Extraction and column chromatography group composition separation method of tobacco lipoid

A separation method and a technology of family composition, which are applied in the field of tobacco chemistry, can solve the problems of inability to fully and correctly reflect the quality of tobacco leaves, many interferences in spectrum analysis, and complex injection components, so as to reduce the sensitivity of equipment, reduce pollution, and simplify the detection of components. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

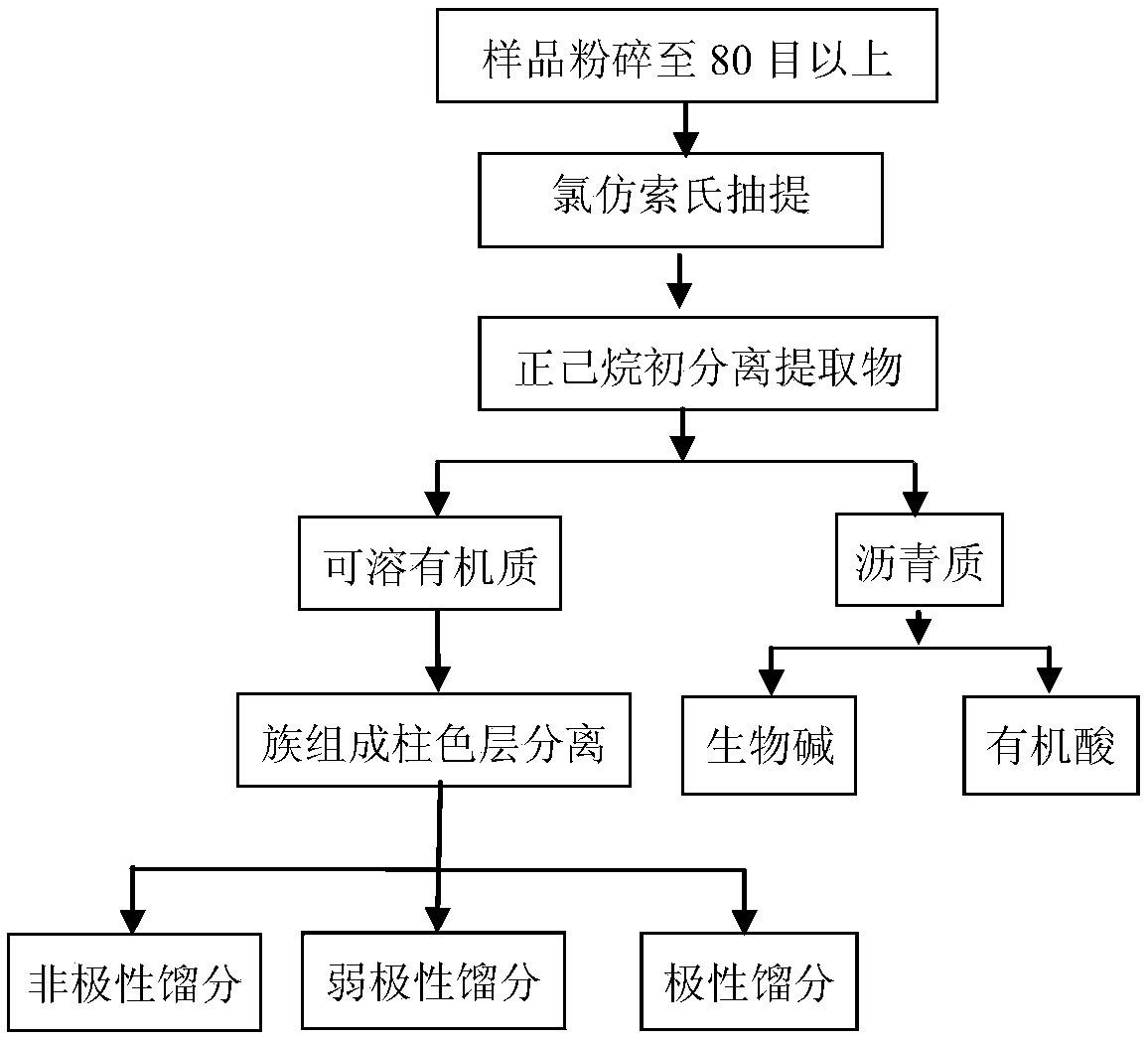

Method used

Image

Examples

Embodiment 1

[0045] Take the Shaanxi B3L tobacco sample as an example to describe in detail:

[0046] 1. Sample Extraction

[0047] Accurately weigh 6.0084g of crushed tobacco powder, pack it in 2 parts with dry filter paper extracted with chloroform (no smoke powder leaking out), add 300mL chromatographically pure chloroform into a 500mL flat-bottomed flask, and carry out Soxhlet extraction at 78°C for 24h (circulating cooling water at 8°C), concentrated to 10-15mL by a rotary evaporator, transferred to a 200mL beaker, dried in an oven at 40°C for 2 hours, and cooled to room temperature in a drying dish. Weigh to obtain 0.4791g extract, set aside.

[0048] 2. Asphaltene separation

[0049] Add 3 mL of dichloromethane to the extract in 1, heat and shake to dissolve completely. Then add 30mL of n-hexane, let it stand for 12h, transfer the supernatant to a 200mL beaker for use, then add 30mL of n-hexane to the extract and let it stand, take the supernatant and merge it into the first supern...

Embodiment 2

[0070] Take the Yunnan B3F tobacco leaf sample as an example to describe in detail:

[0071] 1. Sample Extraction

[0072] Accurately weigh the pulverized smoke powder 6.0073, pack it in 2 parts with dry filter paper extracted with chloroform (no smoke powder leaks out), add 300 mL of chromatographically pure chloroform into a 500 mL flat-bottomed flask, and carry out Soxhlet extraction at 75 °C for 24 hours ( circulating cooling water (8°C), concentrated to 10-15mL by a rotary evaporator, transferred to a 200mL beaker, dried in an oven at 40°C for 2 hours, and cooled to room temperature in a drying dish. Weigh to obtain 0.5121g extract, set aside.

[0073] 2. Asphaltene separation

[0074] Add 3 mL of dichloromethane to the extract in 1, heat and shake to dissolve completely. Then add 30mL of n-hexane, let it stand for 18h, transfer the supernatant to a 200mL beaker for use, then add 30mL of n-hexane to the extract and let it stand, take the supernatant and merge it into t...

Embodiment 3

[0082] Take the Hubei S6-H tobacco sample as an example to describe in detail:

[0083] 1. Sample Extraction

[0084] Accurately weigh 5.0002g of crushed tobacco powder, pack it in 2 parts with dry filter paper extracted with chloroform (no smoke powder leaking out), add 320mL chromatographically pure chloroform into a 500mL flat-bottomed flask, and carry out Soxhlet extraction at 70°C for 22 hours (circulating cooling water at 5°C), concentrated to 10-15mL by a rotary evaporator, transferred to a 200mL beaker, dried in an oven at 30°C for 4 hours, and cooled to room temperature in a drying dish. Weigh to obtain 0.4918g extract, set aside.

[0085] 2. Asphaltene separation

[0086] Add 2 mL of dichloromethane to the extract in 1, heat and shake to dissolve completely. Then add 25mL of n-hexane, let it stand for 4h, transfer the supernatant to a 200mL beaker, stand by, then add 25mL of n-hexane to the extract and let it stand, take the supernatant and merge it into the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com