A fermentation process using non-Saccharomyces cerevisiae to improve the aroma quality of ice wine

A technology of Saccharomyces cerevisiae and wine, which is applied in the field of fermentation technology, can solve problems that need to be developed urgently, and achieve the effect of improving aroma quality and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Example 1, the acquisition of Mei Mei Miqi Yeast CVE-MP20

[0038]First, screening and identification of strains CVE-MP20

[0039]A strain was screened during the natural fermentation of the ice grape, named strain CVE-MP20.

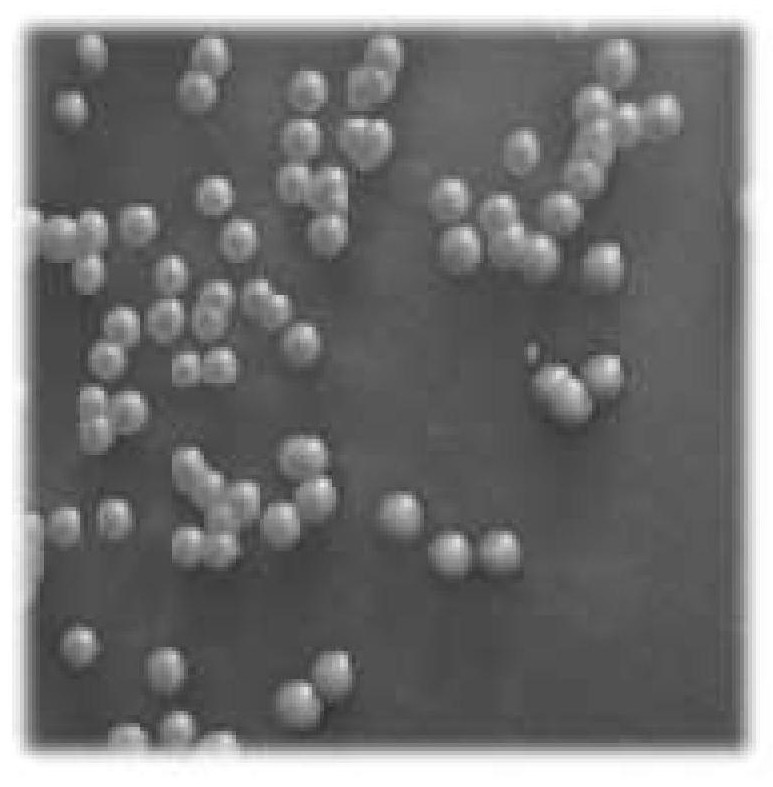

[0040]The morphological identification results of strain CVE-MP20figure 1 .

[0041]The 26s RDNA sequence of strain CVE-MP20 was amplified and sequenced, and the sequencing results were shown in Sequence 1 of the sequence table.

[0042]After the above identification, it was determined that the strain CVE-MP20 belongs to Meiqi yeast Mei Mei Mei Yeamei, so it is renamed it to Mei Miqi yeast CVE-MP20.

[0043]Second, MME Meiqi Yeast's preservation

[0044]Metschnikowia Puleherrima CVE-MP20 has been stored in the General Micro Biological Center of China's Microbial Square Safety Management Committee on February 28, 2017 (referred to as CGMCC; address: No.1, Beichen West Road, Chaoyang District, Beijing 3 No., China Academy of Sciences Microbiology Research Institute; Zip Code: ...

Embodiment 2

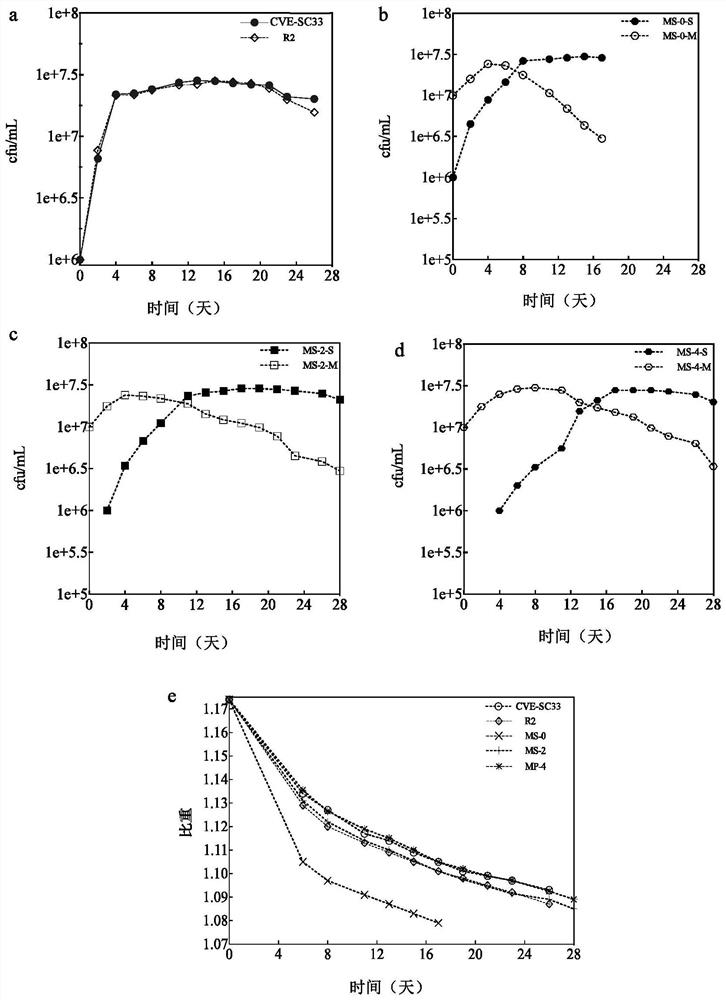

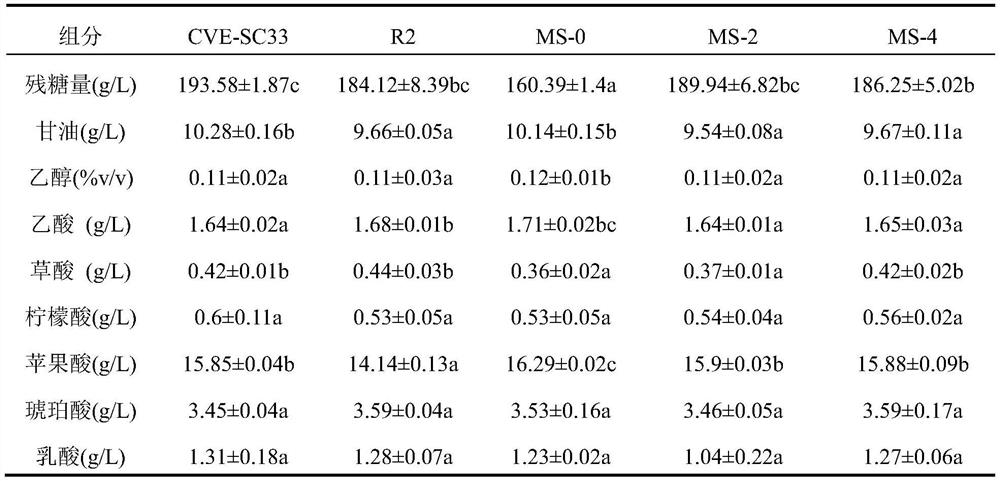

[0045]Example 2, the establishment of the process

[0046]First, the preparation of seed fluid

[0047]1. Western-ice grape juice is diluted with sterilized water to Bali sugar (brix) to be sterilized (90 ° C, 15 min), resulting in sterilization of grape juice.

[0048]2, inoculation of the brewing yeast CVE-SC33 in step 1 to the sterilization of grape juice (37 ° C, stand) to the bacteria to enter the pair of long-term.

[0049]3, transfer 1 body-to-step 2-cultured bacterial liquid to 100 parts by volume pre-treated Wydier ice grape juice culture (37 ° C, stand) to the bacteria to enter the diameters for a long time, to obtain a wine yeast CVE- SC33 seed fluid.

[0050]Prerequisites of Wyder ice grape juice: Detecting the sugar concentration in the ice grape juice in Westerner is 413g / L, to join the SO2The concentration of 20 mg / L in the pre-treated Wydal ice grape juice.

[0051]4, using Mei Mei Miqi yeast CVE-MP20 replacement of wine yeast CVE-SC33, followed by steps 2 and 3, to obtain Mei Mei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com