Steel fiber polystyrene particle regeneration thermal insulation concrete and preparation method thereof

A technology of polystyrene particles and thermal insulation concrete is applied in the field of building materials, which can solve the problems of low thermal conductivity, low fire resistance, low density, etc., and achieve the effects of enhanced crack resistance, reduced porosity, and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

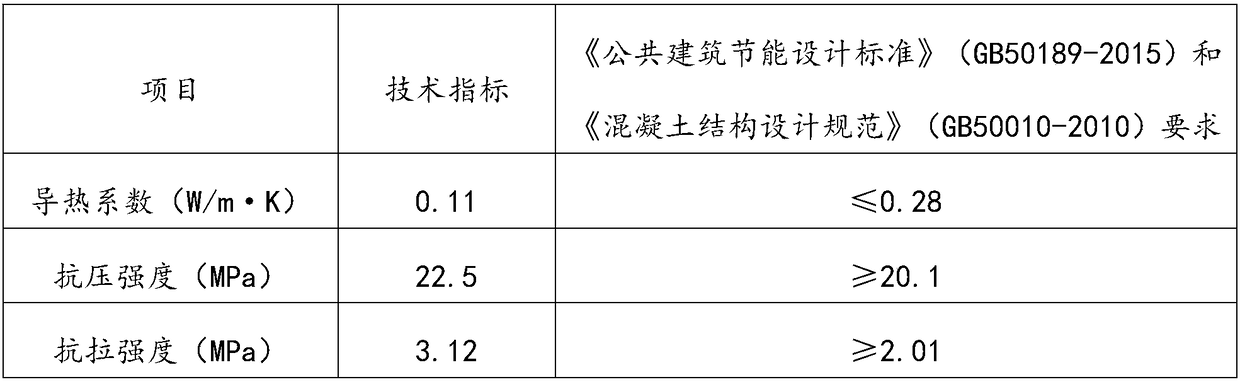

Embodiment 1

[0055] The steel fiber polystyrene particle regenerated thermal insulation concrete of this embodiment has a design strength of C30, and is made of the following raw materials in terms of the percentage of the total weight of the raw materials: 7% of water, 13.5% of cement, 30% of river sand, recycled coarse Aggregate 45.15%, resin rubber powder 1.5%, steel fiber 2%, water reducer 0.15% and polystyrene particles 0.7%. Wherein, the water is tap water; the strength grade of the cement is 42.5; the river sand is natural river sand with an apparent density of 2590kg / m 3 , water absorption rate 0.5%, fineness modulus 2.67; described regenerated coarse aggregate is to take the waste concrete whose strength is 30MPa-50MPa, after crushing and sieving, the particle size obtained is fragments of 5mm-20mm; the resin The rubber powder is a mixture of polyvinyl alcohol and vinyl acetate-ethylene carbonate copolymer, with a particle size of 400μm and a bulk density of 520kg / m 3 , the solid...

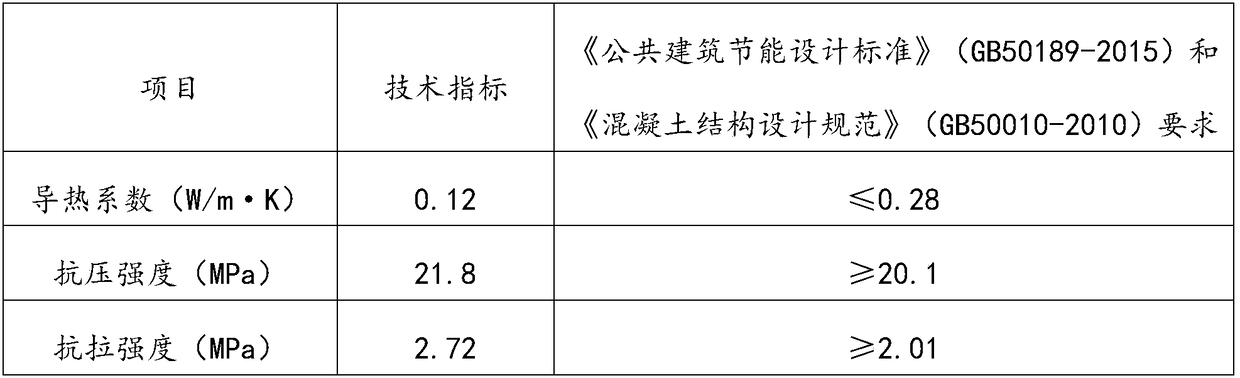

Embodiment 2

[0068] The steel fiber polystyrene particle regenerated thermal insulation concrete of this embodiment has a design strength of C30, and is made of the following raw materials according to the percentage of the total weight of the raw materials: 8% of water, 14% of cement, 32% of river sand, recycled coarse Aggregate 41%, resin rubber powder 2.5%, steel fiber 1.8%, water reducer 0.1% and polystyrene particles 0.6%. Wherein, the water is tap water; the strength grade of the cement is 42.5; the river sand is natural river sand with an apparent density of 2590kg / m 3 , water absorption rate 0.5%, fineness modulus 2.67; described regenerated coarse aggregate is to take the waste concrete whose strength is 30MPa-50MPa, after crushing and sieving, the particle size obtained is fragments of 5mm-20mm; the resin The rubber powder is a mixture of polyvinyl alcohol and vinyl acetate-ethylene carbonate copolymer, with a particle size of 400μm and a bulk density of 520kg / m 3 , the solid co...

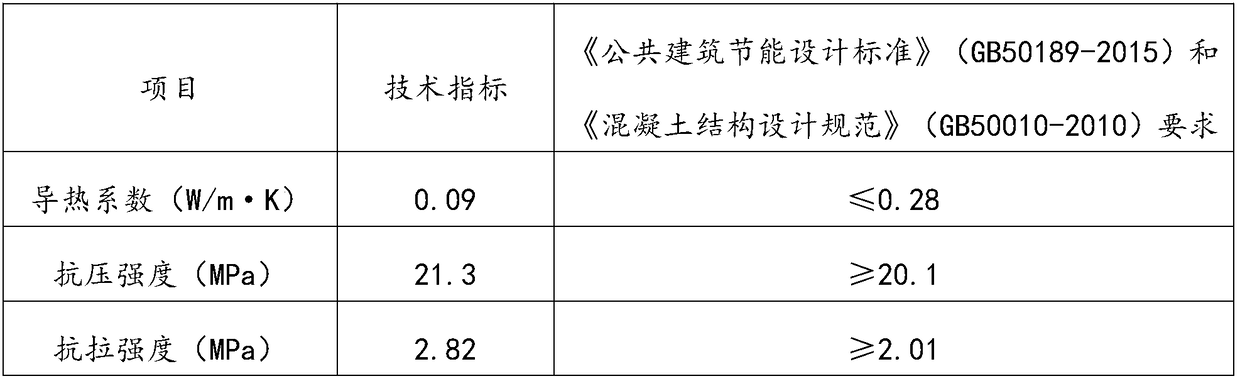

Embodiment 3

[0075] The steel fiber polystyrene particle regenerated thermal insulation concrete of this embodiment has a design strength of C30, and is made of the following raw materials in terms of the percentage of the total weight of the raw materials: 7% of water, 13.5% of cement, 30% of river sand, recycled coarse Aggregate 45.15%, resin rubber powder 1.5%, steel fiber 2%, water reducer 0.15% and polystyrene particles 0.7%. Wherein, the water is tap water; the strength grade of the cement is 42.5; the river sand is natural river sand with an apparent density of 2590kg / m 3 , water absorption rate 0.5%, fineness modulus 2.67; described regenerated coarse aggregate is to take the waste concrete whose strength is 30MPa-50MPa, after crushing and sieving, the particle size obtained is fragments of 5mm-20mm; the resin The rubber powder is a mixture of polyvinyl alcohol and vinyl acetate-ethylene carbonate copolymer, with a particle size of 400μm and a bulk density of 520kg / m 3 , the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com