Organic binder for solar battery aluminum paste and preparation method thereof

A technology for solar cells and organic adhesives, which is applied to conductive materials, circuits, electrical components and other directions dispersed in non-conductive inorganic materials, can solve the problems of insufficient viscosity of organic adhesives for aluminum pastes for solar cells, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

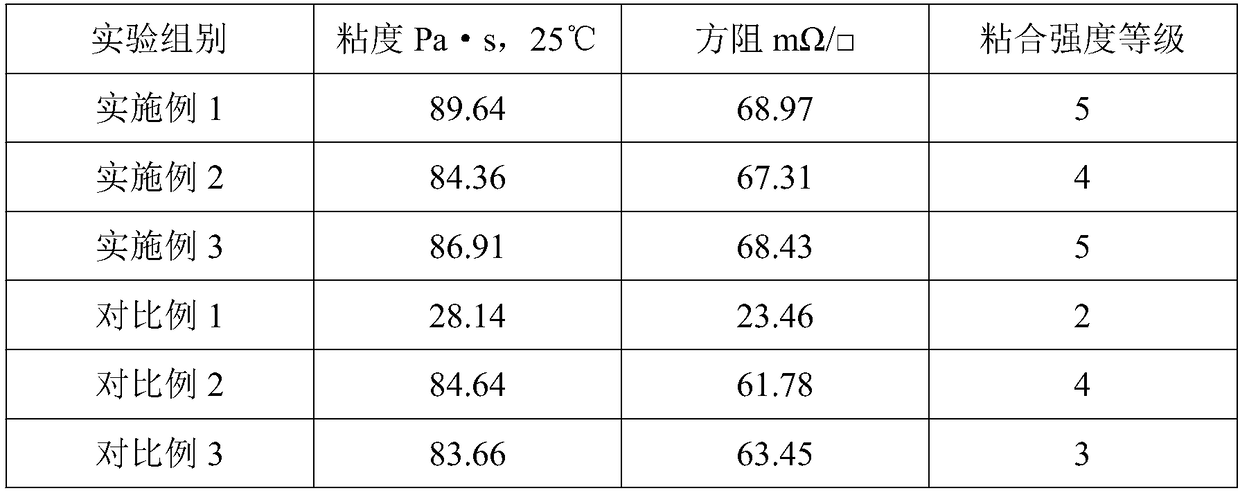

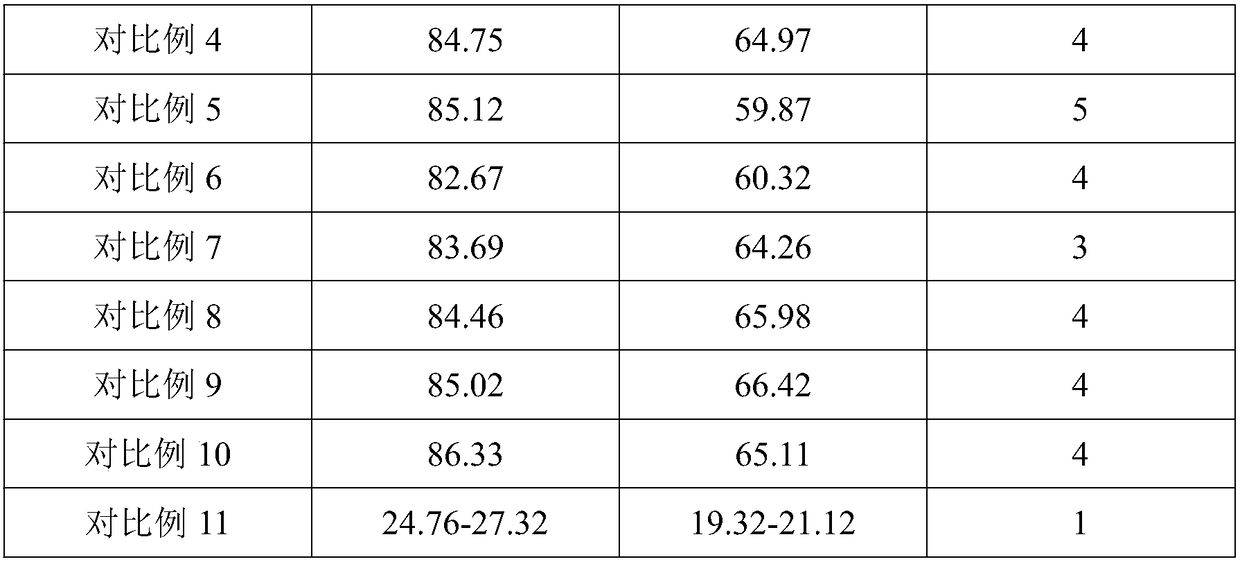

Examples

preparation example Construction

[0019] The preparation method of organic binder for described solar cell aluminum paste, comprises the following steps:

[0020] S1. Polyvinyl butyral resin, ethanol cellosolve acetate, butyl cellosolve acetate, ethyl cellosolve, BYK-163, BYK-P104S, BYK-110, BYK-141, BYK-052 and BYK -066N mix evenly, heat up to 60-90°C, keep warm for 20-30min, then stir at 650-850r / min for 1-2h, cool to room temperature to obtain the base material;

[0021] S2. Mix ethyl cellulose, polyvinyl acetal, acrylic modified alkyd resin, terpineol, butyl carbitol, hydrogen castor oil, tributyl citrate, furoic acid and bentonite evenly, and heat up To 85-95°C, keep warm for 30-50min, then stir at 1500-2500r / min for 10-30min, cool to room temperature to obtain modified material;

[0022] S3. Raise the temperature of the modified material to 90-110°C, then add the base material and mix evenly, continue to heat up to 120-130°C, keep warm for 1-3h, stir at 1500-2500r / min for 20-40min, cool to room temperat...

Embodiment 1

[0025] An organic adhesive for solar cell aluminum paste, in parts by weight, comprising the following raw materials: 22.9 parts of polyvinyl butyral resin, 6.7 parts of ethyl cellulose, 8.1 parts of polyvinyl acetal, acrylic acid modified alcohol 3.2 parts of acid resin, 4.5 parts of terpineol, 8.4 parts of butyl carbitol, 4.1 parts of hydrogen castor oil, 8.3 parts of ethanol cellosolve acetate, 3.2 parts of butyl cellosolve acetate, 4.6 parts of ethyl cellosolve, 7.4 parts of BYK-163, 3.2 parts of BYK-P104S, 5.6 parts of BYK-110, 3.2 parts of BYK-141, 6.5 parts of BYK-052, 4.6 parts of BYK-066N, 5.3 parts of tributyl citrate, 3.4 parts of furoic acid, 8.9 parts of bentonite.

[0026] The preparation method of organic binder for described solar cell aluminum paste, comprises the following steps:

[0027]S1. Polyvinyl butyral resin, ethanol cellosolve acetate, butyl cellosolve acetate, ethyl cellosolve, BYK-163, BYK-P104S, BYK-110, BYK-141, BYK-052 and BYK -066N mix evenly,...

Embodiment 2

[0031] An organic adhesive for solar cell aluminum paste, in parts by weight, comprising the following raw materials: 15 parts of polyvinyl butyral resin, 9 parts of ethyl cellulose, 6 parts of polyvinyl acetal, acrylic acid modified alcohol 5 parts of acid resin, 2 parts of terpineol, 9 parts of butyl carbitol, 4 parts of hydrogen castor oil, 9 parts of ethanol cellosolve acetate, 2 parts of butyl cellosolve acetate, 6 parts of ethyl cellosolve, 4 parts of BYK-163, 5 parts of BYK-P104S, 3 parts of BYK-110, 5 parts of BYK-141, 3 parts of BYK-052, 5 parts of BYK-066N, 3 parts of tributyl citrate, 4 parts of furoic acid, soap 6 parts of soil.

[0032] The preparation method of organic binder for described solar cell aluminum paste, comprises the following steps:

[0033] S1. Polyvinyl butyral resin, ethanol cellosolve acetate, butyl cellosolve acetate, ethyl cellosolve, BYK-163, BYK-P104S, BYK-110, BYK-141, BYK-052 and BYK -066N mix evenly, heat up to 60-90°C, keep warm for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com