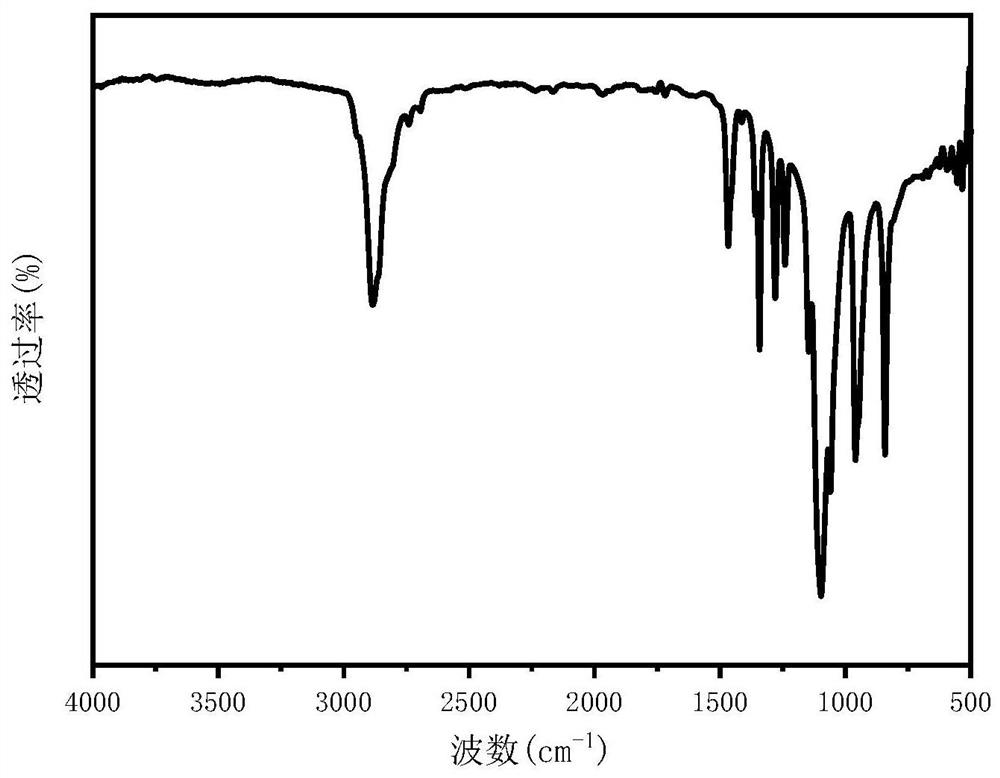

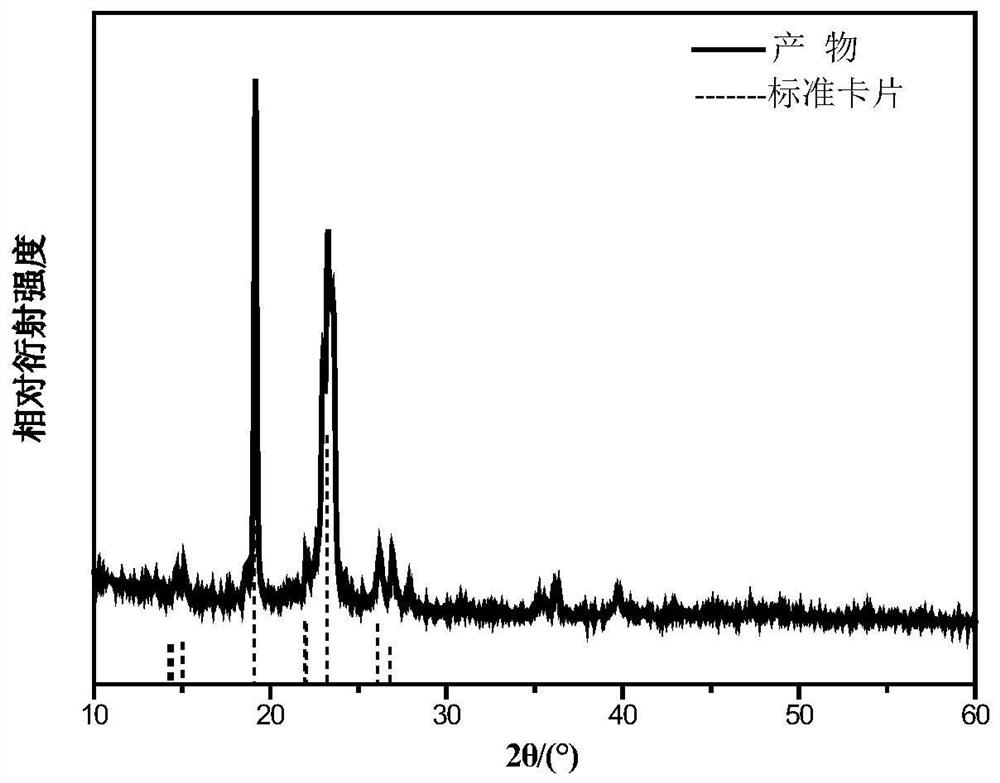

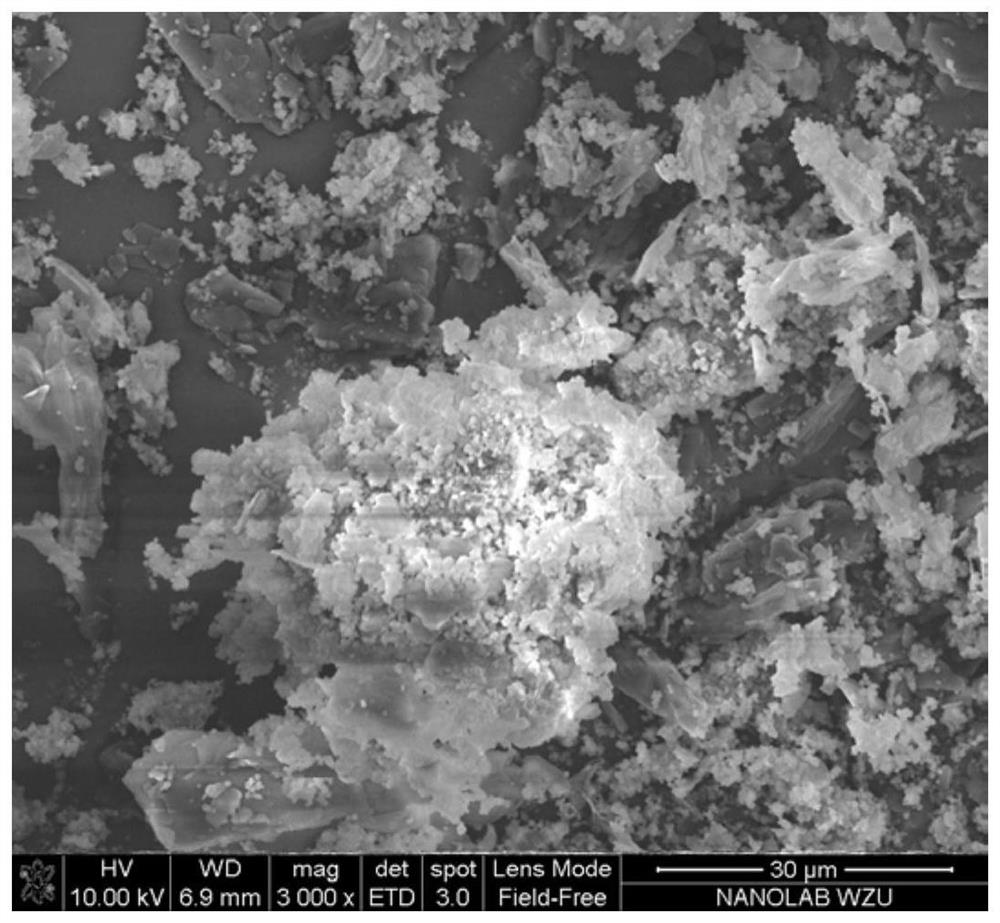

Preparation method of polyethylene glycol/silicon dioxide shape-fixed phase-change material

A technology of shape-setting phase change material and polyethylene glycol, which is applied in the field of phase change energy storage, can solve the problems of low thermal conductivity, low thermal conductivity, slow heat storage and release speed, etc., and achieves good thermal stability, high thermal conductivity, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Measure 60 milliliters of isopropanol (IPA) and 14 milliliters of deionized water and place them in a 100 milliliter round-bottomed flask, then weigh 5 grams of polyethylene glycol (PEG6000) and add them, at room temperature (25 ° C), rotating speed Under the condition of 500r / min, stir for 30 minutes, so that polyethylene glycol can be fully and rapidly dissolved in isopropanol and the volatilization of isopropanol should be minimized to form a uniform colorless and transparent mixed solution I.

[0037] Take 1mL of 3-aminopropyl-3-ethoxysilane ethanol solution (the volume ratio of 3-aminopropyl-3-ethoxysilane to ethanol is 1:19, ethanol is 99.5% analytically pure, and it is now prepared ) and 0.667mL of hydrochloric acid with a molar concentration of 0.2mol / L were mixed in a 50mL beaker, and then immediately added to the above mixed solution I, and stirred at room temperature (25°C) and at a speed of 500r / min After 6 minutes, mixed solution II was obtained.

[0038] ...

Embodiment 2

[0065] Measure 60 milliliters of isopropanol (IPA), 18 milliliters of deionized water to form a mixed solvent in a 100 milliliter round bottom flask, weigh 5 grams of polyethylene glycol (PEG6000) and join in the mixed solvent, at room temperature (18 ℃ ), stirring evenly for 30 minutes at a speed of 500r / min, so that the polyethylene glycol is fully and quickly dissolved in isopropanol and the volatilization of isopropanol is minimized to form a uniform colorless and transparent mixed solution I.

[0066]Take 1mL of 3-aminopropyl-3-ethoxysilane ethanol solution (the volume ratio of 3-aminopropyl-3-ethoxysilane to ethanol is 1:19, ethanol is 99.5% analytically pure, ready to use) Mix it with 0.667mL0.2mol / L hydrochloric acid in a 50mL beaker, then immediately add it to the above mixed solution I, and continue to stir evenly for 6 minutes at room temperature (18°C) at a speed of 500r / min to obtain a mixed Solution II.

[0067] Measure 0.25 ml (1.1 mmol) tetraethyl orthosilicat...

Embodiment 3

[0070] Measure 60 milliliters of isopropanol (IPA), 14 milliliters of deionized water in a 100 milliliter round-bottomed flask, weigh 3 grams of polyethylene glycol (PEG6000) and add it to the mixed solvent at room temperature (18° C.) Stir uniformly for 30 minutes under the condition of 500r / min, so that the polyethylene glycol is fully and quickly dissolved in isopropanol and the volatilization of isopropanol is minimized to form a uniform colorless and transparent mixed solution I.

[0071] Take 1mL of 3-aminopropyl-3-ethoxysilane ethanol solution (the volume ratio of 3-aminopropyl-3-ethoxysilane to ethanol is 1:19, ethanol is 99.5% analytically pure, ready to use) Mix it with 0.667mL0.2mol / L hydrochloric acid in a 50mL beaker, then immediately add it to the above mixed solution I, and continue to stir evenly for 6 minutes at room temperature (18°C) at a speed of 500r / min to obtain a mixed Solution II.

[0072] Measure 0.25 ml (1.1 mmol) tetraethyl orthosilicate (TEOS) int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com