Tail vegetable utilization technology applicable to large biogas project

A tail vegetable and biogas technology, which is applied in the energy field, can solve the problems of high water content of tail vegetable, environmental pollution, and less research on the ratio of industrial large-scale biogas raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

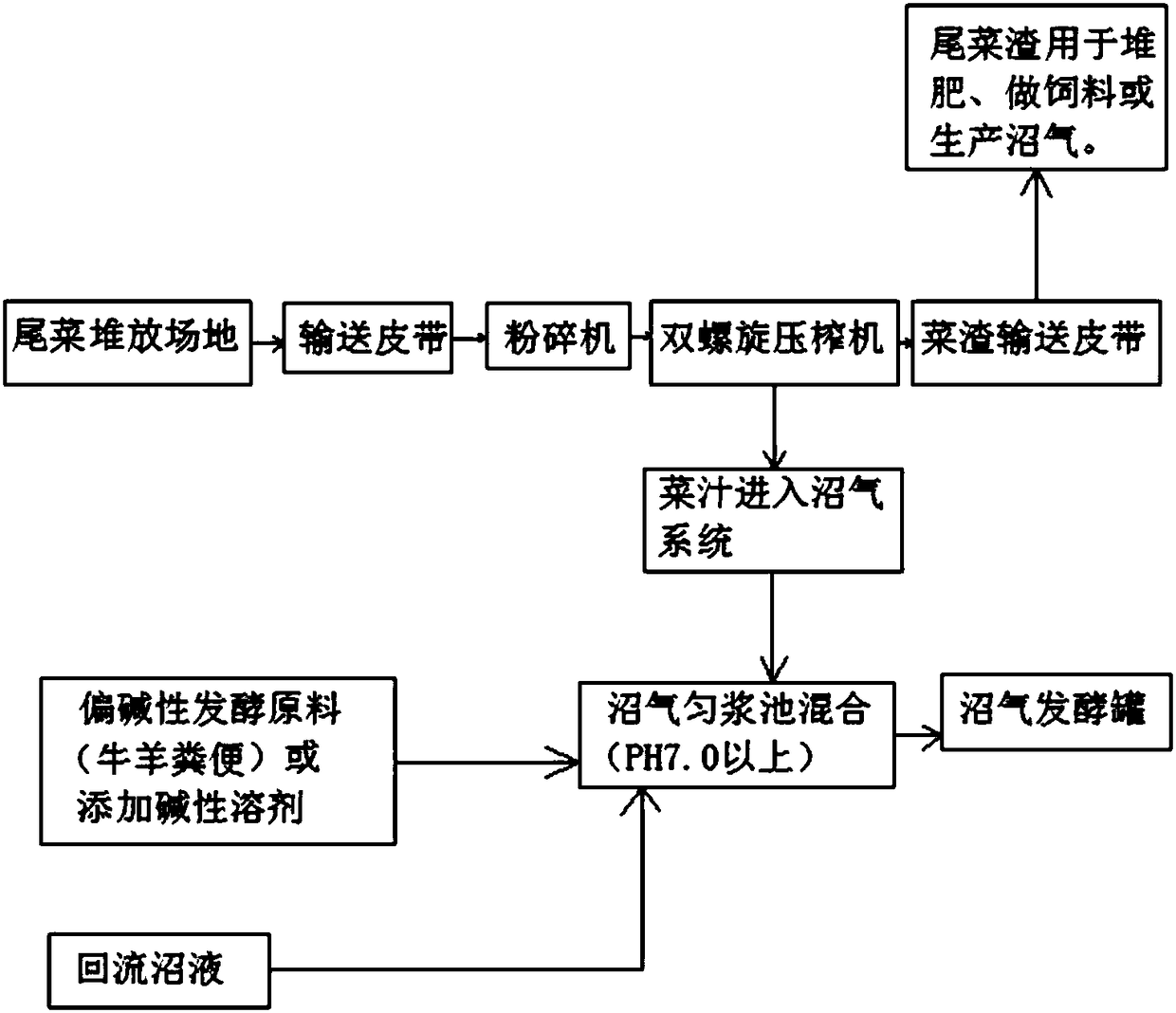

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] see as figure 1 Shown, the technical scheme that this specific embodiment adopts is: its operating steps are as follows:

[0024] 1. Crushing and pressing of tail vegetables:

[0025] 1.1. Use a large hammer mill to crush the tail vegetables sent by vegetable processing enterprises into powder or paste materials to increase their fluidity;

[0026] 1.2. Send the pulverized tail vegetable raw materials into a screw press for extrusion, so that the vegetable dregs and vegetable juice are fully separated, and at the same time, the cellulose of the vegetable is further destroyed;

[0027] 2. Biogas generation:

[0028] The tail vegetable juice obtained after pressing flows into the homogenization tank of the biogas digester by itself, and is mixed with the biogas slurry and livestock manure returned from the anaerobic tank, and the carbon-nitrogen ratio of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com