Discoloration process for dyeing and weaving wastewater treatment

A wastewater treatment and process technology, which is applied in textile industry wastewater treatment, multi-stage water treatment, biological water/sewage treatment, etc., can solve the problems that the color of wastewater cannot be completely removed, it is difficult to adapt to water quality, and the chroma of sewage can be reduced. The number of personnel used, the effect of fewer operators and low labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

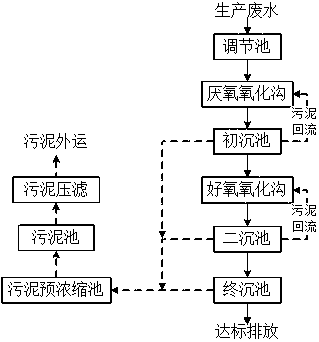

[0033] This embodiment provides a dyeing and weaving wastewater treatment and decolorization process, and the steps of the treatment and decolorization process are as follows:

[0034] Step 1: Pass the production wastewater into the regulating tank, and make the sewage homogeneous and even in volume through the regulating tank;

[0035] Step 2: passing the homogeneous and evenly measured waste liquid into an anaerobic oxidation ditch for hydrolysis and acidification;

[0036] Step 3: Pass the hydrolyzed waste liquid into the primary sedimentation tank for mud-water separation;

[0037] Step 4: send the supernatant in the primary sedimentation tank into the aerobic oxidation ditch fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com