Method for preparing azelaic acid hydroxypropyl betacyclodextrin clathrate compound

A technology of hydroxypropyl azelaic acid and beta-cyclodextrin, which is applied in skin care preparations, medical preparations of non-active ingredients, drug combinations, etc., and can solve problems such as low solubility, limited application value, and irritation problem, to achieve simple production process, significant inclusion effect, and improve water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

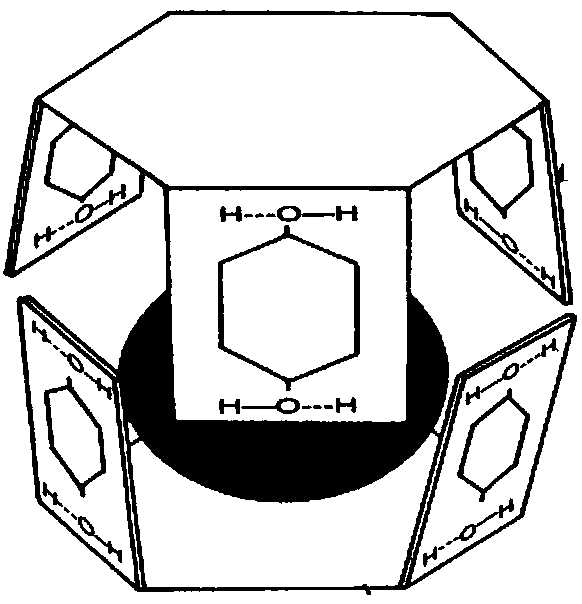

Image

Examples

Embodiment 1

[0026] Embodiment 1 A preparation method of azelaic acid hydroxypropyl beta cyclodextrin inclusion compound, the steps are as follows:

[0027] (1) In the reaction kettle, first add 25 kg of hydroxypropyl beta cyclodextrin, then add 50 kg of purified water, stir to dissolve it, and finally add 4.0 kg of azelaic acid, start heating, and heat up while stirring;

[0028] (2) Heating up to 80°C and keeping it for 0.5 hours, then cooling to 50°C for later use;

[0029] (3) Spray-dry the product obtained in step (2) with an LPG-20 spray dryer, control the inlet air temperature to 165°C, and the outlet air temperature to 60°C, and dry for 1 hour to obtain hydroxypropylbetazelate Cyclodextrin inclusion complex. Properties: This product is white or off-white amorphous or crystalline powder; strong hygroscopicity; easily soluble in water. The effective content of azelaic acid is 10%.

Embodiment 2

[0030] Embodiment 2 A preparation method of azelaic acid hydroxypropyl beta cyclodextrin inclusion compound, the steps are as follows:

[0031] (1) In the reaction kettle, first add 75 kg of hydroxypropyl beta cyclodextrin, then add 150 kg of purified water, stir to dissolve it, and finally add 12 kg of azelaic acid, start heating, and heat up while stirring;

[0032] (2) Heating up to 80°C and keeping it for 0.5 hours, then cooling to 50°C for later use;

[0033] (3) Spray-dry the product obtained in step (2) with an LPG-20 spray dryer, control the inlet air temperature to 205°C, and the outlet air temperature to 100°C, and dry for 2 hours to obtain hydroxypropylbetazelate Cyclodextrin inclusion complex. Properties: This product is white or off-white amorphous or crystalline powder; strong hygroscopicity; easily soluble in water; effective content of azelaic acid is 12%.

Embodiment 3

[0034] Embodiment 3 A preparation method of azelaic acid hydroxypropyl beta cyclodextrin inclusion compound, the steps are as follows:

[0035] (1) In the reaction kettle, first add 50 kg of hydroxypropyl beta cyclodextrin, then add 100 kg of purified water, stir to dissolve it, and finally add 8.0 kg of azelaic acid, turn on the heating, and heat up while stirring;

[0036] (2) Heating up to 80°C and keeping it for 0.5 hours, then cooling to 50°C for later use;

[0037] (3) The product obtained in step (2) is spray-dried using an LPG-20 spray dryer, the air inlet temperature is controlled at 185°C, the air outlet temperature is 80°C, and the product is dried for 1.5 hours to obtain hydroxypropylbetazelate Cyclodextrin inclusion complex. Properties: This product is white or off-white amorphous or crystalline powder; strong hygroscopicity; easily soluble in water; effective content of azelaic acid is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com