Ceramic anilox roller and preparing process thereof

A preparation process and ceramic mesh technology, which is applied in the coating process of metal materials, the coating of printing machine rollers, coatings, etc., can solve the problems of high price, and achieve the effects of low production cost, excellent comprehensive performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

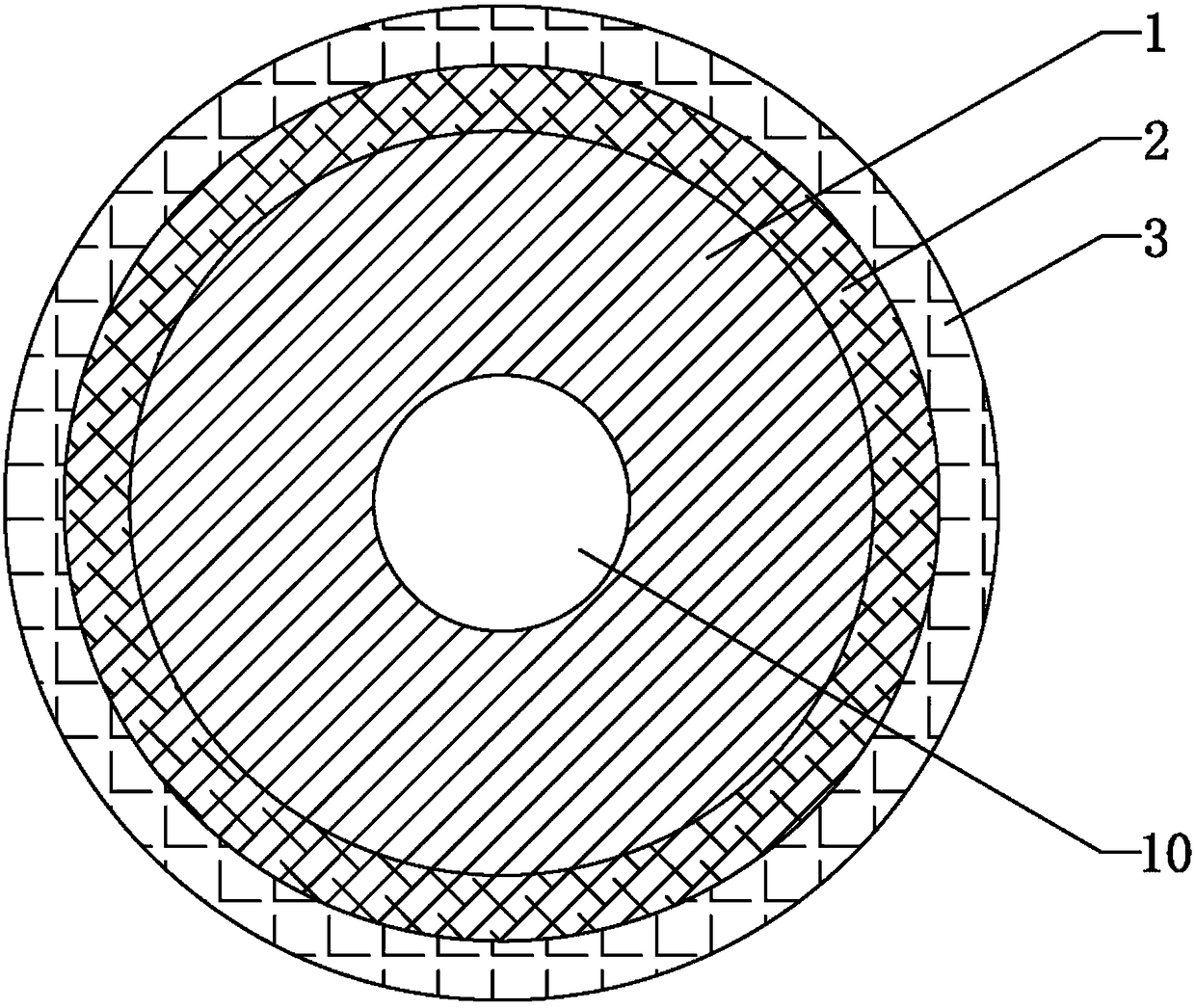

[0032] See figure 1 , a ceramic anilox roller, comprising a roller body 1, a nickel-chromium alloy layer 2 arranged on the outer surface of the roller body 1, and a chromium oxide ceramic layer 3 arranged on the outer surface of the nickel-chromium alloy layer 2, the outer side of the chromium oxide ceramic layer 3 The wall is provided with a texture for loading ink. Both ends of the roller body 1 are respectively welded with rotating shafts 10 .

[0033] The nickel-chromium alloy layer 2 includes the following elements by weight percentage: C: 0.08%, Si: 1%, Mn: 0.6%, Cr: 15%, Al: 0.1%, Fe: 1%, P: 0.02%, S : 0.015%, the balance being Ni.

[0034] The nickel-chromium alloy layer 2 also includes the following elements by weight percentage: W: 0.6%, B: 0.006% and Y: 0.06%.

[0035] The nickel-chromium alloy layer 2 also includes the following elements by weight percentage: Sc: 0.01%, Zr: 0.06%, As: 0.001% and Sr: 0.001%.

[0036] The nickel-chromium alloy layer 2 also includ...

Embodiment 2

[0051] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0052] The nickel-chromium alloy layer 2 includes the following elements by weight percentage: C: 0.085%, Si: 1.5%, Mn: 0.7%, Cr: 17%, Al: 0.2%, Fe: 3%, P: 0.025%, S : 0.018%, the balance being Ni.

[0053] The nickel-chromium alloy layer 2 also includes the following elements by weight percentage: W: 0.7%, B: 0.007% and Y: 0.07%.

[0054] The nickel-chromium alloy layer 2 also includes the following elements by weight percentage: Sc: 0.02%, Zr: 0.07%, As: 0.002% and Sr: 0.002%.

[0055] The nickel-chromium alloy layer 2 also includes the following elements in weight percentage: Yb: 0.02%, Sn: 0.1% and Hf: 0.007%.

[0056] In the step (2), the sandblasting material used for sandblasting is corundum sand.

[0057] In described step (3), spraying adopts plasma spraying device, and electric current is 400A, and the flow rate of argon gas and hydrogen is respectively 160L / min and 18L / min, a...

Embodiment 3

[0061] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0062] The nickel-chromium alloy layer 2 includes the following elements by weight percentage: C: 0.09%, Si: 2%, Mn: 0.8%, Cr: 19%, Al: 0.3%, Fe: 5%, P: 0.03%, S : 0.02%, the balance being Ni.

[0063] The nickel-chromium alloy layer 2 also includes the following elements by weight: W: 0.8%, B: 0.008% and Y: 0.08%.

[0064] The nickel-chromium alloy layer 2 also includes the following elements by weight percentage: Sc: 0.03%, Zr: 0.08%, As: 0.003% and Sr: 0.003%.

[0065] The nickel-chromium alloy layer 2 also includes the following elements by weight: Yb: 0.03%, Sn: 0.12% and Hf: 0.008%.

[0066] In the step (2), the sandblasting material used for sandblasting is quartz sand.

[0067] In described step (3), spraying adopts plasma spraying device, and electric current is 500A, and the flow rate of argon gas and hydrogen is respectively 180L / min and 22L / min, and powder delivery rate is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com