Annular cutting alloy tooth for drilling tool

A technology for cutting alloys and rings, applied in the field of ring-shaped cutting alloy teeth for drilling and mining tools, can solve the problems of short cutting edges, low service life, falling off of cemented carbide teeth, etc., achieve uniform stress and wear, and improve the use of Longevity, the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the drawings:

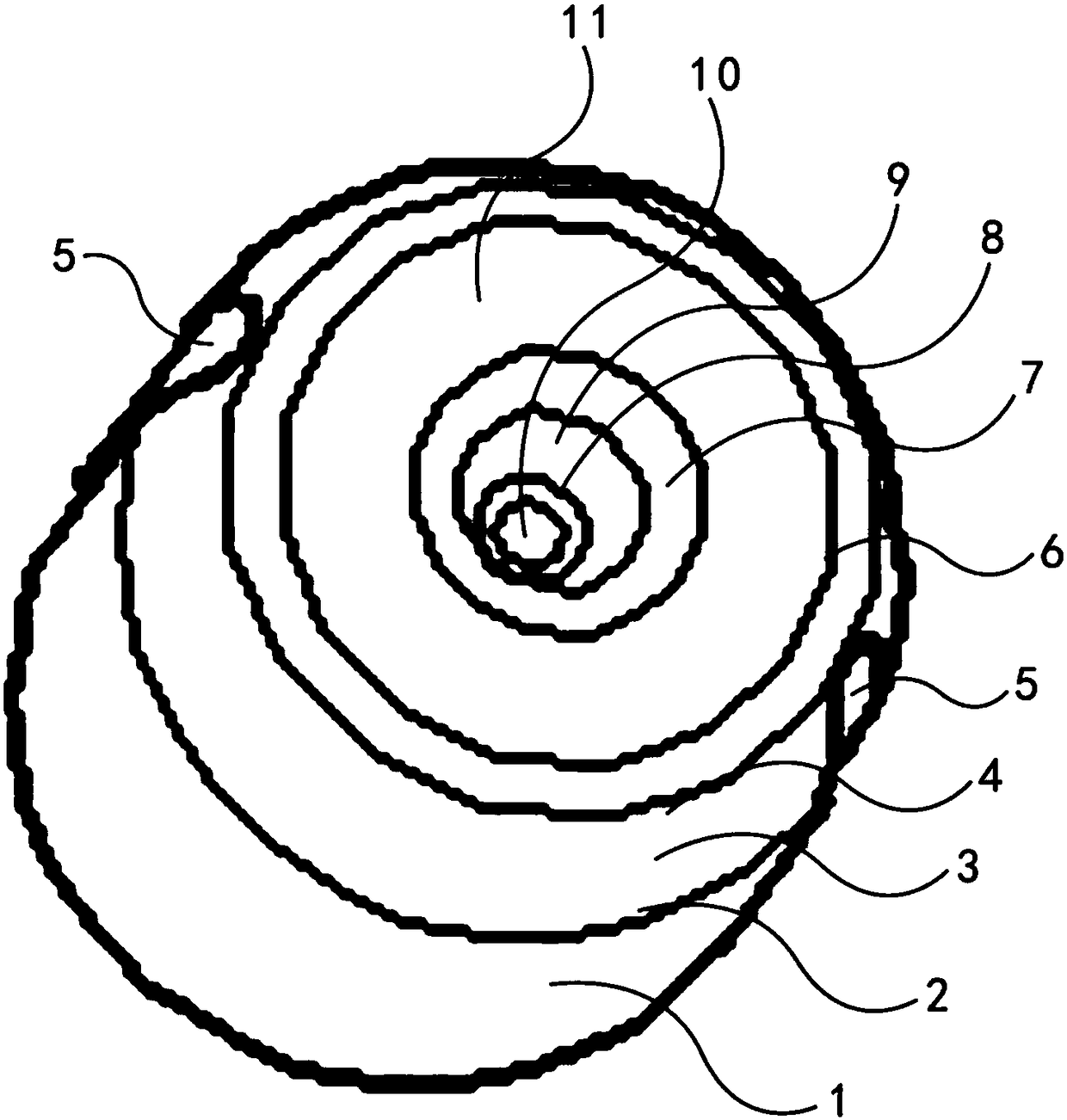

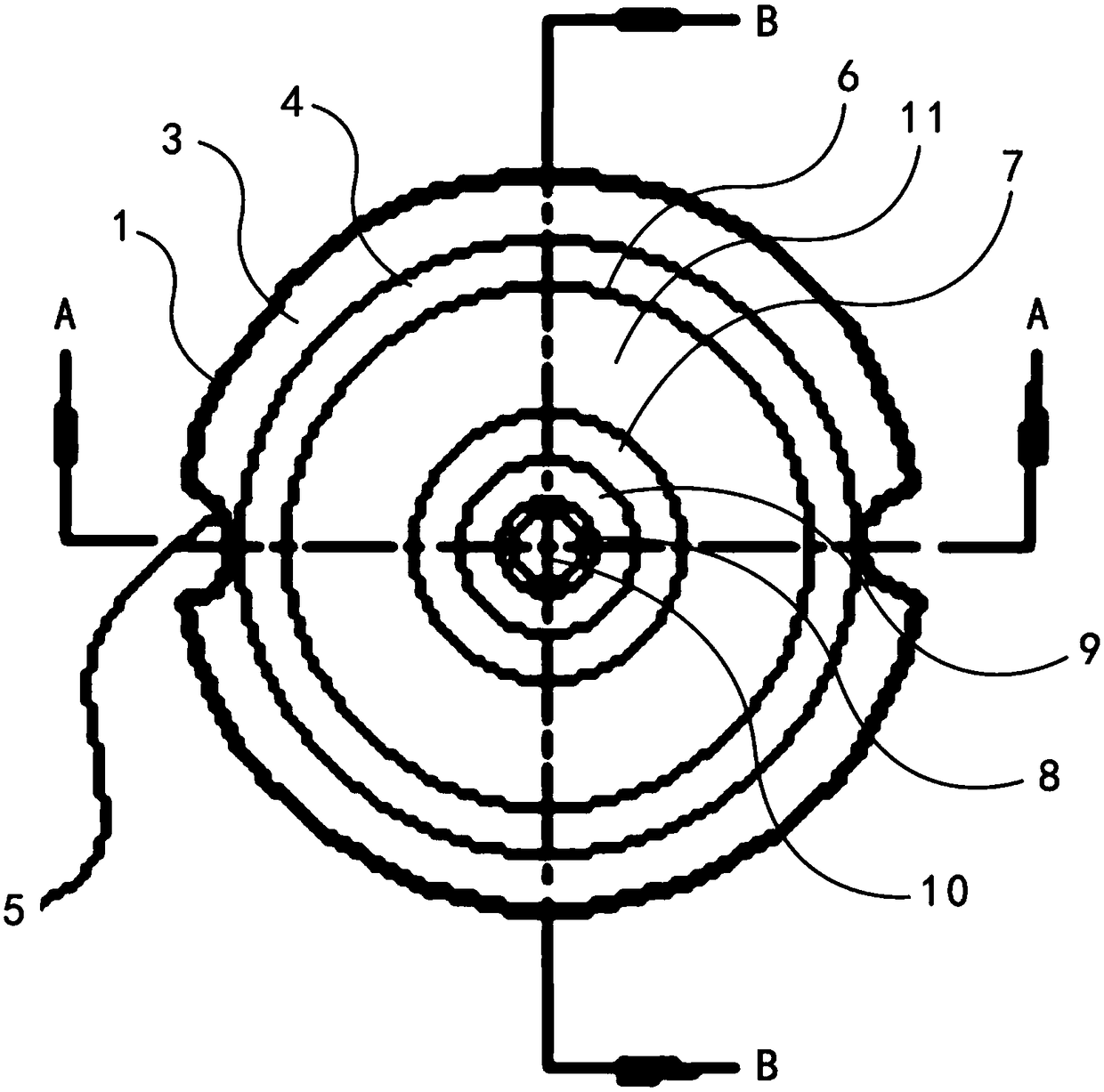

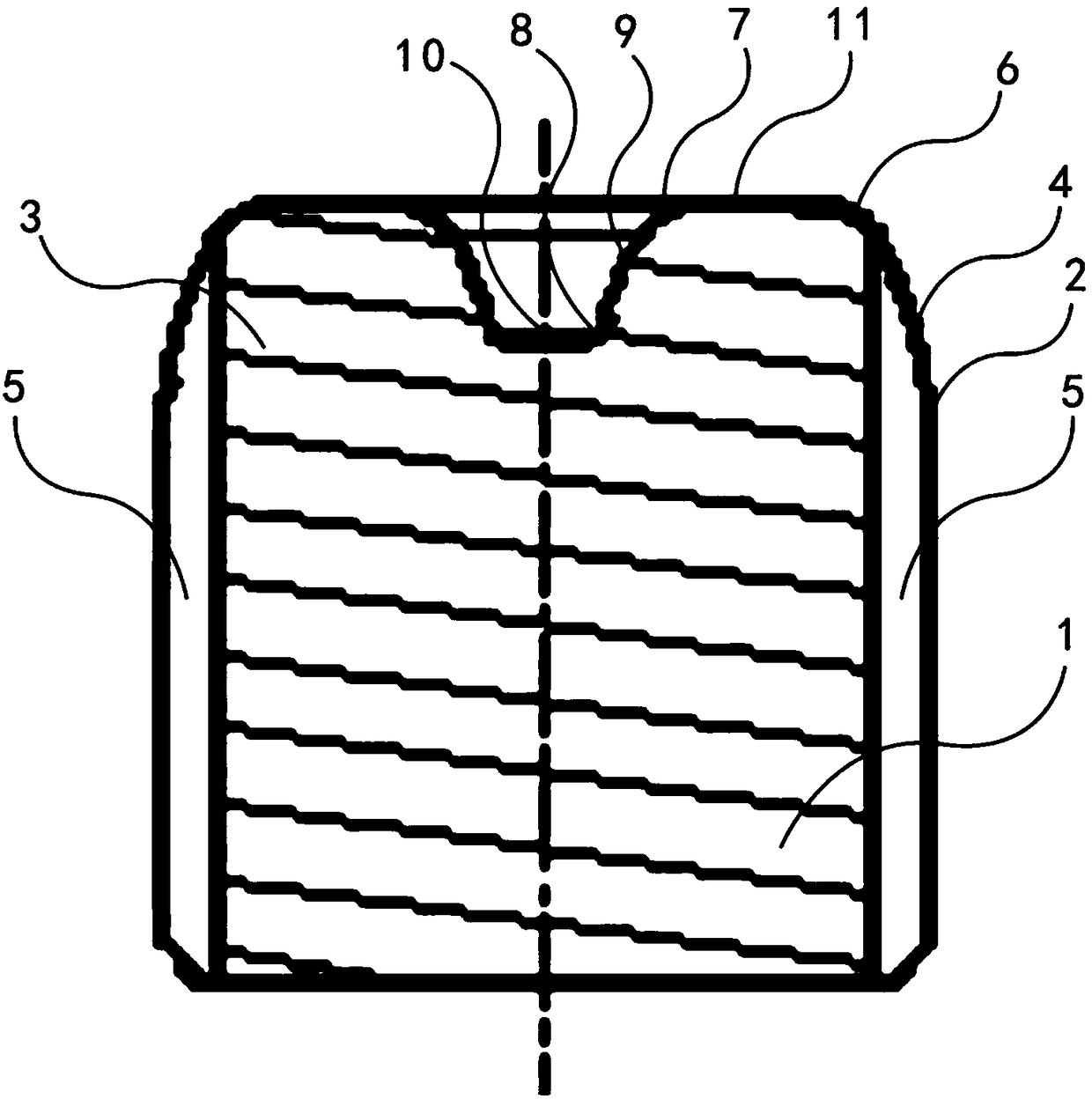

[0024] Such as Figure 1-Figure 4 As shown, the annular cutting alloy teeth for drilling tools of the present invention are cemented carbide teeth or cemented carbide composite teeth, including an integrally formed tooth body 1 and a tooth crown 3. The tooth body 1 is a cylinder or is centered on a central axis. It is a polygonal cylinder with the axis of symmetry. In this example, it is a cylinder. Assuming that the central axis of the tooth body 1 is vertical, the tooth crown 3 is located directly above the tooth body 1, and the diameter of the outer circumferential surface of the tooth crown 1 increases from the bottom. The top is gradually reduced to the top, and the center of the top of the crown 3 is concave to form a central counterbore (not marked in the figure). The central counterbore is a blind hole or a through hole. If it is a blind hole, its depth is not less than the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com