Ultralow-temperature epoxy cured polyester resin and preparation method thereof

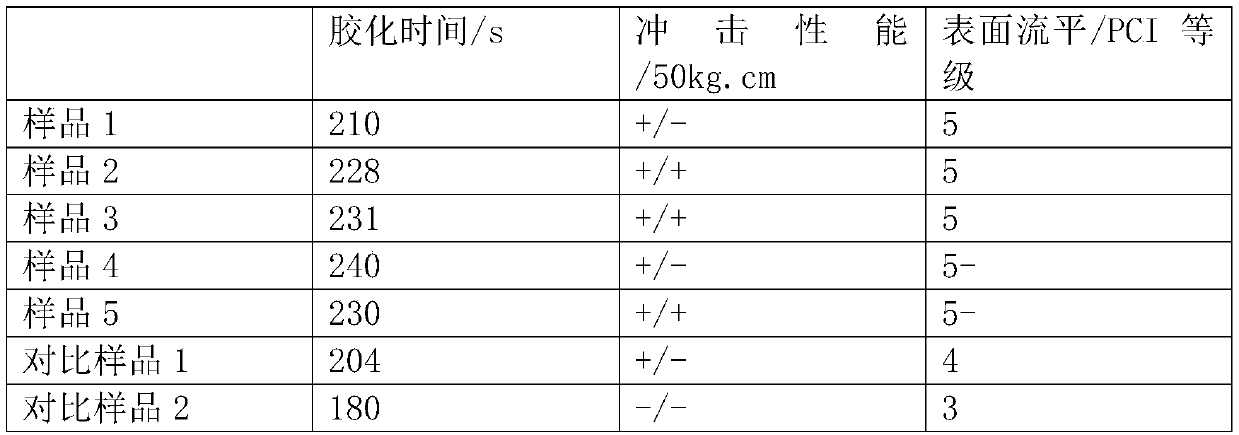

A polyester resin, ultra-low temperature technology, applied in the field of coating chemistry, can solve the problems of large paint baking equipment cost and energy input, low glass transition temperature of synthetic polyester, easy oxidation, etc., to achieve favorable melt flow curing, excellent impact performance , The effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with specific embodiments.

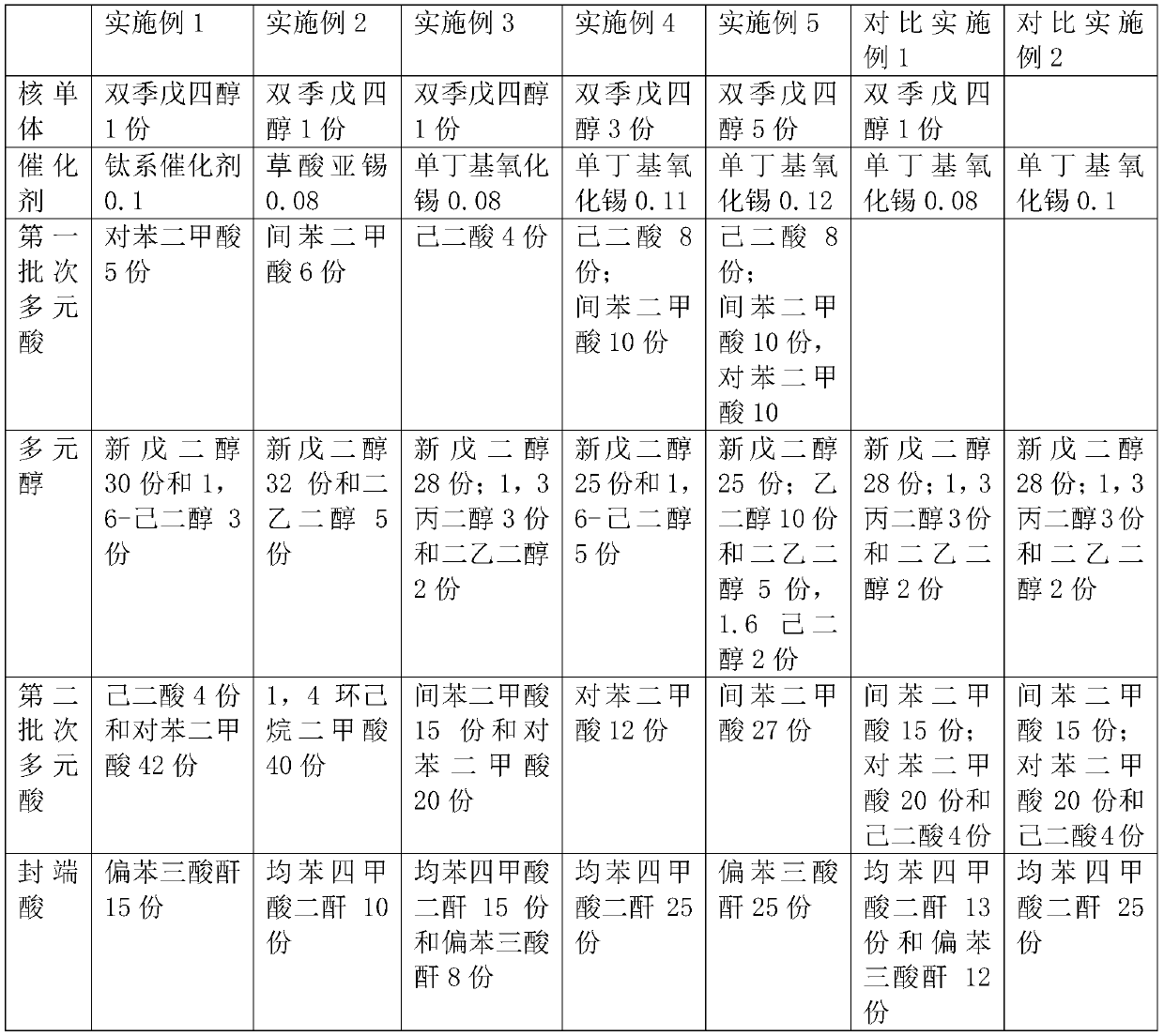

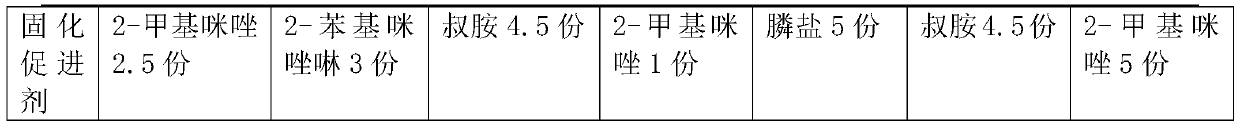

[0031] An ultra-low temperature epoxy-cured polyester resin, the formula of which includes: 1-5 parts of core monomer dipentaerythritol, 0.08-0.12 parts of catalyst, 30-55 parts of polyacid, 30-42 parts of polyol, capping acid 10-25 parts, 1-5 parts of curing accelerator. The core monomer of the present invention selects dipentaerythritol. Compared with pentaerythritol and trimethylolpropane, dipentaerythritol has more hydroxyl groups, so it has more branching and active end groups. will perform better.

[0032] As an example, the catalyst includes: monobutyl tin oxide, stannous oxalate, titanium series catalyst. Polyacids include: terephthalic acid, isophthalic acid, adipic acid, 1,4 cyclohexanedicarboxylic acid. Polyols include: neopentyl glycol, 1,6-hexanediol, ethylene glycol, diethylene glycol, propylene glycol, 1,4 cyclohexanedimethanol, trimethylolpropane. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com