Extraction preparation process of high-purity vanadyl sulfate solution

A vanadyl sulfate solution and a preparation process technology, applied in liquid solution solvent extraction, solvent extraction, countercurrent extraction, etc., can solve the problems of low efficiency, high cost, complicated steps, etc., achieve simple operation process, low cost, and reduce impurities The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

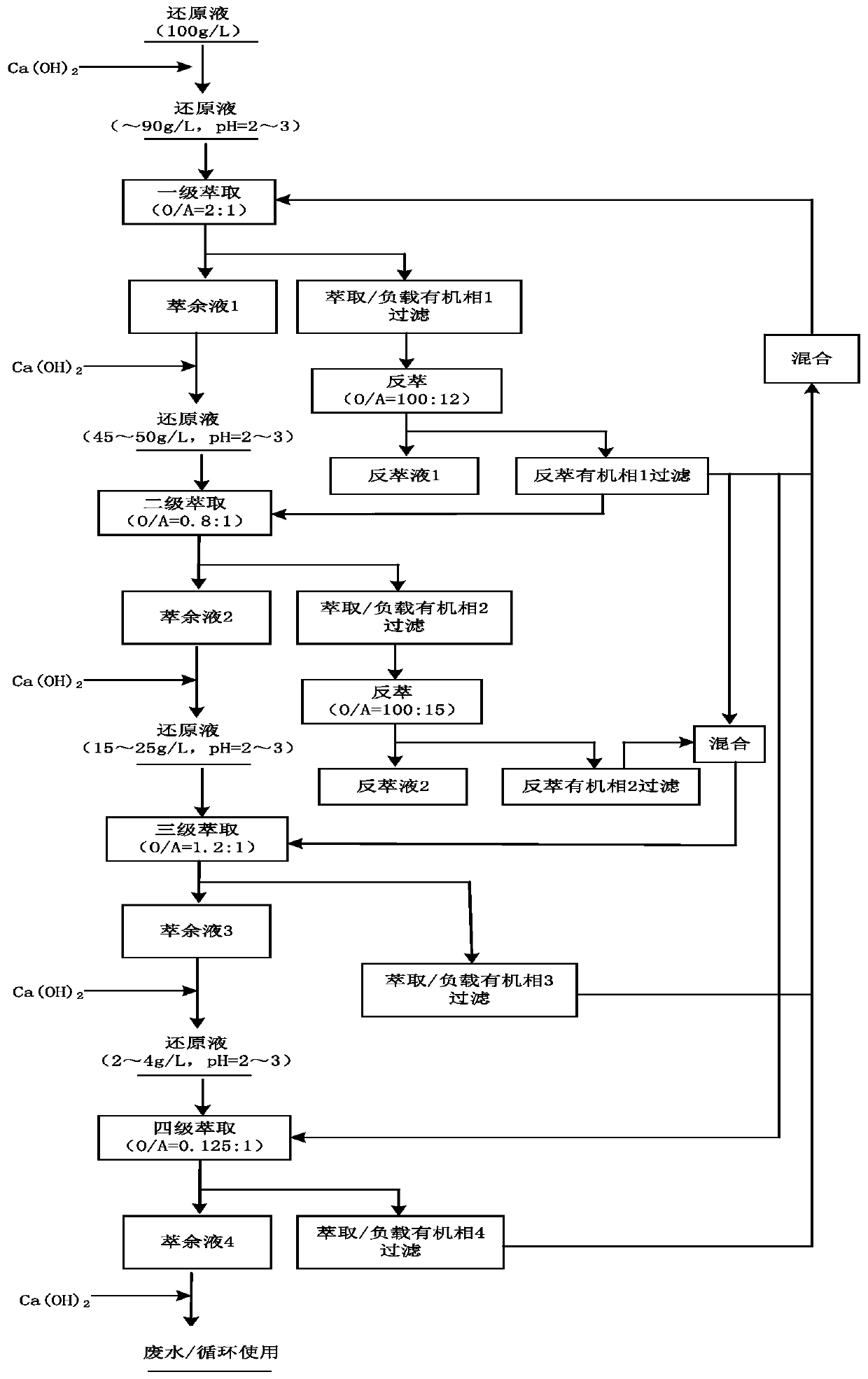

[0042] This embodiment discloses a process for the extraction and preparation of a high-purity vanadyl sulfate solution, such as figure 1 Specifically, the following steps are shown:

[0043]Step (1) Take 1 L of the reducing solution (vanadyl sulfate solution), adjust the pH to 2.35 with calcium hydroxide, and filter, wherein the V content is 87.14 g / L, the K content is 0.5341 g / L, the Na content is 0.8048 g / L, and the Cr content is 87.14 g / L. content of 0.0689g / L, Fe content of 0.1008g / L, Al content of 0.1490g / L, and Ca content of 0.5167g / L; it is mixed with 30% P204+70% sulfonated kerosene for extraction, and the extraction is compared to O / A=2:1, the extraction time is 5min, the two phases are separated to obtain the raffinate and the loaded organic phase; the loaded organic phase is filtered, and 4mol / L sulfuric acid is used for back extraction, and the back extraction ratio O / A=25:3, Obtain vanadyl sulfate solution and stripping organic phase, wherein V content 155.88g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com