A shadow shooting system and method capable of realizing ultra-high speed, high resolution and large field of view

A high-resolution, shooting system technology, applied in the direction of material analysis, material excitation analysis, material analysis through optical means, etc., can solve problems such as distortion, blurred pictures, blurred shooting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

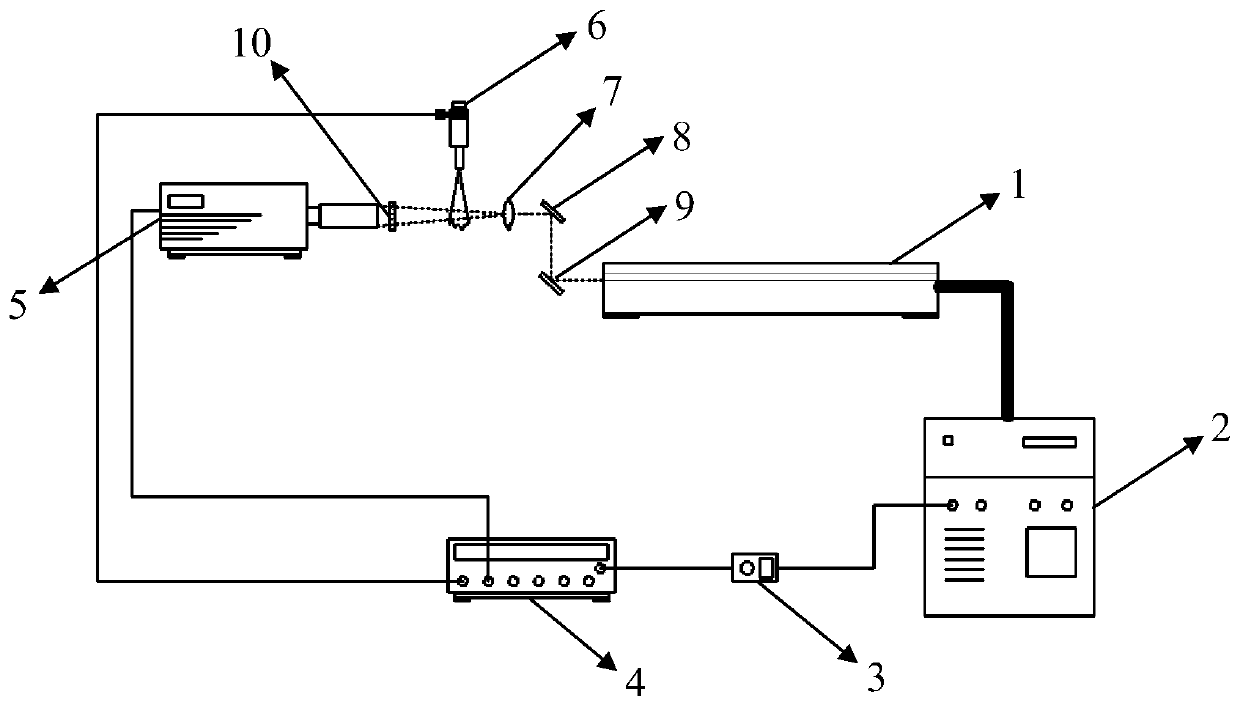

[0013] A shadow shooting system capable of achieving ultra-high-speed, high-resolution, and large field of view, including: a pulse laser 1, a mirror 9 sequentially arranged along the pulse laser optical path, an acrylic fluorescent plate 8, a convex lens 7, an oil injector 6, and a 550nm High-pass filter 10, industrial camera 5, laser control cabinet 2 connected to the pulse laser, manual relay switch 3 connected to the laser control cabinet, DG535 digital delay pulse respectively connected to the fuel injector, industrial camera and manual relay switch generator 4;

[0014] The pulsed laser emits pulsed laser energy with a wavelength of 532nm at a frequency of 10 Hz and a pulse duration of 10 ns; the industrial camera is equipped with a microscopic shooting lens, which can magnify the image by 5 times and realize close-range microscopic shooting; the acrylic The fluorescent plate eliminates the speckle (inhomogeneous) phenomenon produced by the laser directly as the backgrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com