A rotary feeder for solid polyolefin catalyst

A technology of polyolefin catalyst and rotary feeder, which is applied in the field of olefin polymerization, can solve problems such as residues, increased production costs, and unstable feeding, and achieves the effects of simple structure, low production costs, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

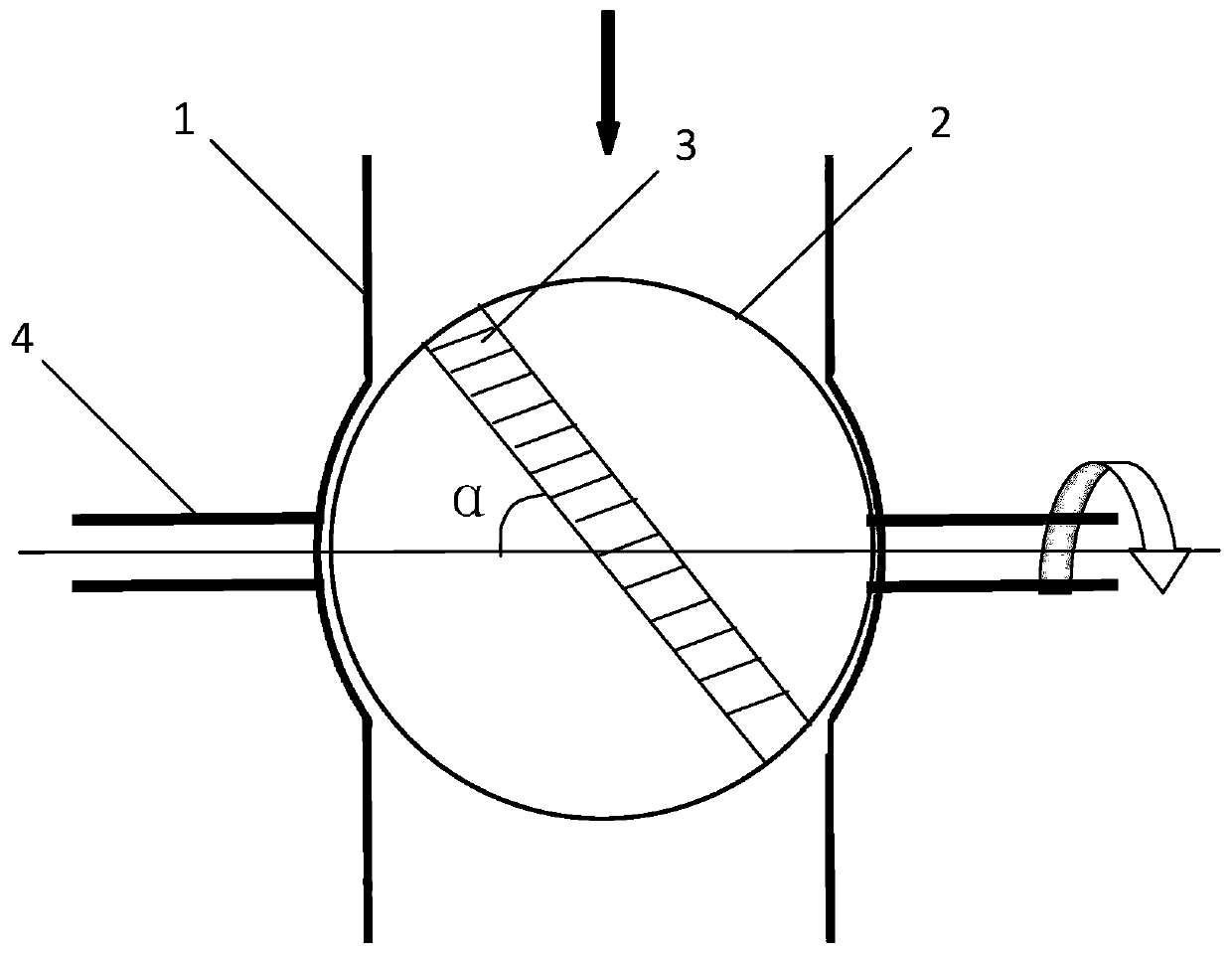

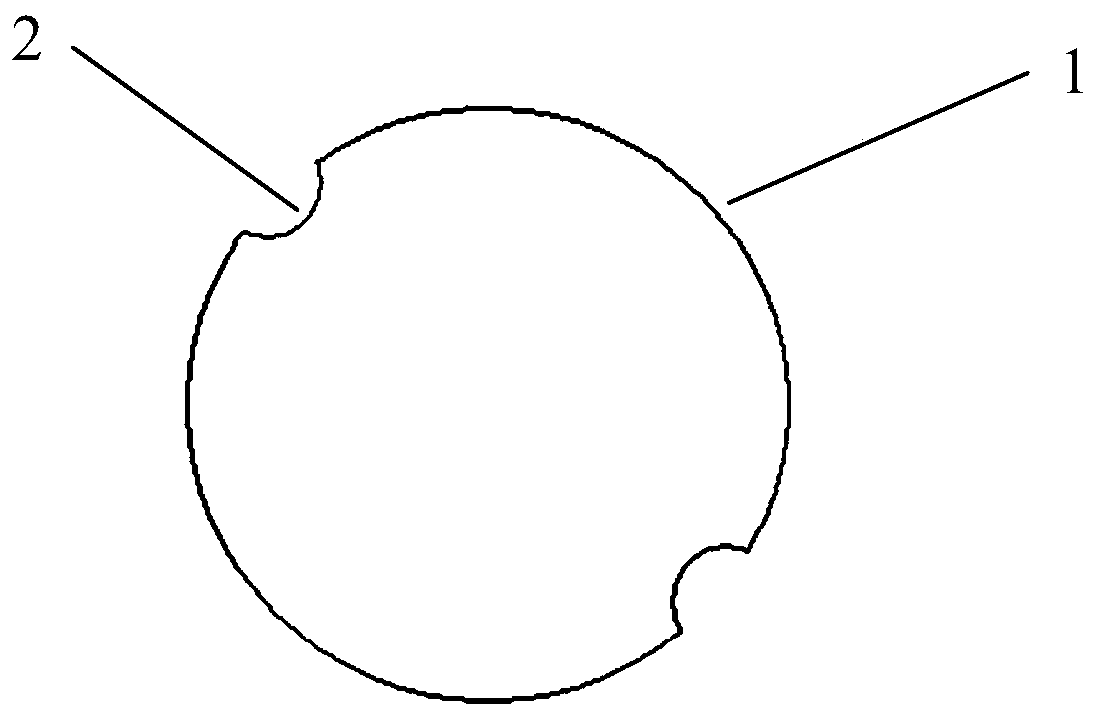

[0035] The angle α between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is determined to be 15°C, and the different rotation speeds of the spherical body 2 are accurately measured and calibrated with an invalid Ti-based catalyst. The specific process is to place the spherical body 2 The rotation speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm Min, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average, and then draw the The relationship curve between the amount of catalyst feed and the rotation speed of the spherical body 2, and determine its relationship formula. Obtain the relational curve or relational expression of this kind of catalyst feeding amount and spherical body 2 rotational speeds, determine that can by adjusting the rotating speed of spherical body 2, carry out accurate metering and control t...

Embodiment 2

[0037] The angle α between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is determined to be 20°C, and the different rotation speeds of the spherical body 2 are accurately measured and calibrated with an invalid Cr-based catalyst. The specific process is to place the spherical body 2 The rotation speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm Min, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average, and then draw the The relationship curve between the amount of catalyst feed and the rotation speed of the spherical body 2, and determine its relationship formula. Obtain the relationship curve or relational expression of this kind of catalyst feeding amount and spherical body 2 rotational speeds, confirm that can now by adjusting the rotating speed of spherical body 2, carry out accurate metering and contr...

Embodiment 3

[0039]The angle α between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is determined to be 30°C, and the different rotation speeds of the spherical body 2 are accurately measured and calibrated with an invalid metallocene catalyst. The specific process is that the spherical body 2 The rotation speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm Min, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average, and then draw the The relationship curve between the amount of catalyst feed and the rotation speed of the spherical body 2, and determine its relationship formula. Obtain the relationship curve or relational expression of this kind of catalyst feeding amount and spherical body 2 rotational speeds, confirm that can now by adjusting the rotating speed of spherical body 2, carry out accurate metering and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com