Application of konjac glucomannan to bonding agent

A konjac glucomannan and binder technology, which is applied to structural parts, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as capacity decay, viscosity, unattainable mechanical properties, and electrode structure powdering and falling off. , to prolong the cycle life, enhance the structural stability, and resist expansion and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

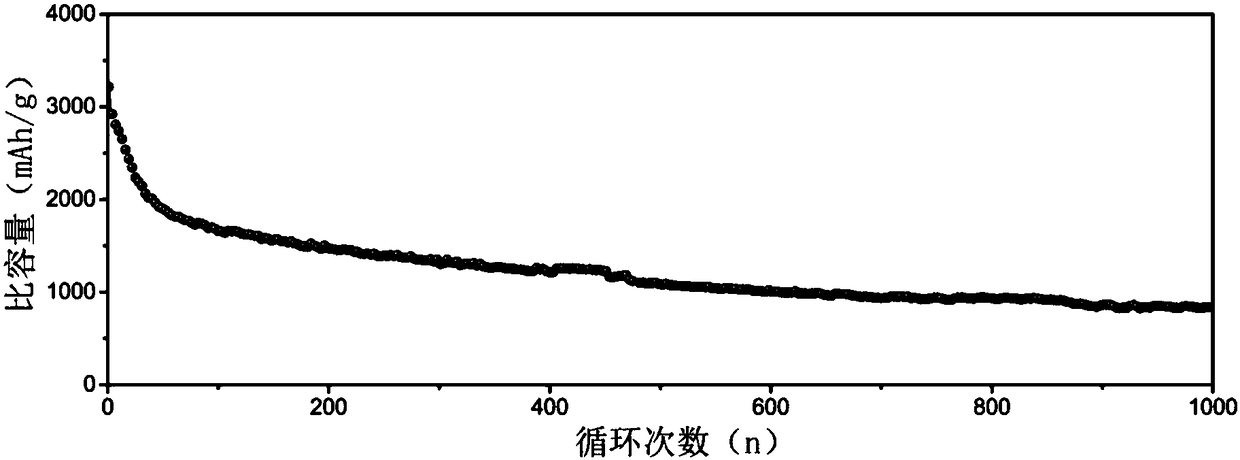

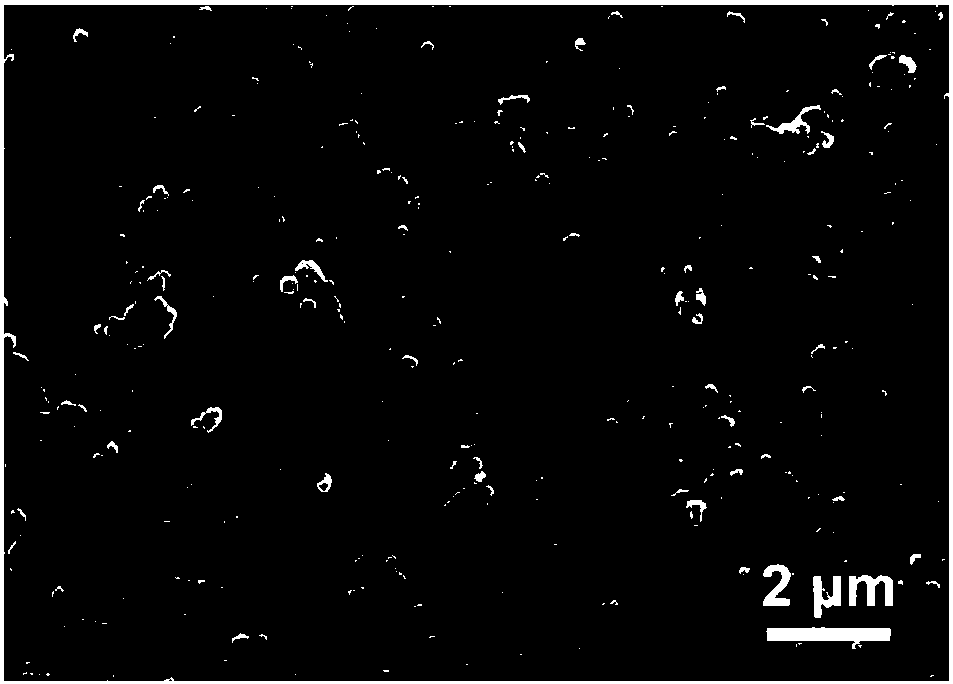

[0026] Silicon nanoparticles were left untreated. Silicon nanoparticles (0.05g), konjac glucomannan (0.025g), conductive agent (Super P, 0.025g) were dispersed in 4ml of water, and stirred for 12 hours. Coat the reconciled slurry evenly on the copper foil, and dry it under vacuum at 45°C for 24 hours. After drying, the pole piece was cut and transferred to the glove box, and the lithium piece was used as the counter electrode to assemble into a 2032 button battery. The electrolyte is 1M LiPF 6 It is PC / EC (volume ratio 1:1) solution of electrolyte, and FEC additive with a mass fraction of 5% is added. Finally, the button battery is subjected to a constant current charge and discharge test, wherein the current density is 2A / g, and the voltage window is 0.01-2V. figure 1 It shows that the battery exhibits excellent cycle performance when using konjac glucomannan as the binder and silicon nanoparticles without any treatment as the active material, and the specific capacity rem...

Embodiment 2

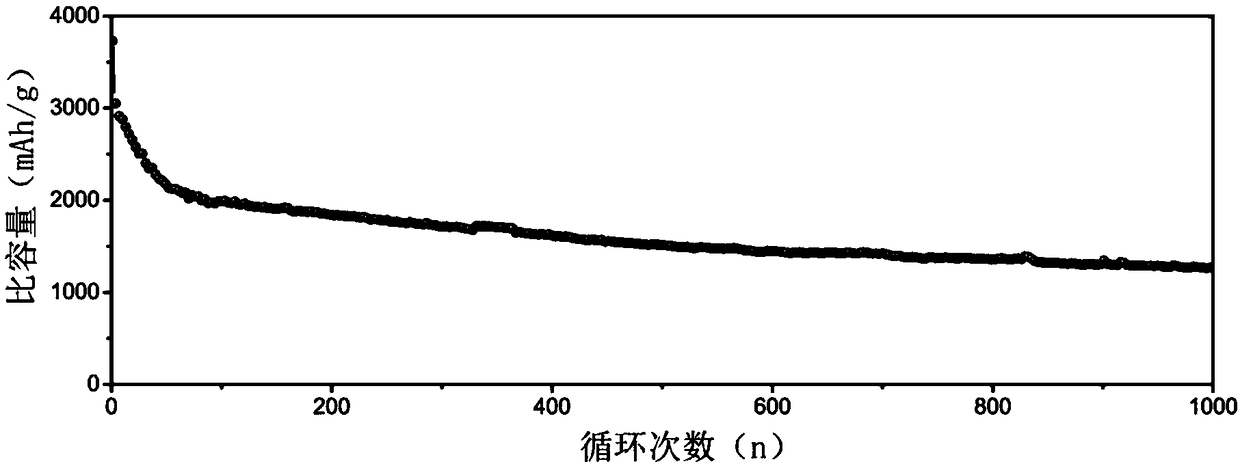

[0028] Silicon nanoparticles (2g) were put into hydrogen peroxide / sulfuric acid mixture (100ml, volume ratio 3:7), and stirred at 80°C for 2 hours. The stirred product was centrifuged at 10,000 rpm, and the obtained precipitate was washed with water for 10 times at 10,000 rpm. Then dried at 80 degrees Celsius to obtain hydroxyl-modified silicon nanoparticles. Hydroxyl-modified silicon nanoparticles (0.05 g), konjac glucomannan (0.025 g), and conductive agent (Super P, 0.025 g) were dispersed into 4 ml of water, and stirred for 12 hours. Coat the reconciled slurry evenly on the copper foil, and dry it under vacuum at 45°C for 24 hours. After drying, the pole piece was cut and transferred to the glove box, and the lithium piece was used as the counter electrode to assemble into a 2032 button battery. The electrolyte is 1M LiPF 6 It is PC / EC (volume ratio 1:1) solution of electrolyte, and FEC additive with a mass fraction of 5% is added. Finally, the button battery is subject...

Embodiment 3

[0030] Silicon nanoparticles (0.3 g) were ultrasonically dispersed in ethanol (360 ml) for 1 hour. Concentrated ammonia water (6ml), water (30ml) and 3-aminopropyltriethoxysilane (0.3ml) were added successively, and stirred at room temperature for 1.5 hours. The stirred product was centrifuged at 10000 rpm, and the obtained precipitate was washed 6 times with ethanol at 10000 rpm. Then dried at 80 degrees Celsius to obtain amino-modified silicon nanoparticles. Amino-modified silicon nanoparticles (0.05 g), konjac glucomannan (0.025 g), conductive agent (Super P, 0.025 g) were dispersed into 4 ml of water, and stirred for 12 hours. Coat the reconciled slurry evenly on the copper foil, and dry it under vacuum at 45°C for 24 hours. After drying, the pole piece was cut and transferred to the glove box, and the lithium piece was used as the counter electrode to assemble into a 2032 button battery. The electrolyte is 1M LiPF 6 It is PC / EC (volume ratio 1:1) solution of electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com