Production apparatus for synthetic pigment indigo carmine

A technology for synthesizing pigments and production equipment, which is applied in the direction of bisindole indigo indigo dyes, etc., and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0009] Production raw materials and dosage

industrial grade

30

industrial grade

350

industrial grade

25

industrial grade

90

industrial grade

12

industrial grade

80

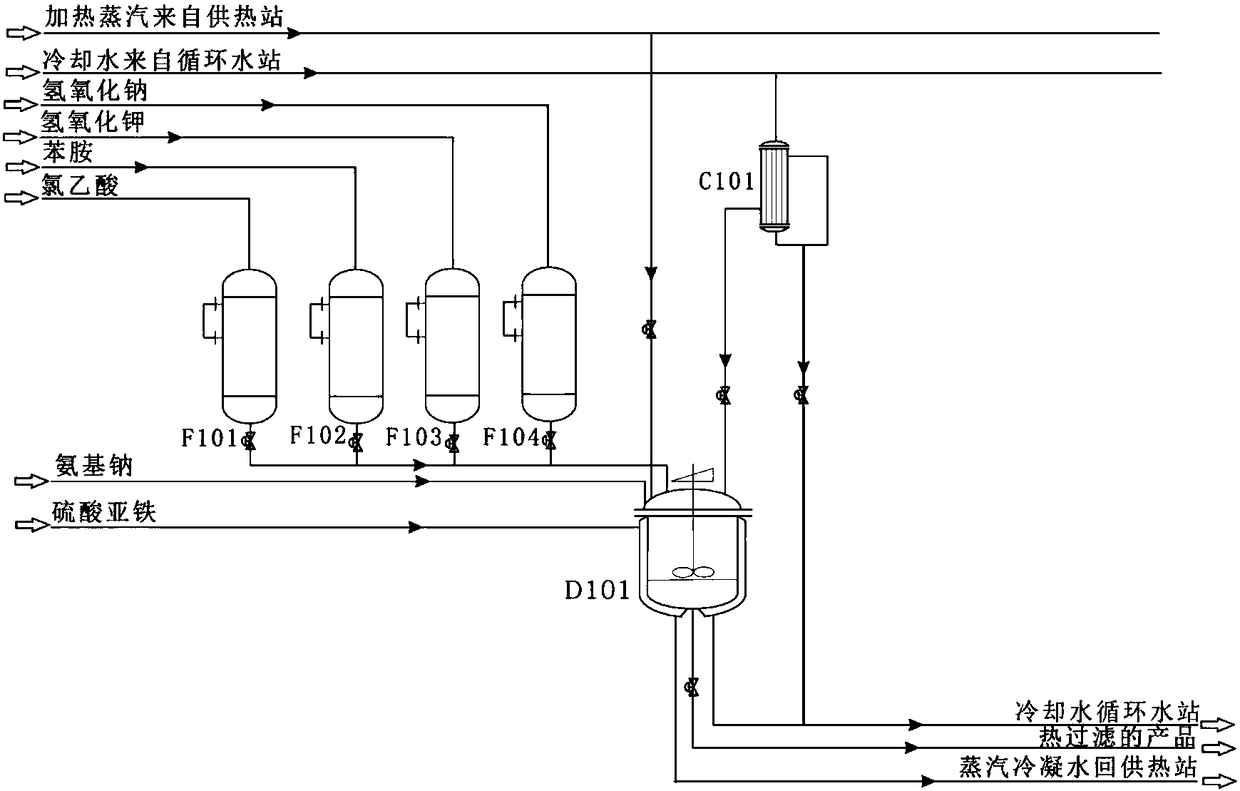

[0011] The production equipment for synthetic pigment sulfonated indigo mainly includes: storage tank 1 (F101), storage tank 2 (F102), storage tank 3 (F103), reaction kettle (D101), condenser (C101), storage tank 4 (F104 ), the connection relationship between the various components of the production device is: storage tank 1 (F101) is connected to the reactor (D101), storage tank 2 (F102) is connected to the reactor (D101), storage tank 3 (F103) It is connected with the reaction kettle (D101), the storage tank 4 (F104) is connected with the reaction kettle (D101), and the condenser (C101) is connected with the reaction kettle (D101); ...

example 2

[0016] Production raw materials and dosage

industrial grade

30

industrial grade

350

industrial grade

30

industrial grade

90

Potassium hydroxide

industrial grade

16

industrial grade

80

[0018] The production equipment for synthetic pigment sulfonated indigo mainly includes: storage tank 1 (F101), storage tank 2 (F102), storage tank 3 (F103), reaction kettle (D101), condenser (C101), storage tank 4 (F104 ), the connection relationship between the various components of the production device is: storage tank 1 (F101) is connected to the reactor (D101), storage tank 2 (F102) is connected to the reactor (D101), storage tank 3 (F103) It is connected with the reaction kettle (D101), the storage tank 4 (F104) is connected with the reaction kettle (D101), and the condenser (C101) is connected with the reaction kettle (D101); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com