Preparation method of 3-nitroso-2-phenyl-1H-indole

A nitroso and phenyl technology, applied in the field of organic chemical synthesis, can solve problems such as low yield, environmental pollution, and increased reaction risk coefficient, and achieve the effects of high yield, short synthesis process, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

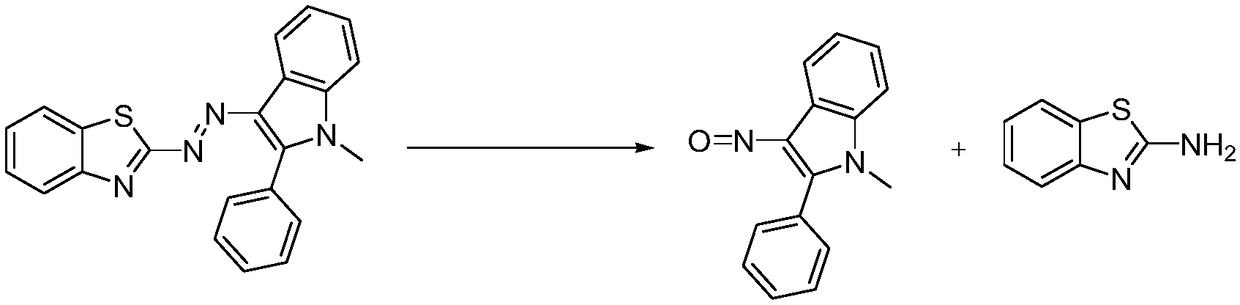

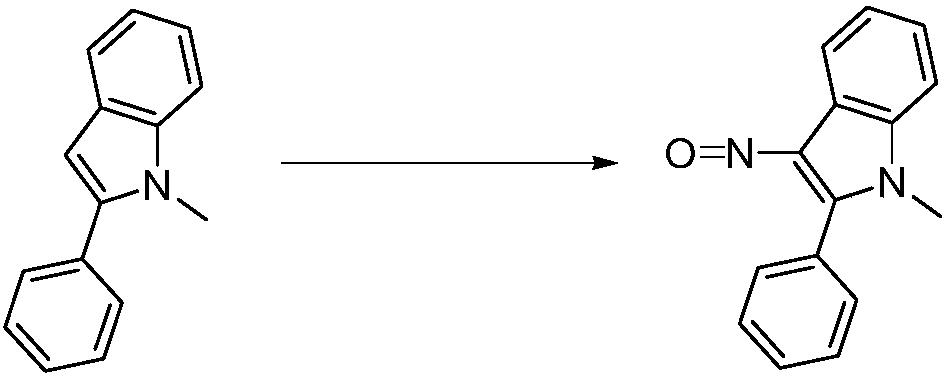

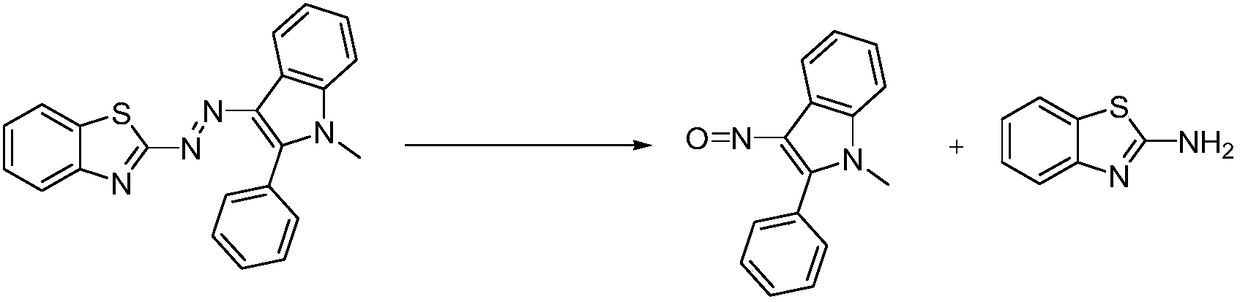

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of 3-nitroso-2-phenyl-1H-indole:

[0027] At 20ˉ30°C, tetrahydrofuran (500g) was added to a three-necked flask, and then 2-[2-(1-methyl-2-phenyl-1H-indol-3-yl)azo]benzothiazole ( 50g, 1.0eq) was added in the there-necked flask, stirred to dissolve completely; Potassium hydroxide (15.2g, 2.0eq) was added to 50g of water to prepare aqueous potassium hydroxide solution;

[0028] At 0°C, add potassium hydroxide aqueous solution dropwise to the reaction system in the three-necked flask, and after the dropwise addition, raise the temperature of the system to 50-60°C and react for 8ˉ10h. After the reaction is over, cool down the reaction system to 0-10°C;

[0029] Slowly add 10% dilute hydrochloric acid dropwise to the above reaction system, adjust the pH value of the system to 1-2, separate the organic phase, extract the product with methyl tert-butyl ether (500g) in the water phase, combine the organic phase, add water (250g) and stir to wash Organic p...

Embodiment example 2

[0031] A preparation method of 3-nitroso-2-phenyl-1H-indole:

[0032] At 20ˉ30°C, tetrahydrofuran (500g) was added to a three-necked flask, and then 2-[2-(1-methyl-2-phenyl-1H-indol-3-yl)azo]benzothiazole ( 50g, 1.0eq) was added in the there-necked flask, stirred to dissolve completely; sodium hydroxide (10.9g, 2.0eq) was added to 50g of water to prepare aqueous sodium hydroxide solution;

[0033] At 0°C, add the sodium hydroxide aqueous solution dropwise to the reaction system in the three-necked flask. After the dropwise addition, raise the temperature of the system to 50-60°C and react for 8ˉ10h. After the reaction is over, cool down the reaction system to 0-10°C;

[0034] Slowly add 10% dilute hydrochloric acid dropwise to the above reaction system, adjust the pH value of the system to 1-2, separate the organic phase, extract the product with methyl tert-butyl ether (500g) in the water phase, combine the organic phase, add water (250g) and stir to wash Organic phase, liq...

Embodiment example 3

[0036] At 20ˉ30°C, acetonitrile (500g) was added to a three-necked flask, and then 2-[2-(1-methyl-2-phenyl-1H-indol-3-yl)azo]benzothiazole ( 50g, 1.0eq) was added in the there-necked flask, stirred to dissolve completely; Potassium hydroxide (15.2g, 2.0eq) was added to 50g of water to prepare aqueous potassium hydroxide solution;

[0037] At 0°C, add potassium hydroxide aqueous solution dropwise to the reaction system in the three-necked flask, and after the dropwise addition, raise the temperature of the system to 50-60°C and react for 8ˉ10h. After the reaction is over, cool down the reaction system to 0-10°C;

[0038] Slowly add 10% dilute hydrochloric acid dropwise to the above reaction system, adjust the pH value of the system to 1-2, separate the organic phase, extract the product with methyl tert-butyl ether (500g) in the water phase, combine the organic phase, add water (250g) and stir to wash Organic phase, liquid separation, add anhydrous sodium sulfate (100g) to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com