Colored quantum dot photoluminescence material based on microcapsule electrophoresis as well as luminescence method and application thereof

A technology of microcapsules and quantum dots, applied in luminescent materials, chemical instruments and methods, optics, etc., can solve the problems of energy utilization, brightness, insufficient color gamut, many added layers, too thick materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a photoluminescent material based on microcapsule electrophoresis colored quantum dots, which includes a red microcapsule, a green microcapsule and a blue microcapsule, all of which have a diameter of 100 μm.

[0068] The red microcapsules include: a microcapsule wall cavity, a filtered electrophoretic display liquid that only passes through the blue band, positively charged CdSe / CdS quantum dots that emit red light, and the capsules are excited with a blue backlight; the green microcapsules The capsule includes: a microcapsule wall cavity, a filtered electrophoretic display liquid that only passes through the blue band, positively charged CdSe / CdS quantum dots that emit green light, and the capsule is excited with a blue backlight; the blue microcapsule includes: Microcapsule wall cavity, blue-only filtered electrophoretic display fluid, black polymer spheres of positively charged Sudan Black B dye combined with particle medium, the capsules are...

Embodiment 2

[0077] The photoluminescent material based on microcapsule electrophoresis colored quantum dots provided in this embodiment is exactly the same as that in Embodiment 1.

[0078] The color of the material is controlled as follows:

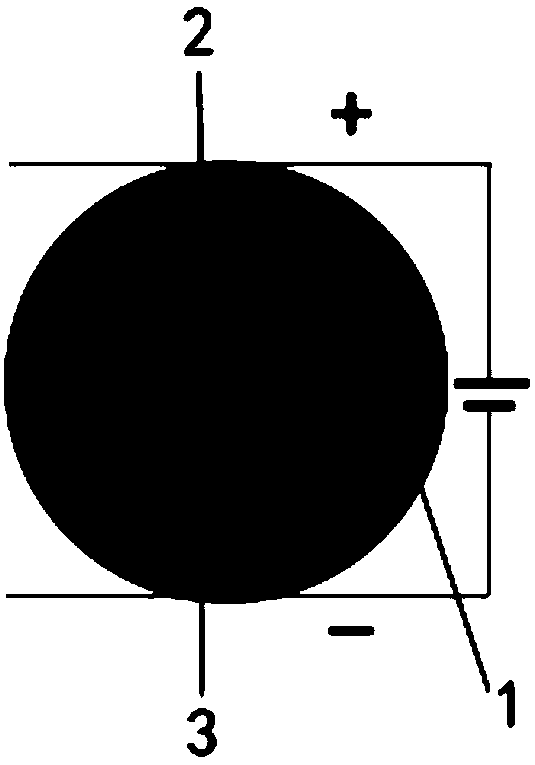

[0079] As shown in Figure 1(a), in this embodiment, the upper surface (top) of the red microcapsule is positively charged and the lower surface (bottom) is negatively charged, and the positively charged red quantum dots will be electrophoresed to the bottom and excited by the blue backlight The resulting red light will be absorbed by the filter material (filter electrophoretic display liquid), and the red microcapsules will not emit light at this time.

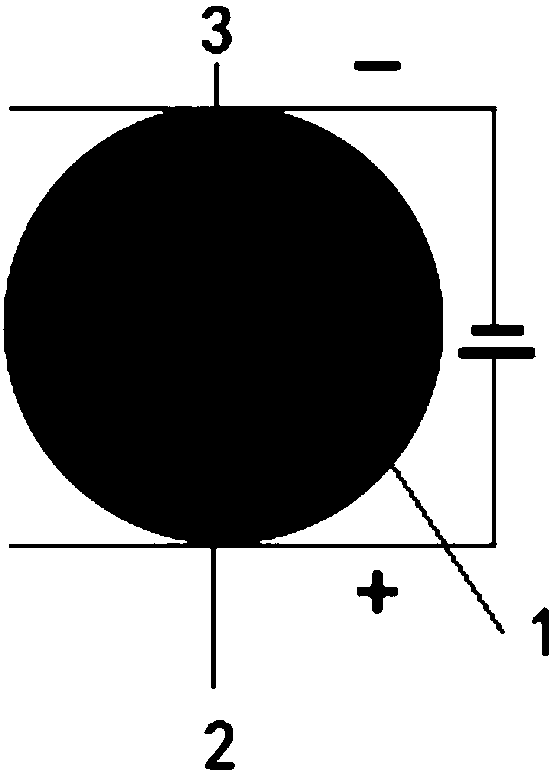

[0080] As shown in Figure 2(a), in this embodiment, the upper surface (top) of the green microcapsule is positively charged and the lower surface (bottom) is negatively charged. The green light generated after excitation will be absorbed by the filter material (filter electrophoretic display liquid...

Embodiment 3

[0084] The photoluminescent material based on microcapsule electrophoresis colored quantum dots provided in this example is exactly the same as that in Example 1 except that the quantum dots emitting red light, the quantum dots emitting green light, and the light-shielding particles are all negatively charged.

[0085] The color of the material is controlled as follows:

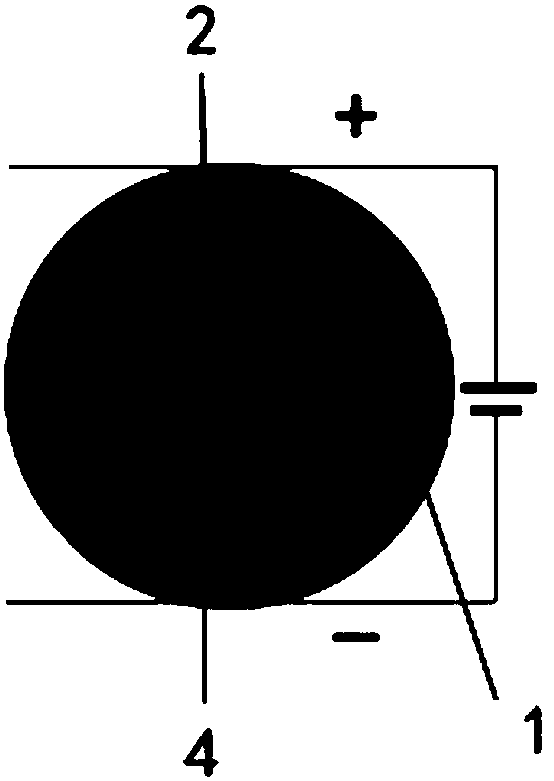

[0086] In this embodiment, the upper surface (top) of the red microcapsule is positively charged and the lower surface (bottom) is negatively charged, and the negatively charged red quantum dots will be electrophoresed to the top, and will be excited by the blue backlight to emit red light. Control the number of quantum dots in the upper layer to control the luminous flux.

[0087] In this embodiment, the upper surface (top) of the green microcapsule is negatively charged and the lower surface (bottom) is positively charged, and the negatively charged green quantum dots will be electrophoresed to the bottom, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com