Anti-static film

A technology of anti-static film and anti-static layer, which is applied in conductive coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as failure and high surface resistance of the film, and achieve good adhesion and excellent anti-static performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

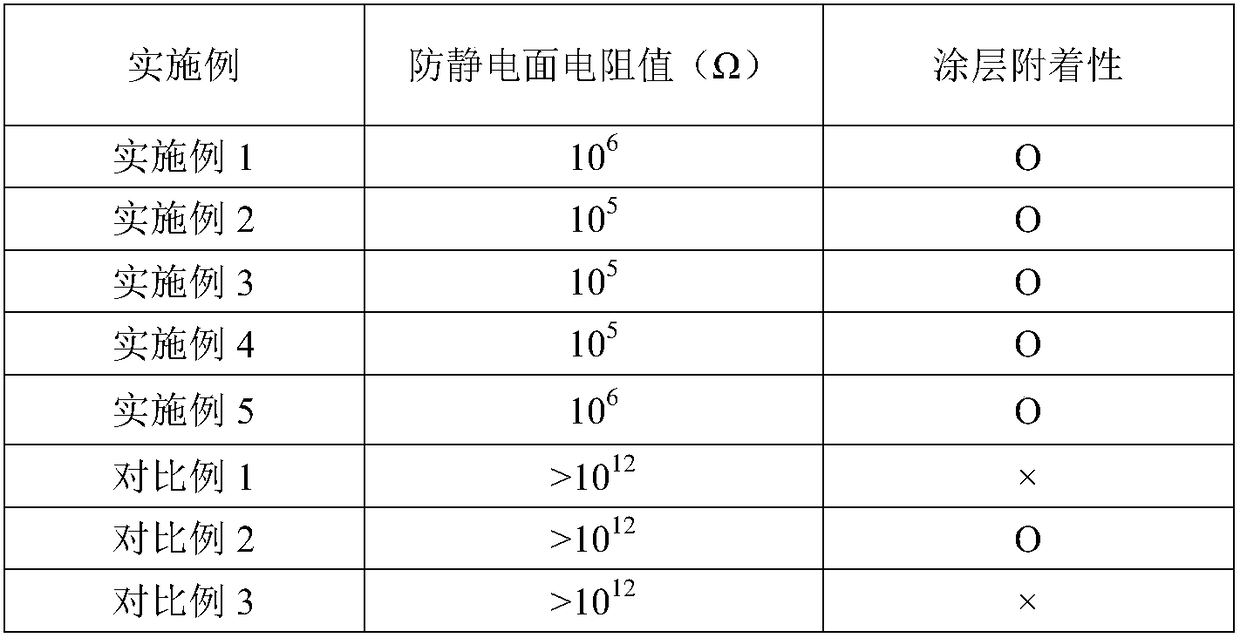

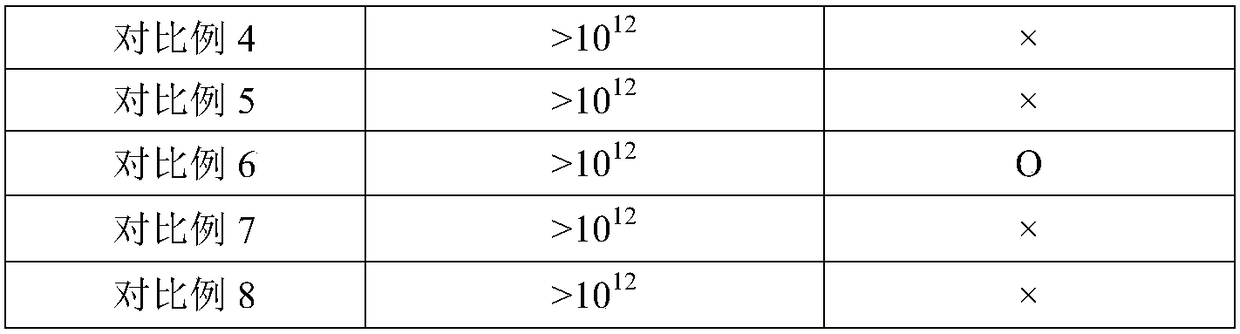

Examples

preparation example Construction

[0029] Antistatic film preparation method of the present invention, concrete steps are:

[0030] 1. First, the crystallized and dried polyester chips are sent to the corresponding extrusion system for melt extrusion, and cast on the rotating cooling roller.

[0031] 2. Preheat the cooled cast sheet to stretch longitudinally, and the longitudinal stretch ratio is 3 to 5 times.

[0032] 3. By means of gravure coating, wire rod coating, dip coating, etc., apply the prepared antistatic coating solution on one or both sides of the film after longitudinal stretching, wherein the wet coating amount 5g / m 2 ~7g / m 2 .

[0033] 4. After the film coated with antistatic coating solution is heated and dried at 60°C to 180°C, it is transversely stretched 3 to 5 times.

[0034] 5. After heat setting and winding at 180°C to 240°C, an antistatic film is obtained.

Embodiment 1

[0037] Preparation of antistatic coating solution:

[0038] Get 2g water-based carbon nanotube dispersion (the trade mark is CNTS-016, Suzhou Carbonfeng Graphene Technology Co., Ltd., the weight ratio of carbon nanotubes in the water-based carbon nanotube dispersion is 20%), 2g water-based polyurethane resin (the trade mark Huayue , Hefei Huayue New Material Technology Co., Ltd., the molar ratio of isocyanate and hydroxyl group contained in water-based polyurethane resin is 1:0.8, the hydroxyl value is 80mgKOH / g, and the elongation rate is 300%), 0.5g crosslinking agent (the brand is 710, Changzhou Lanya New Material Technology Co., Ltd.), 0.2g leveling agent (brand H6-1, Dongguan Bocheng Chemical Co., Ltd.), 0.1g defoamer (brand F12, Dongguan Defeng defoamer Co., Ltd.), 0.2g wetting agent (brand name is Silok-8008, Guangzhou Silok Chemical Co., Ltd.) was added to 95g water, and dispersed evenly with a high-shear emulsifier to make an antistatic coating solution.

[0039] Pre...

Embodiment 2

[0042] Preparation of antistatic coating solution:

[0043] Get 6g water-based carbon nanotube dispersion (the trade mark is CNTS-016, Suzhou Carbonfeng Graphene Technology Co., Ltd., the weight ratio of carbon nanotubes in the water-based carbon nanotube dispersion is 25%), 8g water-based polyurethane resin (the trade mark PU- 2840, Yuheng Environmental Protection Materials Co., Ltd., the molar ratio of isocyanate and hydroxyl group contained in water-based polyurethane resin is 2:1, the hydroxyl value is 120mgKOH / g, and the elongation is 500%), 1.0g crosslinking agent (grade 710 , Changzhou Lanya New Material Technology Co., Ltd.), 1g leveling agent (brand H6-1, Dongguan Bocheng Chemical Co., Ltd.), 1g defoamer (brand F12, Dongguan Defeng Defoamer Co., Ltd.) 1. 1g wetting agent (brand name is Silok-8008, Guangzhou Silok Chemical Co., Ltd.) was added to 82g water, and dispersed evenly with a high-shear emulsifier to make a kind of antistatic coating liquid.

[0044] Preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com