Air-assisted adsorption separation method and device

An adsorption separation and gas-assisted technology, which is applied in the field of gas-assisted adsorption separation methods and devices, can solve the problems of difficult recovery of adsorbents, difficulty in continuous adsorption process, inability to apply complex separation systems containing particles, etc., and achieve easy recovery and continuous operation , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

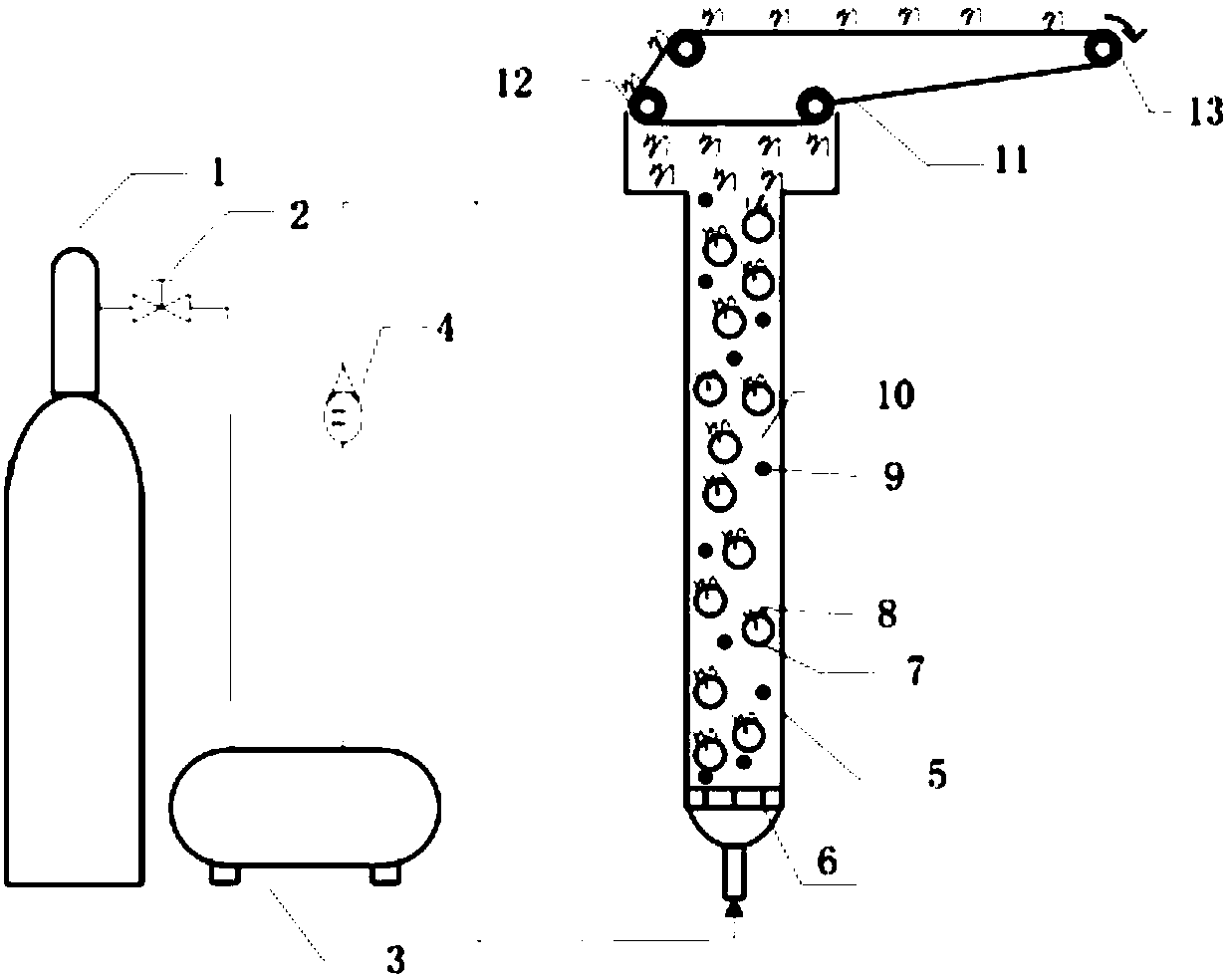

[0024] Congo red, a typical pollutant in printing and dyeing wastewater, was taken as the separation object. use figure 1 The shown gas-assisted adsorption separation device mainly includes an air flotation column 5 (inner diameter 50mm, length 320mm) and an adsorbent film 11 with a gas distributor 6, and the top of the air flotation column 5 is provided with a fixed position pulley 12 and The adsorbent film 11 driven by it, the bottom of the air flotation column 5 is provided with a gas distributor 6, the adsorbent film 11 is driven by the motor drive wheel 13 through the pulley 12, the motor is a variable speed motor with AC or DC input, and the adjustment rate is 0 ~100 rev / min; also includes rotameter, buffer tank and gas cylinder of auxiliary equipment. The rotameter 4 is connected to the gas inlet at the bottom of the air flotation column 5 , and then the gas is delivered to the air flotation column 5 through the gas distributor 6 .

[0025] Utilize above-mentioned gas...

Embodiment 2

[0030] The heavy metal ions in wastewater are used as the separation object. In this experiment, the typical toxic heavy metal ion hexavalent chromium was used as the removal object, and a 3m long and 5cm wide film coated with activated carbon was used as the adsorbent film. 6+ Concentration is 30ppm, take a small amount of CTAB as surfactant.

[0031] The specific operation is: add the prepared heavy metal raw material liquid into the air flotation column 5 until the liquid surface is just in contact with the adsorbent film 11, open the gas valve, adjust the gas flow rate to 60ml / min, and let it pass through the gas distributor 6 continuously Through the air flotation column 5, at the same time, the motor drive wheel 13 is adjusted to drive the adsorbent film 11 to rotate continuously at a speed of 2 r / min, and the air bubbles 7 generated by the injected gas capture the substance to be separated 8 and the surfactant in the feed liquid 10 The composites are passed upward, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com