Positive electrode active material, lithium ion battery and preparation method thereof

A positive electrode active material and lithium-ion battery technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of increasing the production cost of lithium-ion batteries, limiting lithium-ion batteries, and low volume density, and achieving commercial The effect of modernized production and application, simple process and high volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

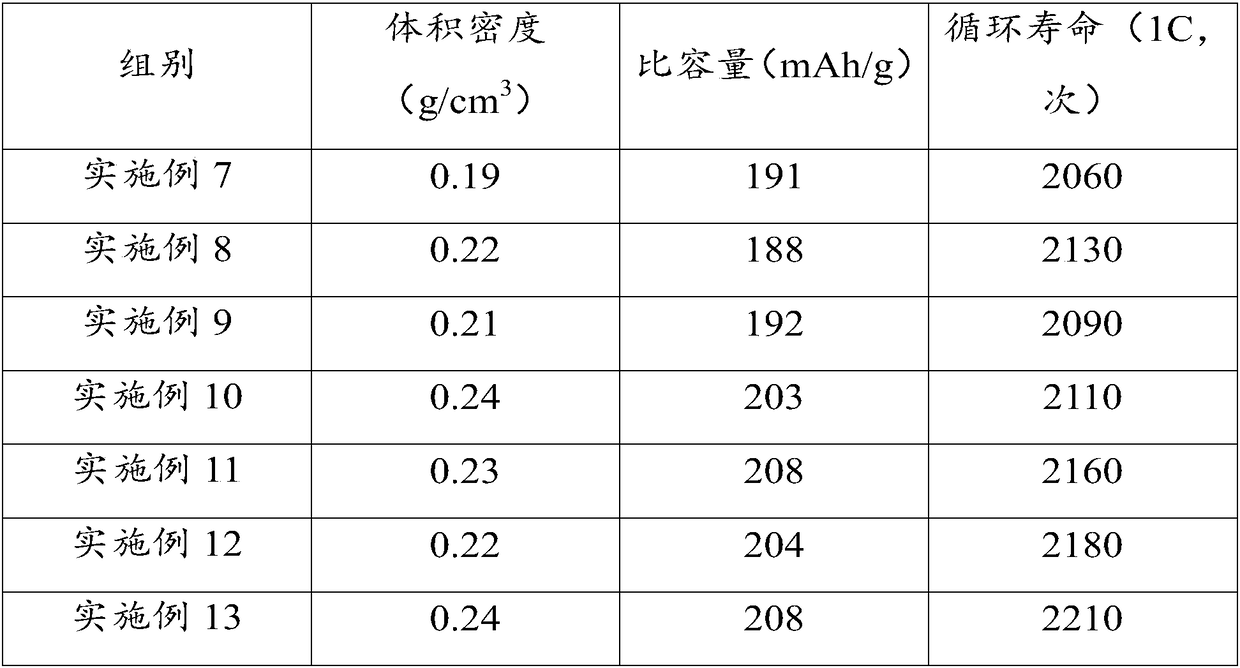

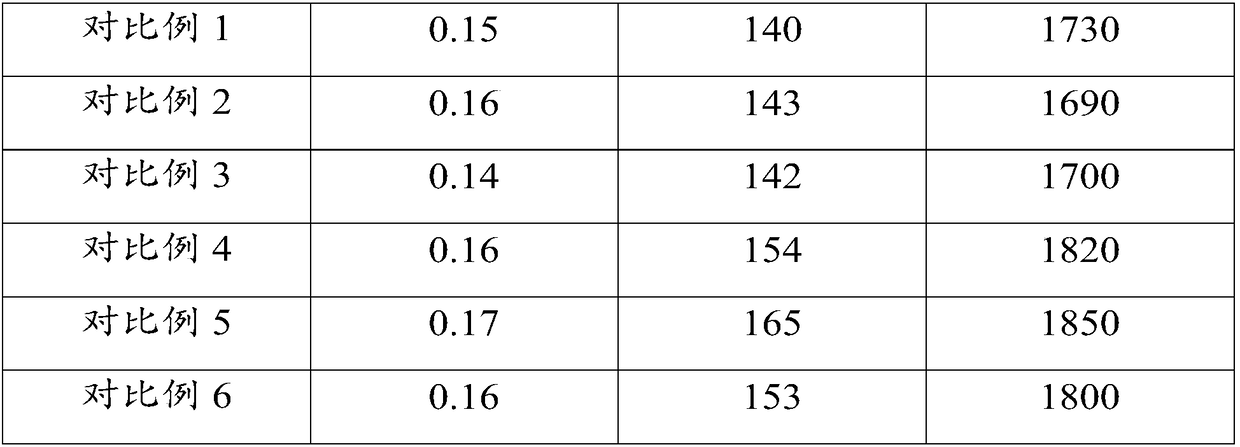

Examples

preparation example Construction

[0054] In a third aspect, in at least one embodiment, a method for preparing the above-mentioned lithium-ion battery is provided, comprising the following steps: (a) coating the positive electrode material and the negative electrode material comprising the positive electrode active material on the positive electrode current collector and the negative electrode material, respectively. Both sides of the negative electrode current collector are then dried and compacted to form positive and negative electrodes;

[0055] (b) Assembling the positive electrode sheet and the negative electrode sheet into a battery cell according to the required size;

[0056] (c) Putting the electric core into the casing, then injecting electrolyte solution into the casing, and then sealing to obtain the lithium ion battery.

[0057] The preparation method of the above-mentioned lithium-ion battery is simple in process, scientific and reasonable, and the prepared lithium-ion battery has the advantages...

Embodiment 1

[0062] A positive electrode active material, comprising 6 parts by mass of a 532-type ternary material, 1 part by mass of lithium iron manganese phosphate and 1 part by mass of lithium manganate;

[0063] The chemical formula of the 532 type ternary material is LiNi 0.5 mn 0.3 co 0.2 o 2 ; The chemical formula of lithium manganese iron phosphate is LiMn 0.5 Fe 0.5 PO 4 .

Embodiment 2

[0065] A positive electrode active material, comprising 8 parts by mass of a 532-type ternary material, 3 parts by mass of lithium iron manganese phosphate and 3 parts by mass of lithium manganate;

[0066] The chemical formula of the 532 type ternary material is LiNi 0.5 mn 0.3 co 0.2 o 2 ; The chemical formula of lithium manganese iron phosphate is LiMn 0.95 Fe 0.05 PO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com