Treatment system for tail gas of spray drying tower

A technology of spray drying tower and treatment system, which is applied in gas treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of heavy odor, large air volume of drying tower exhaust gas, and difficult treatment. To achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

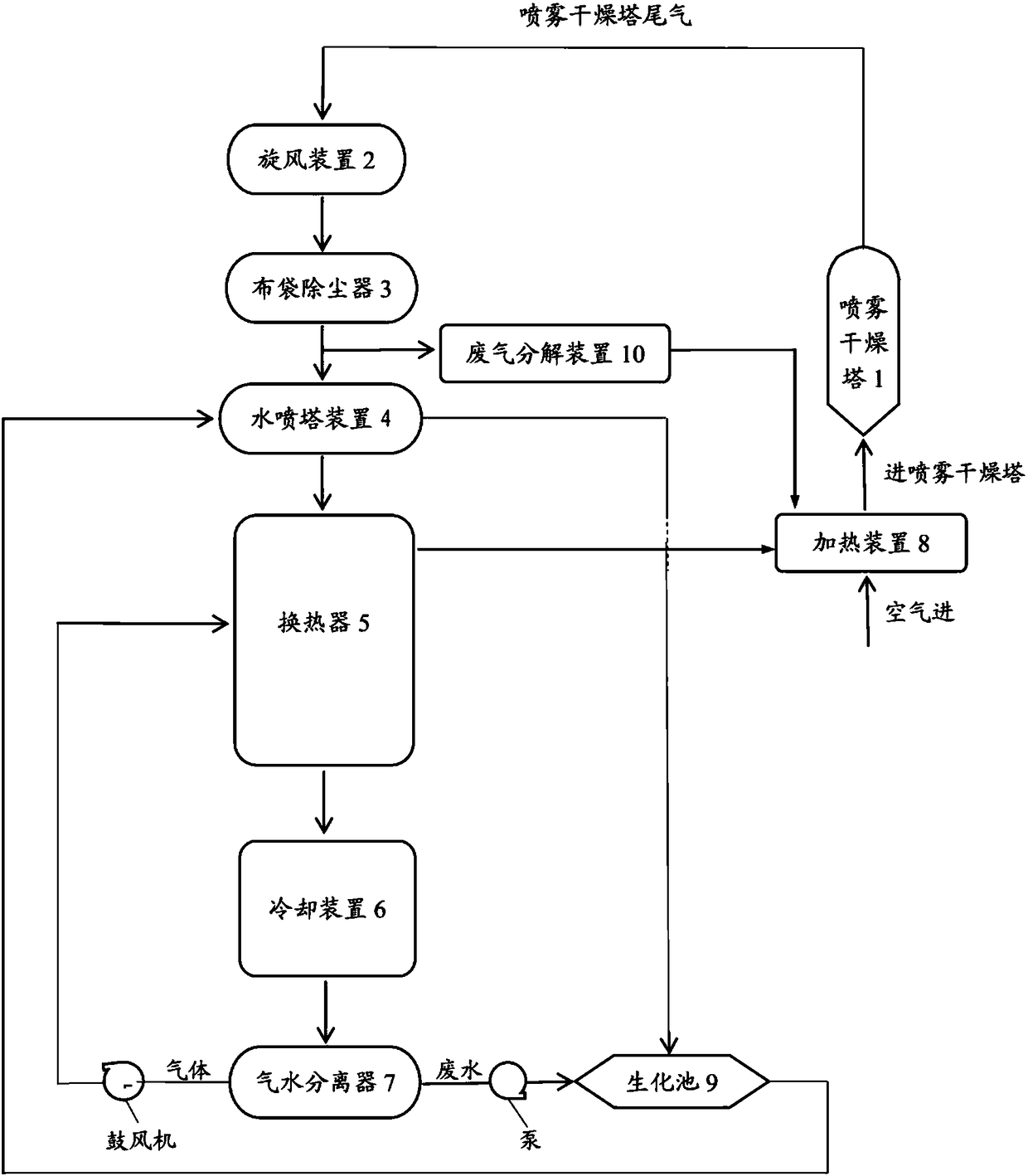

[0028] Such as figure 1 As shown, a treatment system for the tail gas of the spray drying tower is provided. The tail gas of the spray drying tower comes out from the spray drying tower 1, the temperature of the tail gas is 52°C, and the dust content is 10mg / M 3 , the dimensionless stench is 800.

[0029] The tail gas is processed by the cyclone device 2 and the bag dust removal device 3, and the dye products in the gas are recovered. The tail gas is divided into air flow I and air flow II (the flow rate of air flow I accounts for 10% of the total flow of tail gas), and the air flow I is treated by the waste gas decomposition device 10. After being heated to 103°C by the heating device 8, it returns to the spray drying tower 1. The waste gas decomposition device includes a water retainer, an electrostatic precipitator, a gaseous molecular resonance processor and an ultraviolet light machine connected in sequence. Detected, the dimensionless stench was 75.

[0030] The air fl...

Embodiment 2

[0033] Such as figure 1 As shown, a treatment system for the tail gas of the spray drying tower is provided. The tail gas of the spray drying tower comes out from the spray drying tower 1, the temperature of the tail gas is 60°C, and the dust content is 6mg / M 3 , the dimensionless stench is 1200.

[0034] The tail gas is processed by the cyclone device 2 and the bag dust removal device 3, and the dye products in the gas are recovered. The tail gas is divided into air flow I and air flow II (the flow rate of air flow I accounts for 35% of the total flow of tail gas). After being heated to 100°C by the heating device 8, it returns to the spray drying tower 1. The exhaust gas decomposition device includes a water retainer, an electrostatic precipitator, a gaseous molecular resonance processor and an ultraviolet light machine connected in sequence. After the airflow I is treated, the dust content is not Detected, dimensionless stench is 80.

[0035] The air flow II continues to ...

Embodiment 3

[0038] Such as figure 1 As shown, a treatment system for the tail gas of the spray drying tower is provided. The tail gas of the spray drying tower comes out from the spray drying tower 1, the temperature of the tail gas is 46°C, and the dust content is 16mg / M 3 , the dimensionless stench is 3500.

[0039] The tail gas is processed by the cyclone device 2 and the bag dust removal device 3, and the dye products in the gas are recovered. The tail gas is divided into air flow I and air flow II (the flow of air flow I accounts for 60% of the total flow of the tail gas). After the air flow I is treated by the waste gas decomposition device 10 After being heated to 103°C by the heating device 8, it returns to the spray drying tower 1. The waste gas decomposition device includes a water retainer, an electrostatic precipitator, a gaseous molecular resonance processor and an ultraviolet light machine. After the airflow I is treated, the dust content is not detected. Dimensionless sten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com