Non-metallic polymer carbon point with room temperature phosphorescent performance as well as preparation method and application thereof

A room temperature phosphorescence and polymer technology, applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve the problems of complex synthesis, high price and limited types of metal-free room temperature phosphorescence materials, and achieve excellent room temperature phosphorescence properties and cost. Low cost and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

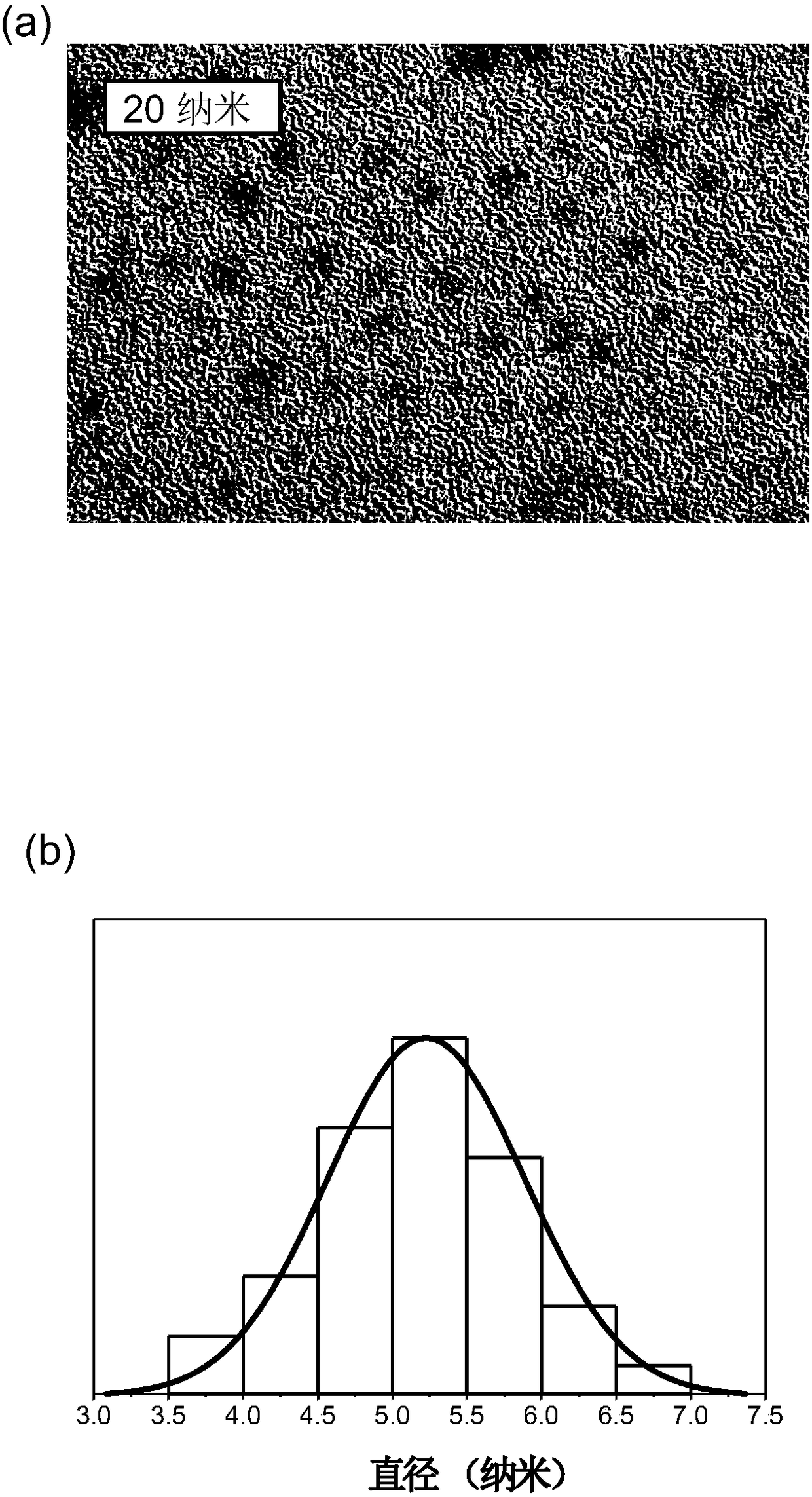

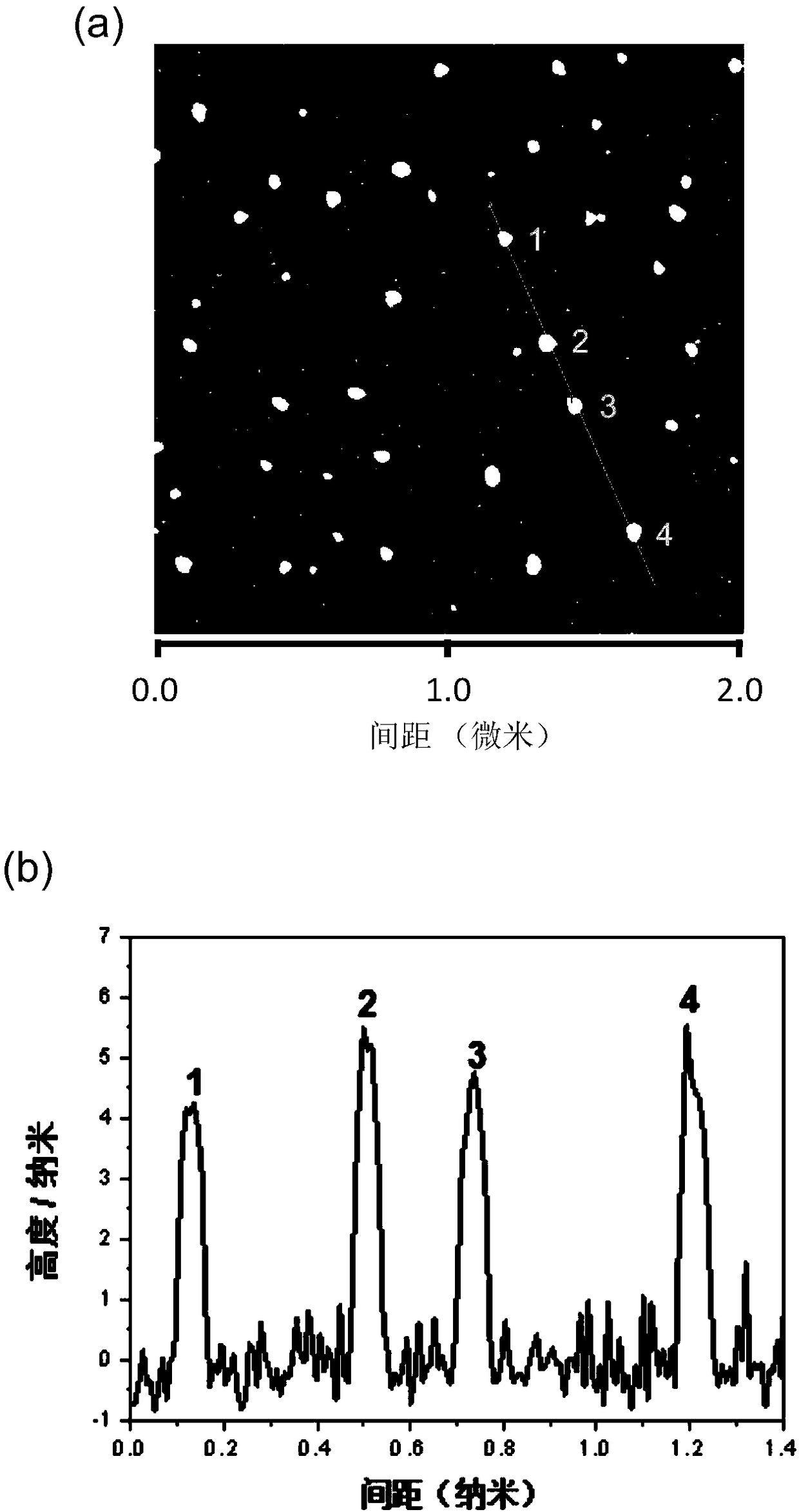

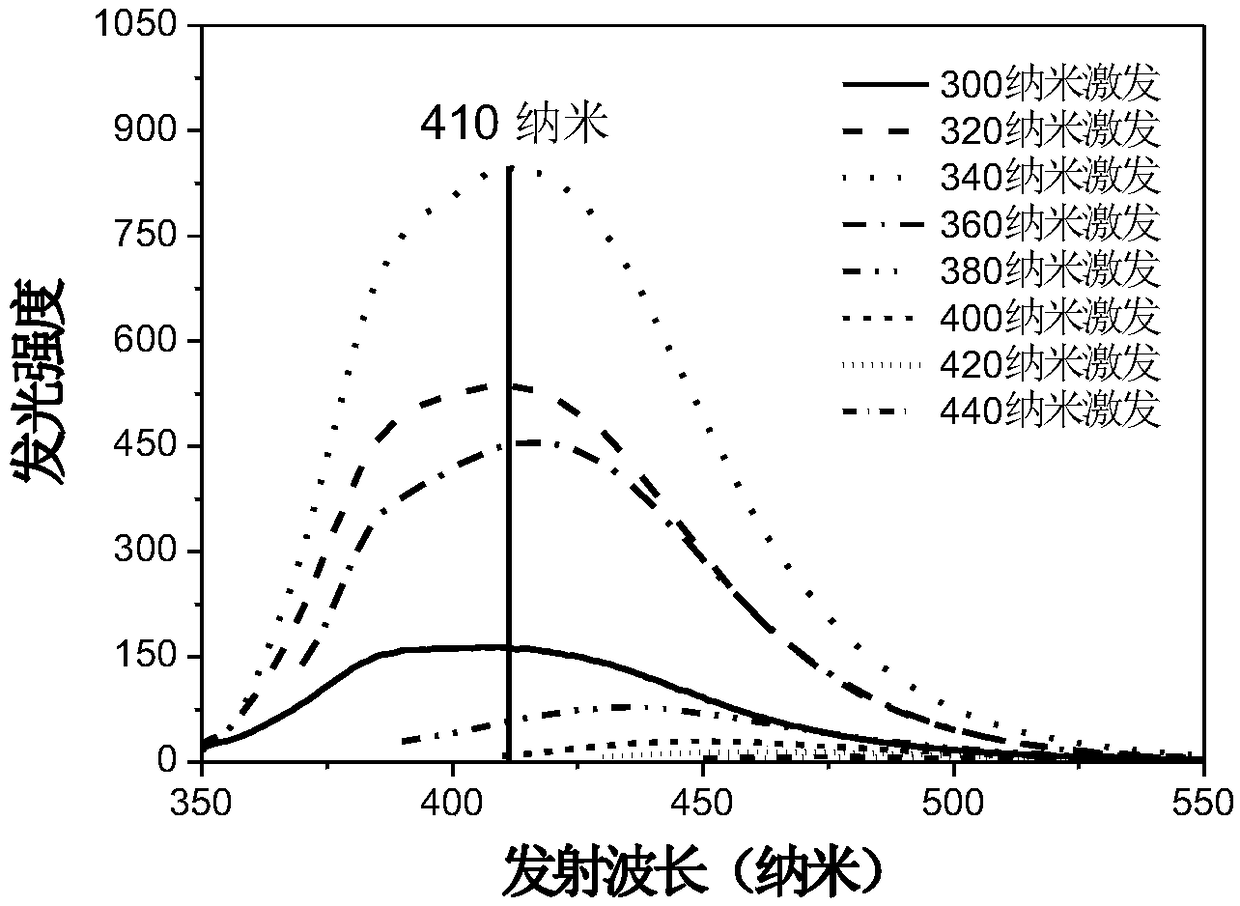

[0025] Preparation of polymer carbon dots 1

[0026] Weigh 72 mg of polyacrylic acid and dissolve it in 10 mL of deionized water; weigh 140 μL of ethylenediamine and add it to the above aqueous solution, and stir evenly with a glass rod. The above solution was transferred into a 20mL polytetrafluoroethylene-lined stainless steel reaction kettle, the lid of the kettle was tightened, and the reaction temperature was 200°C for 8 hours of hydrothermal reaction. Allow the reactor to cool down to room temperature naturally to obtain an aqueous solution of polymer carbon dots. Put the obtained polymer carbon dot aqueous solution into a dialysis bag with a molecular weight of 3500, and fully dialysis for 48 hours. Use a rotary evaporator to concentrate the collected dialyzed internal fluid and carry out vacuum freeze-drying (pressure 5Pa; temperature -25°C; drying time 24h) to obtain a solid powder of polymer carbon dots 1 with room temperature phosphorescence properties, and the pro...

Embodiment 2

[0029] Effect of Experimental Conditions on Properties of Polymer Carbon Dots 1

[0030] Raw material feeding ratio: Weigh 72 mg of polyacrylic acid and dissolve it in 10 mL of deionized water; measure different volumes of ethylenediamine (20, 40, 60, 80, 100, 120, 140, 160, 180, 200 μL) into the above aqueous solution, and use The glass rod was stirred evenly, and the subsequent preparation process was as in Example 1 to explore the influence of different feed ratios on the luminescent properties of polymer carbon dots under the same time and temperature conditions.

[0031] Reaction time: Weigh 72 mg of polyacrylic acid and dissolve it in 10 mL of deionized water; measure 140 μL of ethylenediamine and add it to the above aqueous solution, and stir evenly with a glass rod. The subsequent preparation process is as in Example 1. Under the condition of 200°C, hydrothermal treatment was performed for different times (2, 4, 6, 8, 10 h) to explore the effect of reaction time on the...

Embodiment 3

[0035] Study on the Stability of Polymer Carbon Dots 1

[0036] The preparation process was as in Example 1, and the obtained polymer carbon dot 1 was subjected to thermogravimetric analysis to determine its thermal stability. the result shows( Figure 10 ), the polymer carbon dots 1 hardly decomposes within 200 °C, indicating that it has good thermal stability.

[0037] The preparation process was as in Example 1. The obtained polymer carbon dots 1 were exposed to ultraviolet rays for 10 h, and the phosphorescence lifetime and luminous intensity within an hour were recorded, and the exposure time-lifetime / intensity curve was drawn. Such as Figure 11 As shown, after 10 h of UV exposure, the phosphorescence lifetime of polymer carbon dots 1 remained basically unchanged but the luminous intensity decreased slightly, indicating that polymer carbon dots had excellent anti-bleaching ability and stable luminescence performance.

[0038] The preparation process is as in Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com