Ceramic product forming device and forming method

A molding device and product technology, applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of different molding quality of multi-cavity molds, deformation of thin-walled ceramic products, and scrapping of ceramic products in one piece, so as to shorten the molding cycle , prevent heat loss, and realize the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

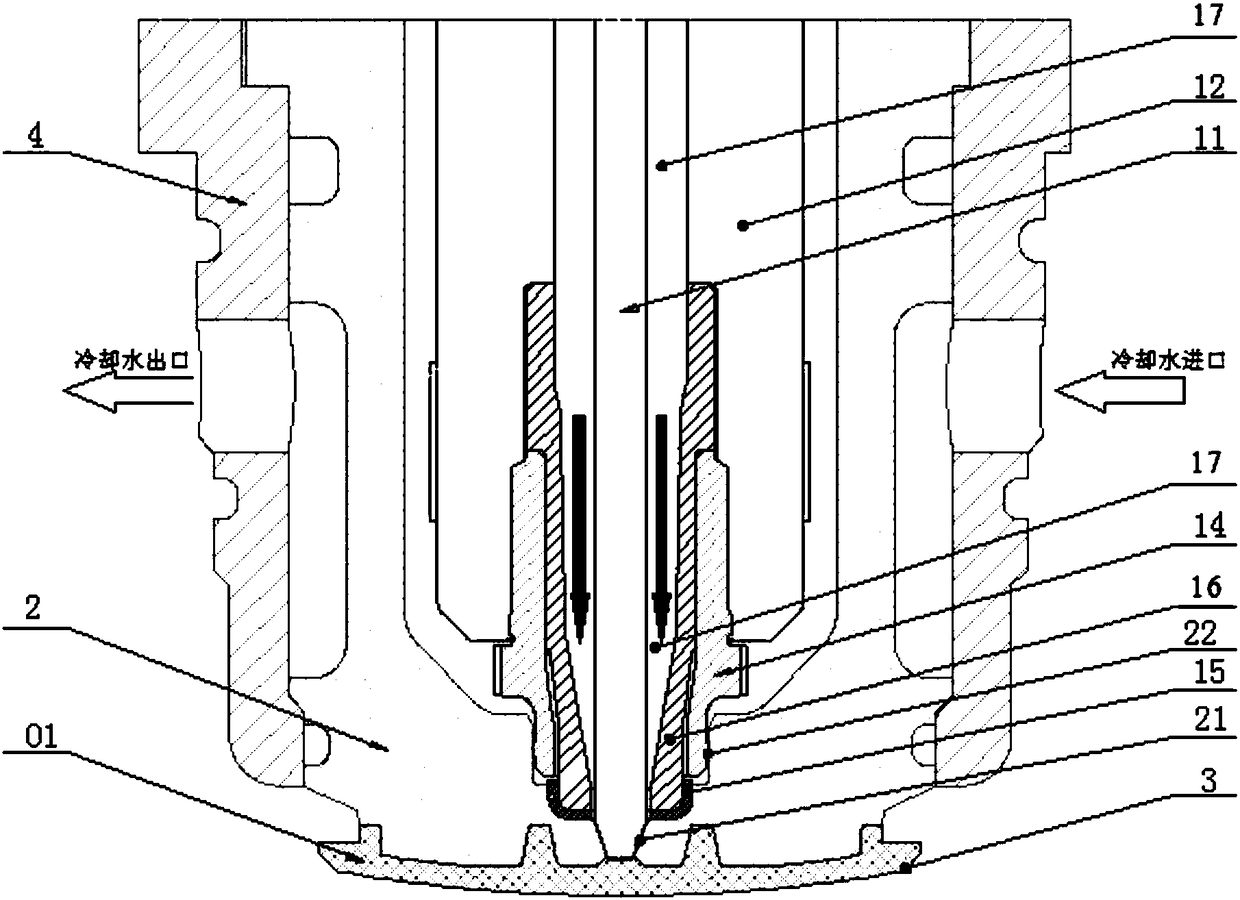

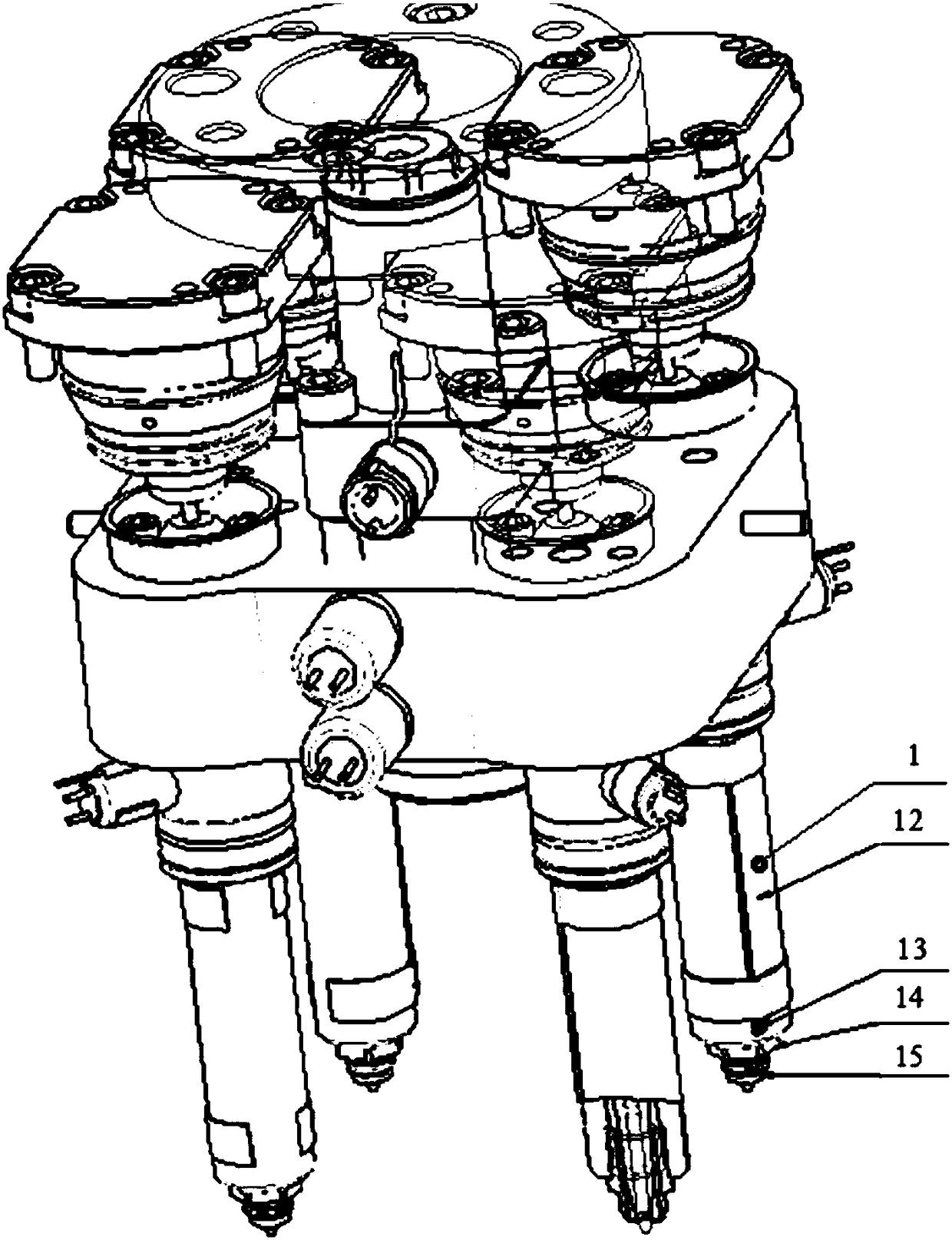

[0031] The present invention provides a Figure 1 ~ Figure 3 The ceramic product molding device shown is aimed at producing a round zirconia ceramic part with a relatively complex shape, concave-convex surface and thin-walled structure, which requires high precision and less machining.

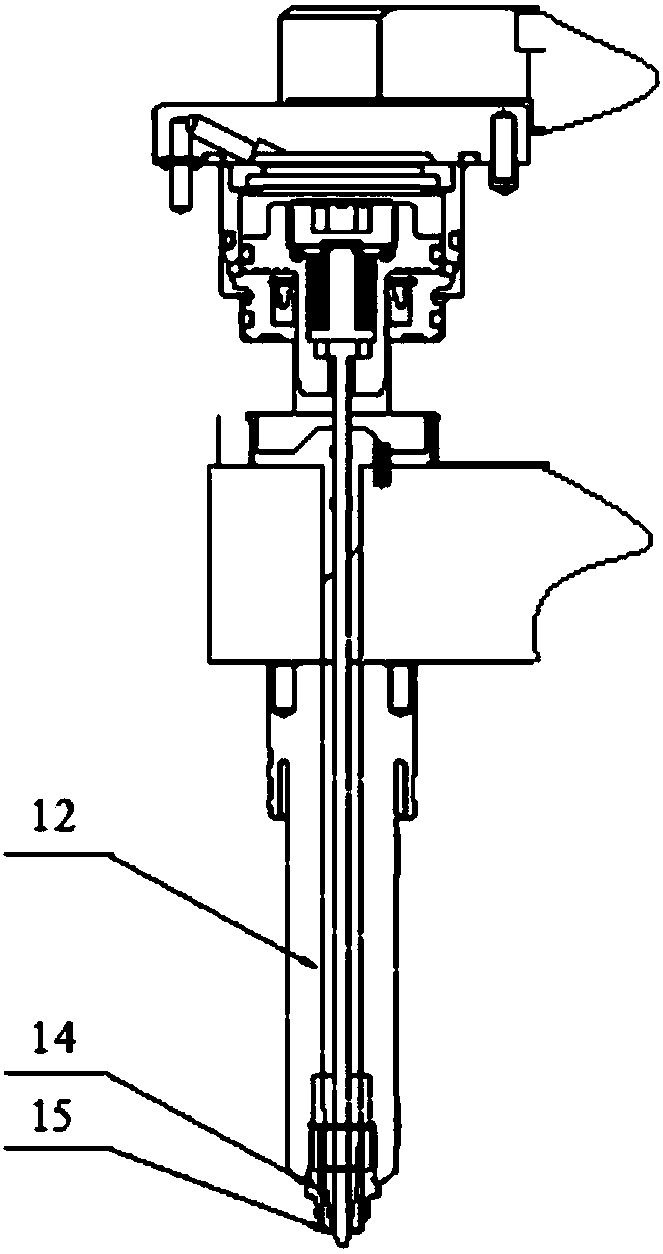

[0032]The present invention provides a molding device for ceramic products. The device includes a hot nozzle 1, a mold core insert 2, an upper mold and a lower mold. The hot nozzle includes a valve needle 11, a hot nozzle body 12, and is used The heating part 13, the titanium ring 14, the bakelite cap 15 and the high thermal conductivity ring 16 heated by the molding raw material, the thermal conductivity of the material used in the high thermal conductivity ring is greater than the thermal conductivity of the material used in the hot nozzle body; In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com