Manganese dioxide-carbon nano tube composite catalyst based on palladium single-atom and preparation thereof

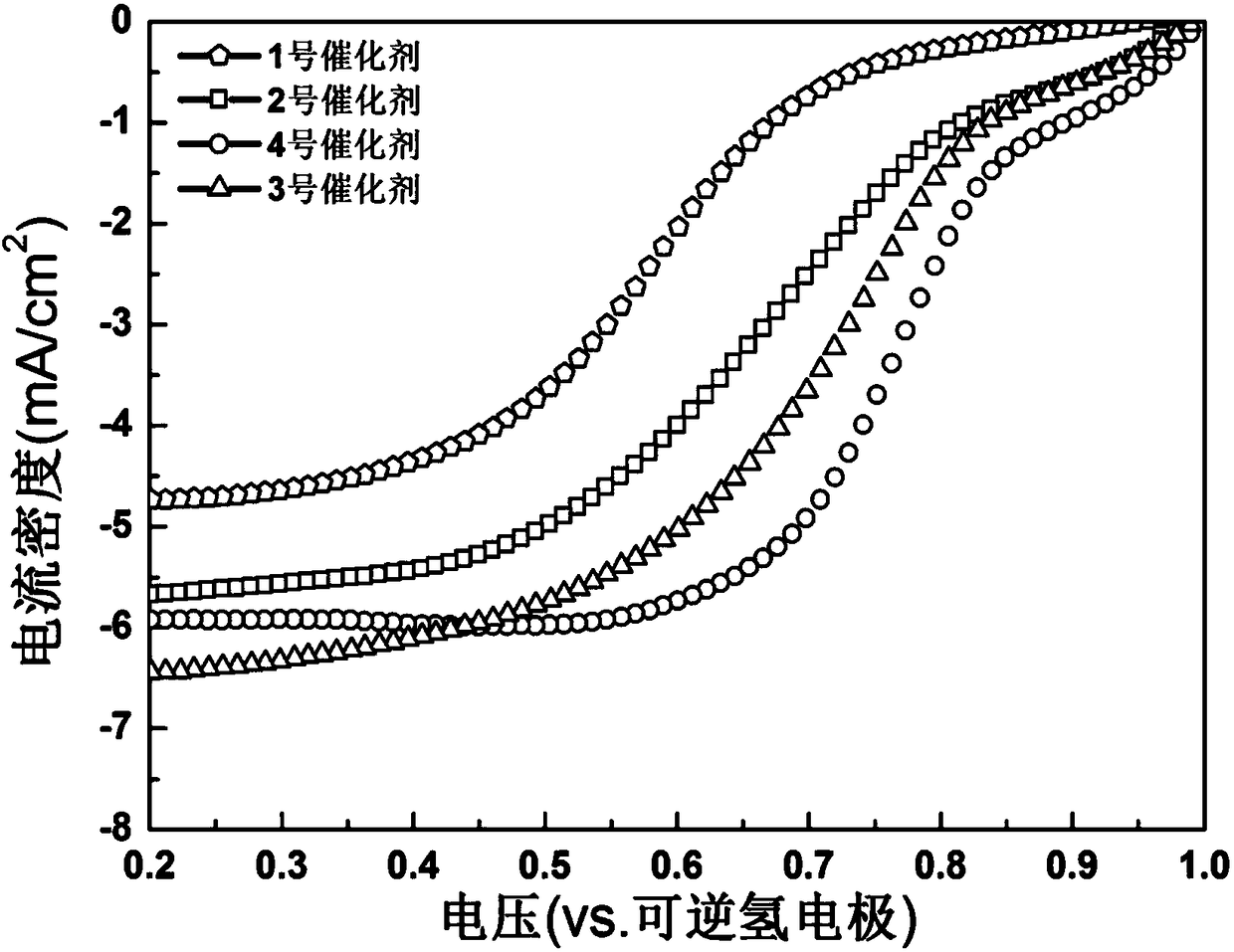

A technology of carbon nanotube composite and manganese dioxide, which is applied in the direction of fuel cell half-cells and primary battery half-cells, electrical components, battery electrodes, etc., can solve the problem of low catalyst mass activity and low utilization efficiency of silver atoms, etc. problems, achieve excellent electrocatalytic activity and stability, improve catalytic activity and stability, and increase the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0028] Example 1 Preparation of catalyst No. 1

[0029] 1) Add 0.9g of manganese sulfate, 2.6g of ammonium sulfate, and 1.2g of ammonium persulfate to 20mL of ultrapure water, stir electromagnetically to obtain a mixed solution;

[0030] 2) Transfer the mixed solution to a 25mL hydrothermal kettle, put it in an oven at 180℃, and react for 18h. The product is washed and dried to obtain MnO 2 Catalyst (Catalyst No. 1).

Embodiment 2

[0031] Example 2 Preparation of No. 2 Catalyst

[0032] In this embodiment, carbon nanotubes are added on the basis of embodiment 1. The specific preparation steps are as follows:

[0033] 1) Disperse 0.2g carbon nanotubes uniformly in 10mL ultrapure water by ultrasonic to obtain a carbon nanotube suspension;

[0034] 2) Add 0.9g of manganese sulfate, 2.6g of ammonium sulfate, and 1.2g of ammonium persulfate into 10mL of ultrapure water, stir electromagnetically to obtain a mixed solution;

[0035] 3) After the carbon nanotube suspension and the mixed solution are uniformly mixed, they are transferred to a 25mL hydrothermal kettle and placed in an oven at a temperature of 180°C for 18 hours. The product is washed and dried to obtain manganese dioxide-carbon nanotubes Composite catalyst (No. 2 catalyst).

Embodiment 3

[0036] Example 3 Preparation of No. 3 Catalyst

[0037] In this example, noble metal palladium is added on the basis of example 2. The specific preparation steps are as follows:

[0038] 1) Disperse 0.2g carbon nanotubes uniformly in 10mL ultrapure water by ultrasonic to obtain a carbon nanotube suspension;

[0039] 2) Add 0.9g of manganese sulfate, 2.6g of ammonium sulfate, 1.2g of ammonium persulfate and 100mg of palladium nitrate to 10mL of ultrapure water, stir electromagnetically to obtain a mixed solution;

[0040] 3) After the carbon nanotube suspension and the mixed solution are uniformly mixed, they are transferred to a 25mL hydrothermal kettle and placed in an oven at a temperature of 180°C for 18 hours. The product is washed and dried to obtain a palladium monoatom-based dioxide Manganese-carbon nanotube composite catalyst (catalyst 3).

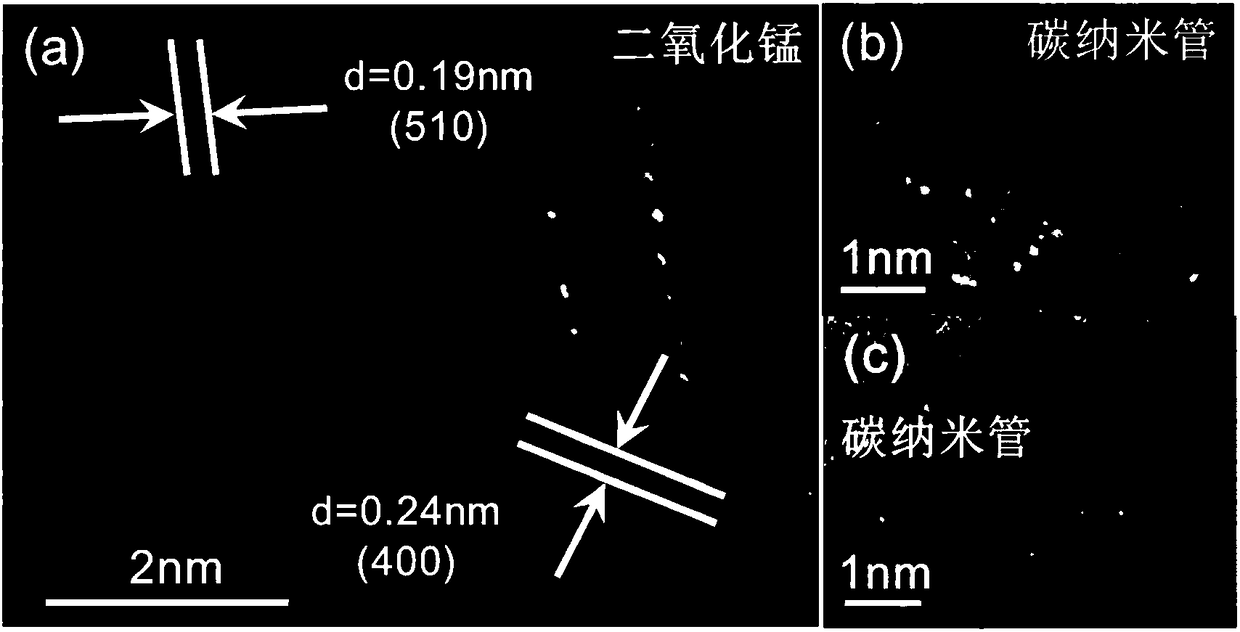

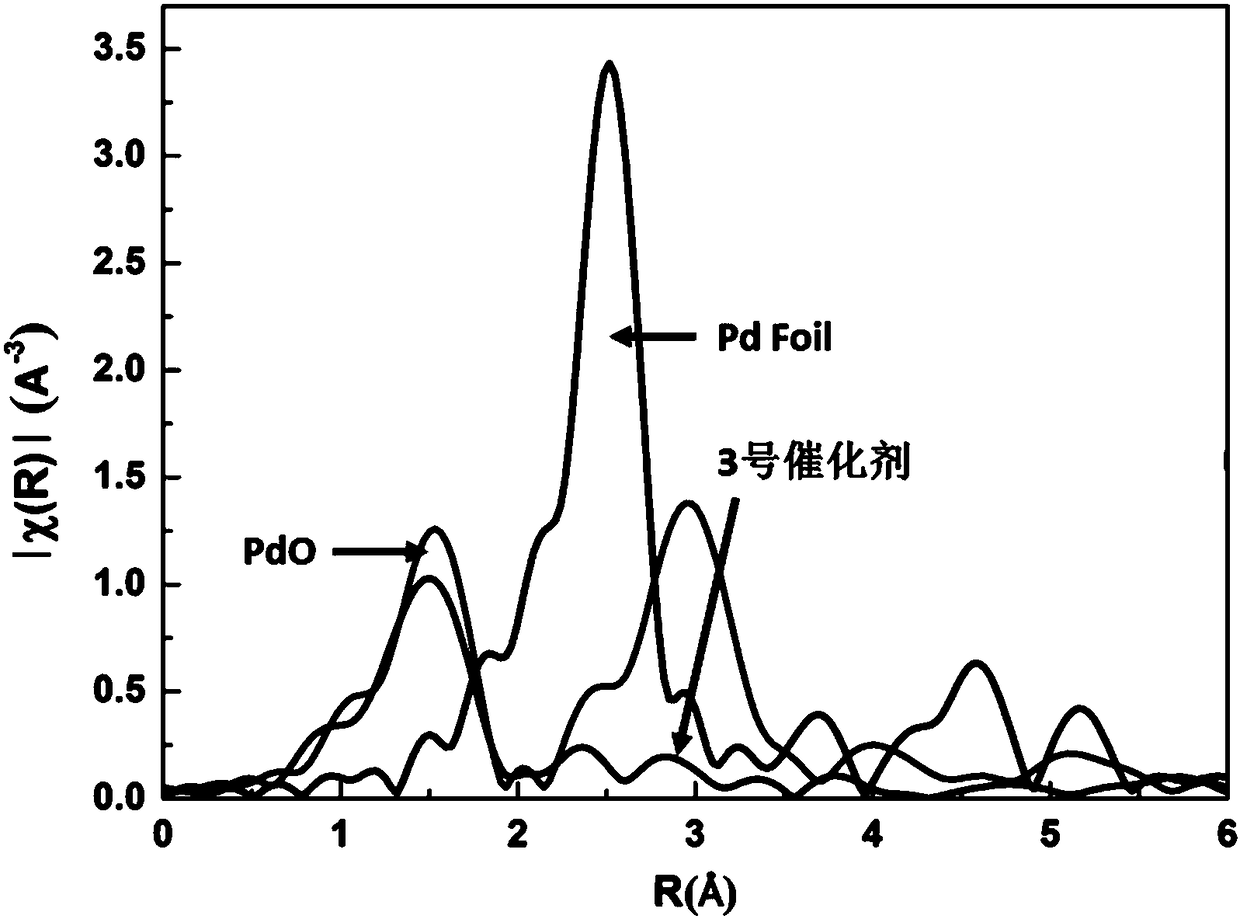

[0041] A spherical aberration electron microscope was used to characterize the atomic structure of the No. 3 catalyst prepared in this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com