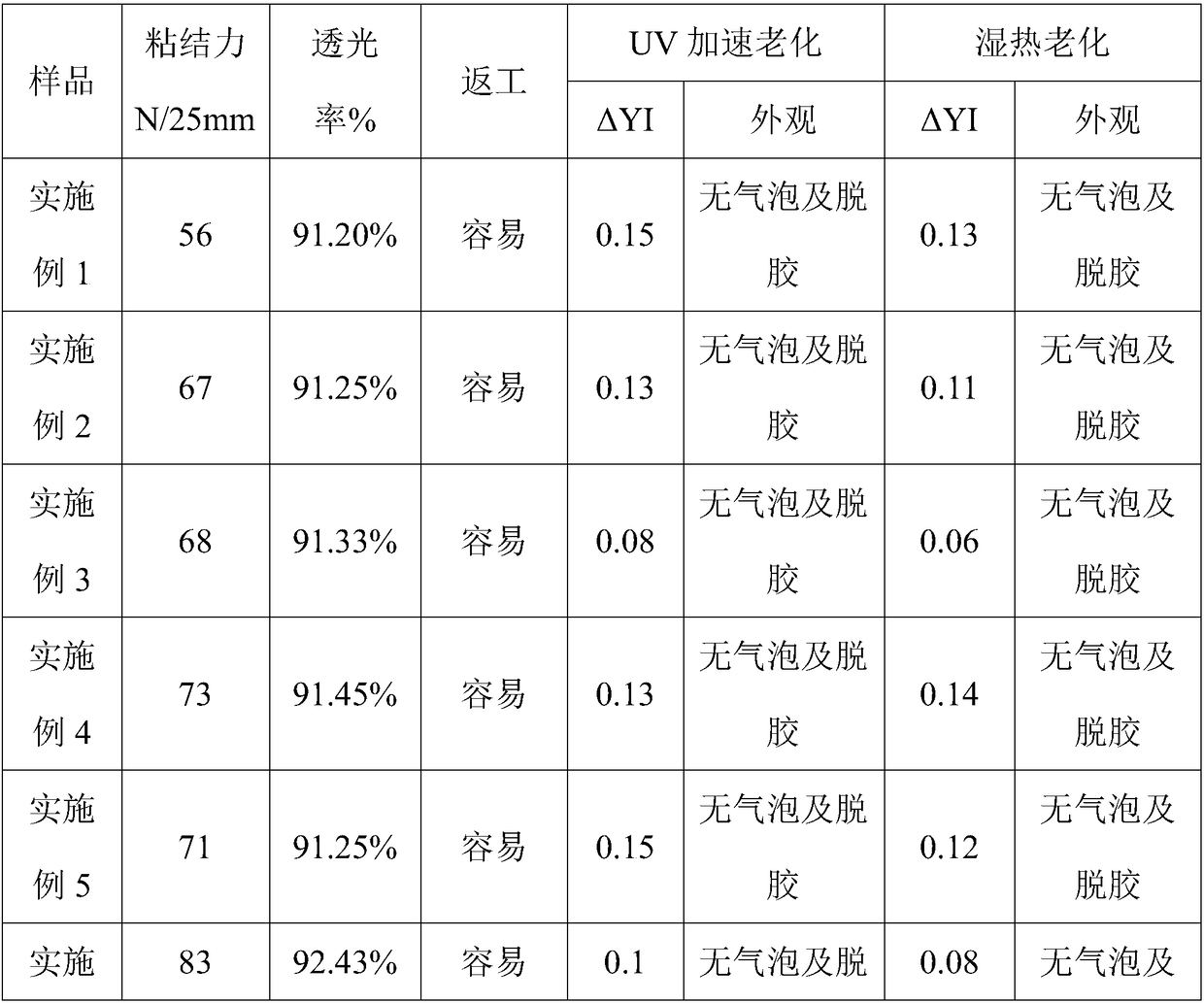

Embodiment 1

[0042] UV mercury light curing EVA optical adhesive film, thickness 0.15mm, its raw materials are: 100 parts of EVA, 6 parts of acrylate monomer, 0.6 parts of photoinitiator, 0.05 part of light stabilizer, 0.1 part of antioxidant, 0.5 part of even Joint agent, 0.1 parts of slip agent; wherein EVA is composed of vinyl acetate content 26%, melting point 72 ℃, acrylate monomer is composed of isobornyl acrylate and triallyl isocyanurate according to the quality of 2:1 Ratio composition, photoinitiator 1173 (2-hydroxy-2-methyl-1-phenylacetone), antioxidant 264, coupling agent by γ-(methacryloyloxy) propyltrimethoxysilane The composition is mixed evenly by a mixer, put into a casting machine, and plasticized, extruded, stretched, drawn, and wound at 110°C to make a film with a thickness of about 0.15mm.

Embodiment 2

[0044] UV mercury light curing EVA optical adhesive film, thickness 0.2mm, its raw materials are: 100 parts of EVA, 8 parts of acrylate monomer, 1 part of photoinitiator, 0.05 part of light stabilizer, 0.1 part of antioxidant, 0.3 part of dual Joint agent, 0.05 parts of slip agent; wherein EVA is composed of vinyl acetate content of 28% and melting point of 70°C, and acrylate monomer is composed of isobornyl acrylate and triallyl isocyanurate according to the quality of 3:1 Ratio composition, photoinitiator 1173 (2-hydroxy-2-methyl-1-phenylacetone), antioxidant 264, coupling agent by γ-(methacryloyloxy) propyltrimethoxysilane The composition is mixed evenly by a mixer, put into a casting machine, and plasticized, extruded, stretched, drawn, and wound at 100°C to make a film with a thickness of about 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com