Sealing adhesive for mirror

An adhesive and mirror technology, applied in the directions of polymer adhesive additives, adhesive types, non-polymer adhesive additives, etc., can solve the problem of unsanitary, easy entry of insects and ants, and reduced service life of the mounting frame. problems, to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

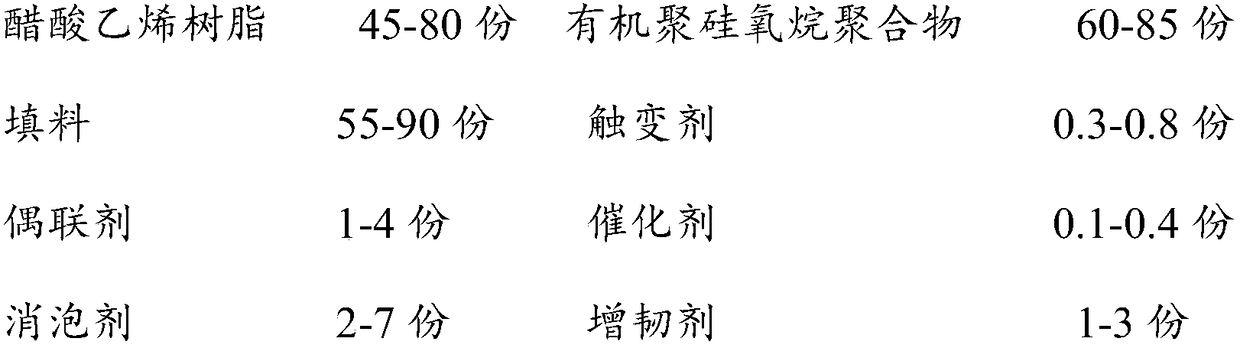

[0024] Mirror sealing adhesive, its raw material components by mass parts include:

[0025]

[0026] Its preparation method is:

[0027] Weigh the components of vinyl acetate resin, organopolysiloxane polymer, titanium dioxide, fumed silica, titanate coupling agent, organotin catalyst, emulsified silicone oil and polyamide resin.

[0028] Add component quantities of vinyl acetate resin, organopolysiloxane polymer, titanium dioxide, and fumed silica into the twin-screw extruder. The melt temperature of the screw is 140°C, the vacuum degree is 0.11MPa, and the rotation speed is 400r / min, the extruded mixture is cooled to obtain the mixture a;

[0029] Add the mixture a to the reaction kettle, add titanate coupling agent and organotin catalyst, heat up at a rate of 8°C / min, raise the temperature to 160°C, stir at a speed of 80r / min, and stir for 15min to obtain mixture b;

[0030] Put the mixture b in a high-speed dispersing mixer, add emulsified silicone oil and polyamide ...

Embodiment 2

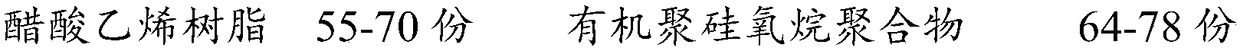

[0033] Mirror sealing adhesive, its raw material components by mass parts include:

[0034]

[0035] Its preparation method is:

[0036] Weigh the components of vinyl acetate resin, organopolysiloxane polymer, talcum powder, precipitated silica, titanate coupling agent, stannous octoate, higher alcohol fatty acid ester complex and nylon 66.

[0037] Add component amounts of vinyl acetate resin, organopolysiloxane polymer, talc powder, and precipitated silica into the twin-screw extruder. The melt temperature of the screw is 170°C, the vacuum degree is 0.1MPa, and the rotation speed is 430r / min, the extruded mixture is cooled to obtain the mixture a;

[0038] Add mixture a to the reaction kettle, add titanate coupling agent and stannous octoate, heat up at a rate of 7°C / min, raise the temperature to 145°C, stir at a speed of 50r / min, and stir for 19min to obtain mixture b;

[0039] Put the mixture b in a high-speed dispersing mixer, add the high-carbon alcohol fatty acid ...

Embodiment 3

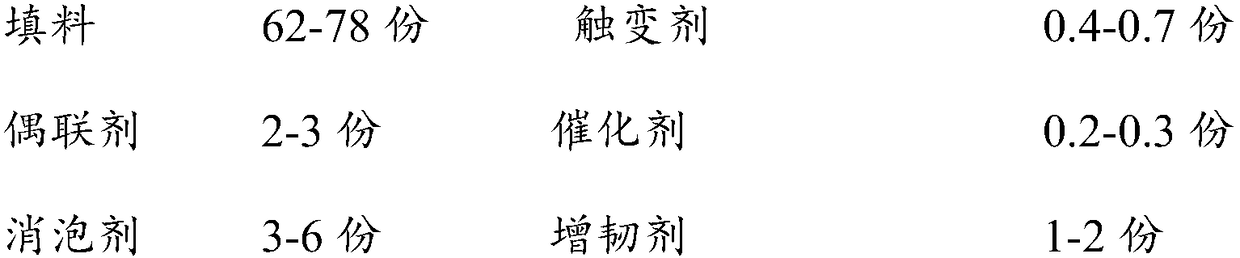

[0042] Mirror sealing adhesive, its raw material components by mass parts include:

[0043]

[0044] Its preparation method is:

[0045] Vinyl acetate resin, organopolysiloxane polymer, calcium carbonate, organobentonite, organobentonite, dibutyltin dilaurate, polyoxyethylene polyoxypropylene pentaerythritol ether and nylon 610 were weighed.

[0046] Add component quantities of vinyl acetate resin, organopolysiloxane polymer, calcium carbonate, and organobentonite into the twin-screw extruder. The melt temperature of the screw is 180°C, the vacuum degree is 0.07MPa, and the rotation speed is 550r / min , cooling the extruded mixture to obtain compound a;

[0047] Add mixture a to the reaction kettle, add organic bentonite and dibutyltin dilaurate, heat up at a rate of 5°C / min, raise the temperature to 120°C, stir at a speed of 40r / min, and stir for 20min to obtain mixture b;

[0048] Put the mixture b in a high-speed dispersion mixer, add polyoxyethylene polyoxypropylene pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com