Organic silicon resin as well as preparation method and application thereof

A silicone and resin technology, applied in the field of silicone resin and its preparation, can solve the problems of affecting the release agent performance of the silicone resin, affecting the performance of the silicone resin, high viscosity of the silicone resin, etc., and achieving fast light curing speed. , Improve performance, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

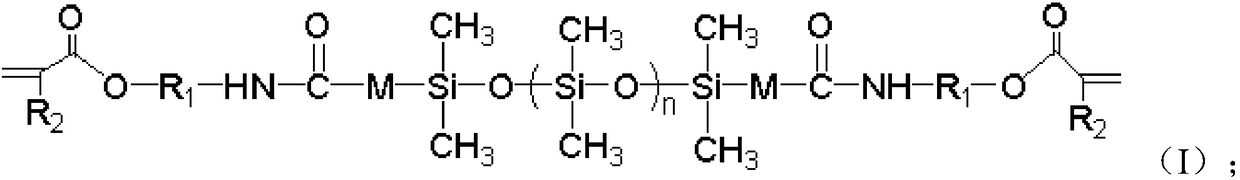

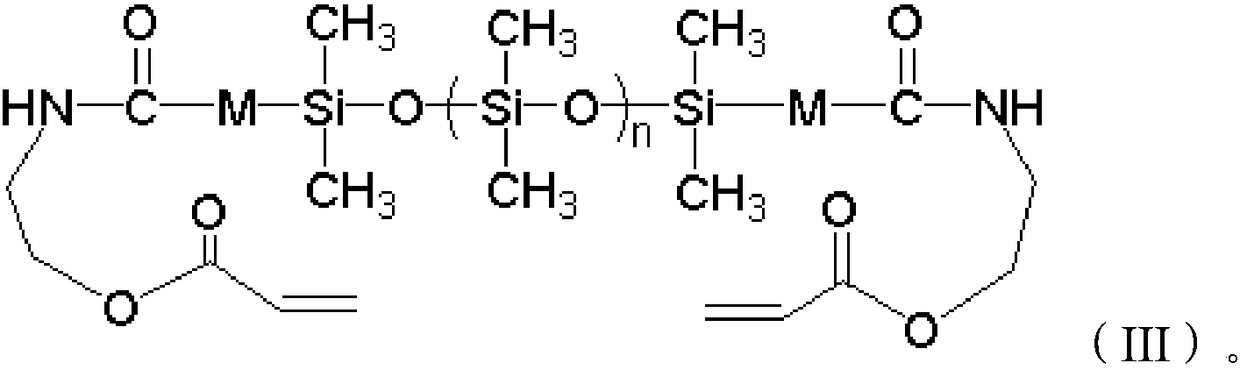

[0065] In the second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned silicone resin, which specifically includes the following steps:

[0066] Step 1, preparing polyether-modified silicone oil with a structure shown in formula (V);

[0067]

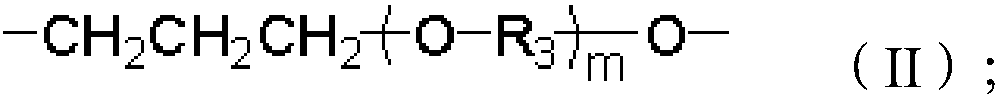

[0068] Wherein, n≥50, the structure of M is as shown in formula (II):

[0069]

[0070] Among them, m≥1, R 3 is an alkylene group;

[0071] Step 2, reacting the polyether-modified silicone oil obtained in step 1 with a compound having a structure shown in formula (VI) to obtain a silicone resin shown in formula (I);

[0072]

[0073] Among them, R 1 is an alkylene group, R 2 is hydrogen or methyl.

[0074] In the preparation method provided in the embodiment of the present invention, the silicone resin represented by formula (I) is prepared from polyether-modified silicone oil and a compound having a structure represented by formula (VI) as raw materials. Wherein, in the co...

Embodiment 1

[0106] This embodiment provides a silicone resin having a structure shown in formula (X), the preparation method of the silicone resin is as follows:

[0107] Step 101, add 5g of tetramethyldihydrodisiloxane (HMM, purchased from Dow Corning (Zhangjiagang) Silicone Co., Ltd., the same below) and 750g of octamethylcyclotetrasiloxane (D4 , purchased from Dow Corning (Zhangjiagang) Silicone Co., Ltd., the same below), and 37.75 g of amberlyst-35 solid acid catalyst (produced by Rohm and Haas Company, the same below) was added. The temperature was raised to 30°C for 12h. After the reaction finishes, remove the solid acid catalyst by filtration, and then add 0.5% NaHCO that accounts for the total mass of the filtrate in the resulting filtrate. 3 Neutralizes residual free acids. Afterwards, the unreacted D4 was distilled and extracted under the conditions of pressure -0.1MPa and temperature 130°C to obtain a clear and transparent hydrogen-terminated silicone oil represented by form...

Embodiment 2

[0116] This embodiment provides a silicone resin having a structure shown in formula (X), the preparation method of the silicone resin is as follows:

[0117] Step 201, prepare hydrogen-terminated silicone oil according to the method in step 101 in Example 1.

[0118] In step 202, weigh 100 g of the hydrogen-terminated silicone oil prepared in step 201, and add allyl polyether F6 (produced by Haian Petrochemical in Jiangsu Province, with a hydroxyl value of 45±8 mgKOH / g, the structure is shown in formula (XII), the same below ); Calculate the molar number of silicon-hydrogen bonds in the hydrogen-terminated silicone oil according to the measured hydrogen content, and the molar ratio of the silicon-hydrogen bonds in the allyl polyether F6 and the hydrogen-terminated silicone oil is 1.4:1.

[0119]

[0120] Then the temperature was raised to 100° C. under a nitrogen atmosphere, and then 10 ppm chloroplatinic acid solution in isopropanol was added to the reaction system, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com