Composite powder as well as preparation method and application of composite powder

A composite powder and drug core wire technology, applied in transportation and packaging, metal processing equipment, coating and other directions, can solve the problems of increasing the complexity of the inorganic-organic composite powder preparation process, and achieve low cost, process flow and, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the coat of the drug core wire material is stainless steel, and the drug core is SiO 2 Particles are prepared by arc spraying process, and the composite powder is collected in the atmospheric environment. The specific steps are: adding SiO with a weight ratio of 20% to the stainless steel strip 2 Particles, prepare a drug core wire with a diameter of 1.97mm, and use arc spraying. The specific parameters are: current 120A, voltage 40V, compressed air pressure 0.8MPa, prepare composite powder, and collect the prepared composite powder in the atmosphere;

[0038] Carry out following performance test to the coating of above-mentioned preparation:

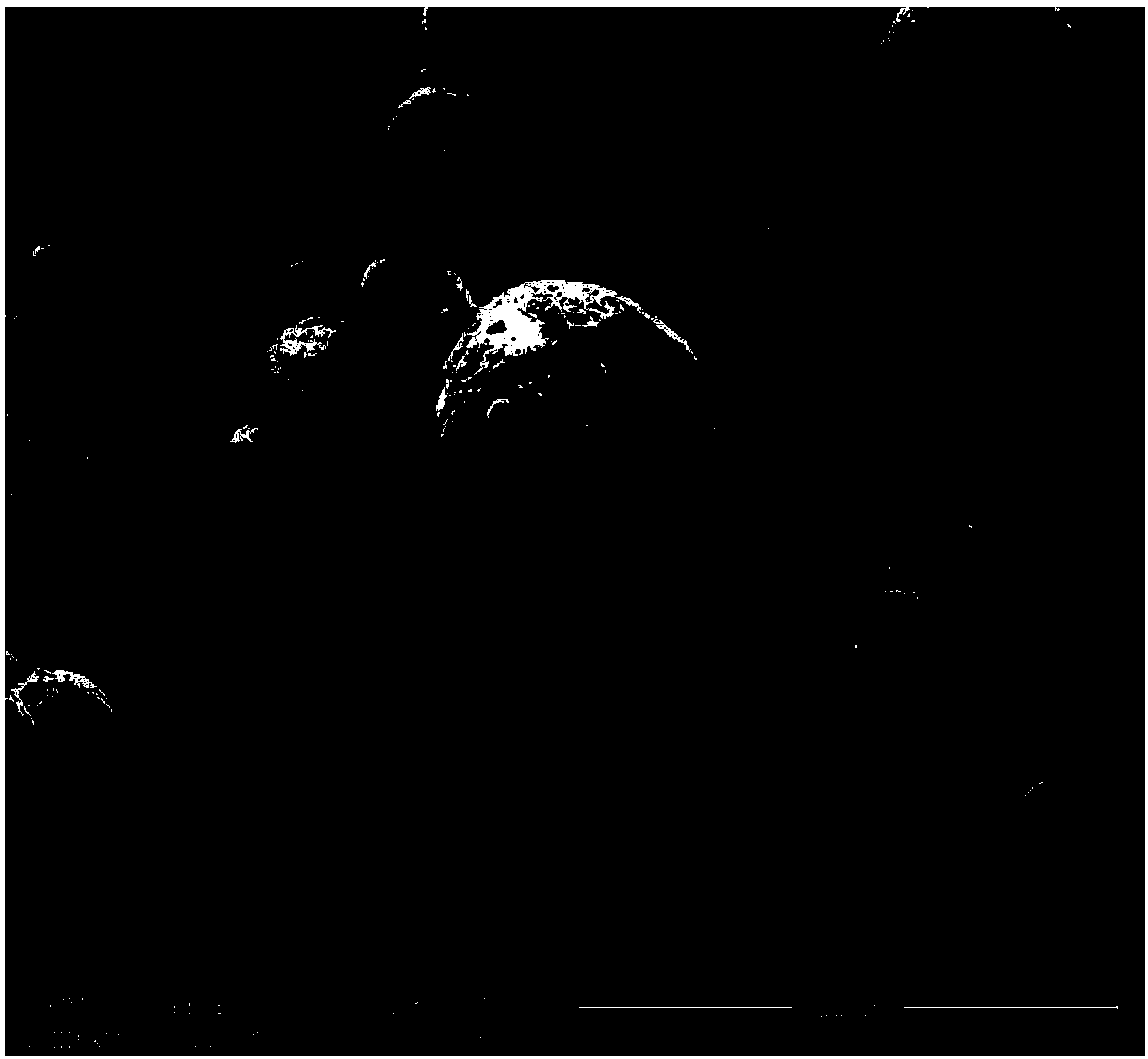

[0039] (1) Observation of the cross-sectional microstructure of the composite powder: the microscopic morphology of the particle cross-section was detected by a field emission scanning electron microscope (SEM), and it was confirmed that the particles contained SiO 2 .

[0040] (2) Observation of the surface...

Embodiment 2

[0042] In this embodiment, the coat of the drug core wire material is stainless steel, and the drug core is polytetrafluoroethylene particles and SiO 2 The particles are prepared by arc spraying process, and the atmosphere protects the environment to collect the composite powder. The specific steps are: adding 4% polytetrafluoroethylene particles and 16% SiO in the stainless steel strip 2 Particles, prepare a drug core wire with a diameter of 1.97mm, and use arc spraying. The specific parameters are: current 120A, voltage 40V, nitrogen pressure 0.8MPa, prepare composite powder, and collect the prepared composite powder in an atmosphere protected environment;

[0043] Carry out following performance test to the coating of above-mentioned preparation:

[0044] (1) Observation of the cross-sectional microstructure of the composite powder: the microscopic morphology of the particle cross-section was detected by a field emission scanning electron microscope (SEM), and it was confir...

Embodiment 3

[0047] In this example, the coat of the drug core wire is made of stainless steel, and the drug core is made of polyperfluoroethylene propylene particles and aluminum particles. It is prepared by arc spraying process, and the composite powder is collected in an atmospheric environment. The specific steps are: adding a weight ratio of 10% FEP particles and 10% micron aluminum powder were used to prepare a drug core wire material with a diameter of 1.97mm, which was sprayed by electric arc. The specific parameters were: current 120A, voltage 30V, compressed air pressure 1.4MPa, prepared Composite powder, the prepared composite powder is collected in the atmospheric environment;

[0048] Carry out following performance test to the coating of above-mentioned preparation:

[0049] (1) Observation of the cross-sectional microstructure of the composite powder: The microscopic morphology of the particle cross-section was detected by a field emission scanning electron microscope (SEM),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com