Copper target assembly and manufacturing method thereof

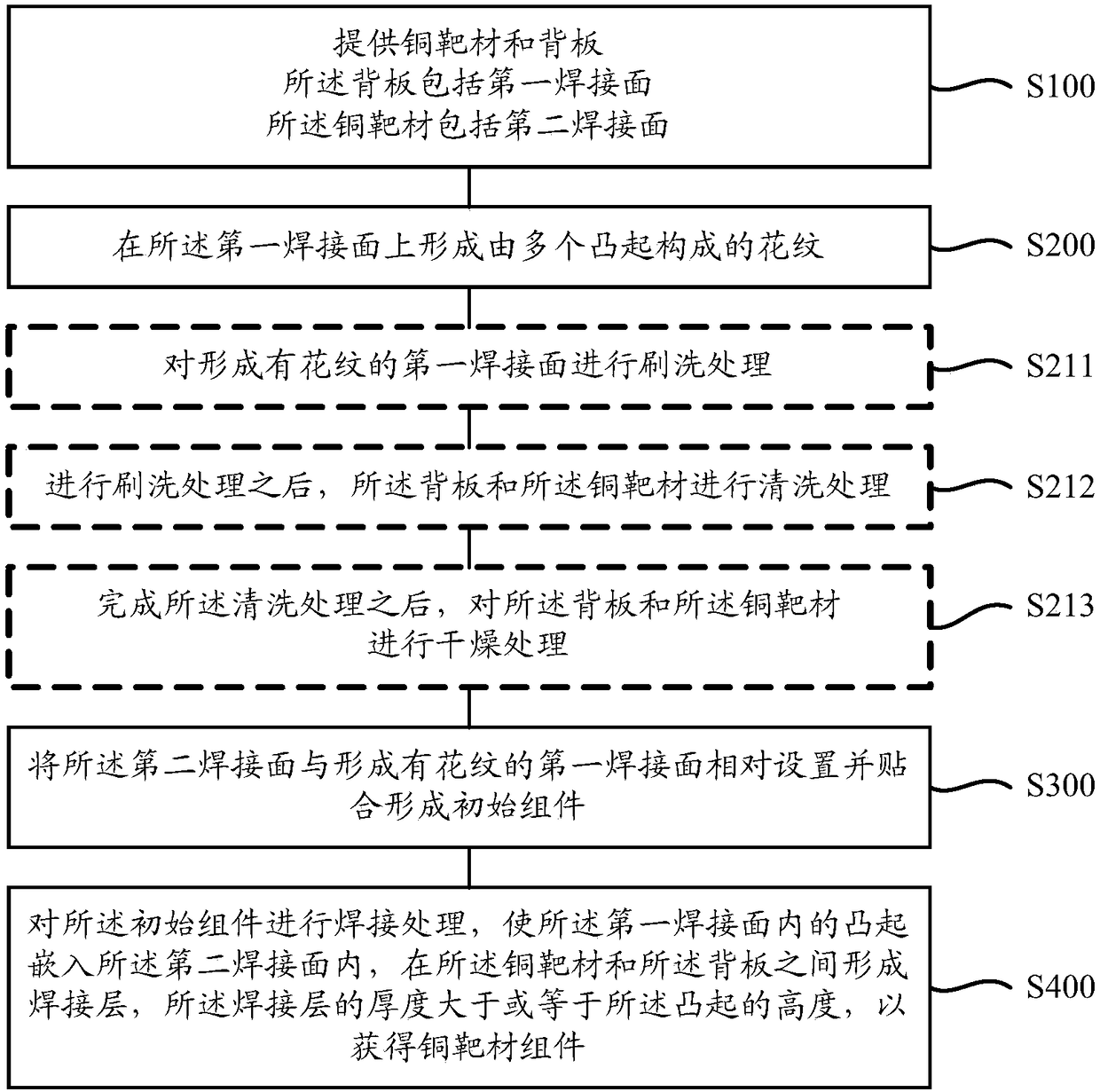

A manufacturing method and technology for copper targets, applied in the field of semiconductor manufacturing, can solve the problems of low hardness of high-purity copper targets, and the quality and performance of copper target components need to be improved, so as to improve the quality and performance, reduce the possibility of gaps, improve The effect of yield and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It can be seen from the background technology that the hardness of the copper target is low, and it needs to be welded with a high-hardness alloy back plate to form a copper target assembly before it can be used.

[0045] The copper target assembly is composed of high-purity copper target and alloy material back plate. The two need to be welded together during the manufacturing process. At present, the commonly used welding methods mainly include tin welding and diffusion welding.

[0046] For the copper target components manufactured by the soldering process, due to the low melting point of tin and poor high temperature resistance, when the temperature of the machine used for the copper target components is high, the phenomenon of solder melting is prone to occur, which is easy to increase the product risk of desoldering.

[0047] Diffusion welding is a high-temperature, high-strength welding method. However, if the temperature of diffusion welding is too high, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com