Production method of toughness nodular cast iron

A technology of ductile iron and a production method, applied in the field of foundry processing, can solve the problems of low forming efficiency, high production cost, reducing the carbon and silicon equivalent of cast iron, etc., and achieves improved fatigue resistance and wear resistance, improved structural strength and toughness, The effect of reducing internal stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

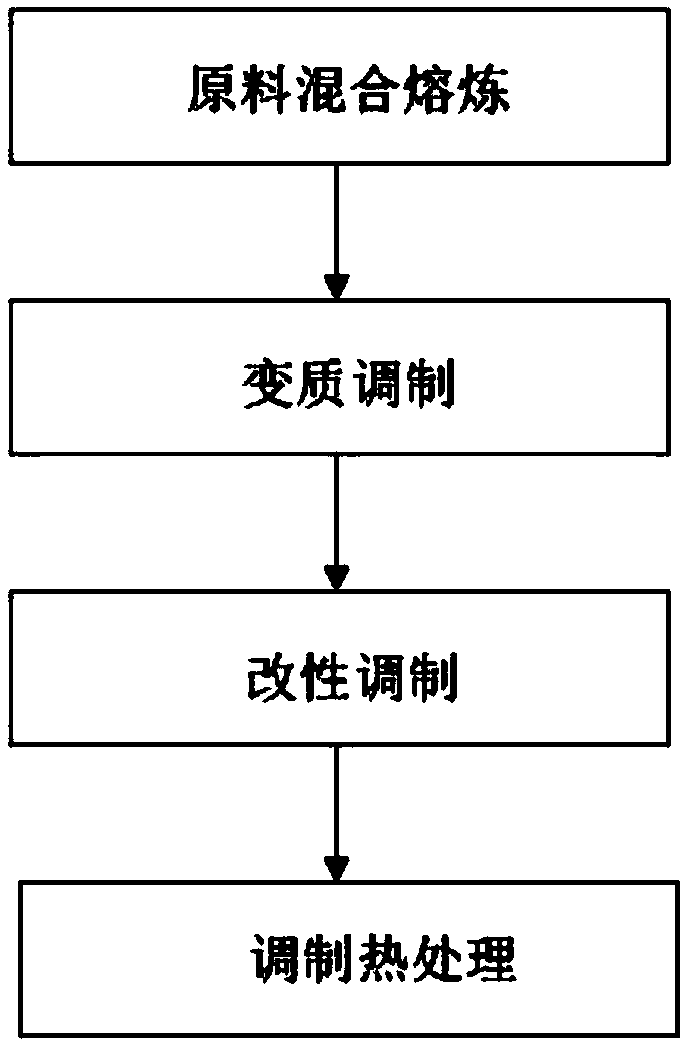

[0021] like figure 1 Shown is a production method of toughness ductile iron, comprising the following steps:

[0022] The first step is to mix and smelt the raw materials. First, steel scrap, returned gray iron, ferrosilicon alloy, ferromanganese alloy and ferrotitanium alloy are added to the melting furnace in proportion, of which 15% is returned gray iron, 3% is ferrosilicon alloy, 5% is ferromanganese alloy, 4% ferro-titanium alloy, the rest is scrap steel, then the air in the melting furnace is discharged by argon gas and the air pressure in the melting furnace is kept constant at 3 standard atmospheric pressures, and then the melting furnace is heated to 1450°C until the raw materials in the melting furnace are all After the molten metal is stirred evenly in the molten state, the molten metal sample is taken from the furnace for composition gap analysis, and the content of the molten metal in the furnace is adjusted according to the composition analysis results. for 40 m...

Embodiment 2

[0031] like figure 1 Shown is a production method of toughness ductile iron, comprising the following steps:

[0032] The first step is to mix and smelt the raw materials. First, steel scrap, returned gray iron, ferrosilicon alloy, ferromanganese alloy and ferrotitanium alloy are added to the melting furnace in proportion, of which 15% is returned gray iron, 9% is ferrosilicon alloy, 4% is ferromanganese alloy, Titanium-iron alloy 3.5%, the rest is scrap steel, then the air in the melting furnace is discharged by argon gas and the air pressure in the melting furnace is kept constant at 1.5 standard atmospheres, and then the melting furnace is heated to 1550 °C until the raw materials in the melting furnace are all After the molten metal is stirred evenly in the molten state, the molten metal sample is taken from the furnace for composition gap analysis, and the content of the molten metal in the furnace is adjusted according to the composition analysis results. 15 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com